Endoscope execution mechanism used in float glass molten tin bath and adjusting method of endoscope execution mechanism

A float glass and actuator technology, used in telescopes, optics, instruments, etc., can solve the problems of inability to achieve front and rear translation of the endoscope, narrowing of the observation range of the endoscope, and inability to retract the endoscope, etc. The effect of popularization, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

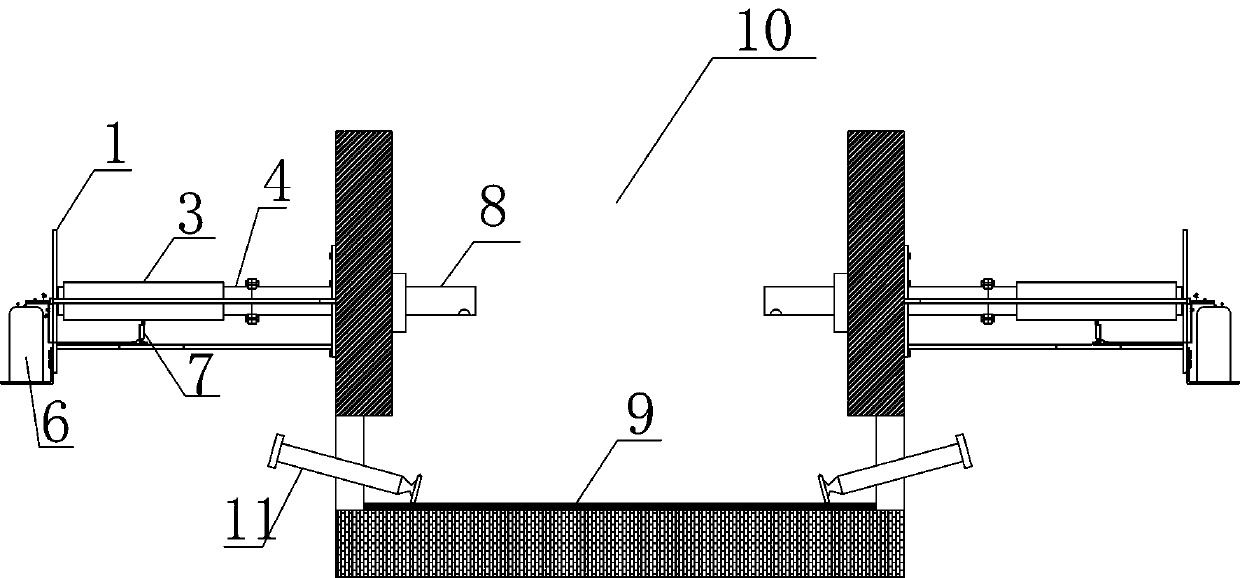

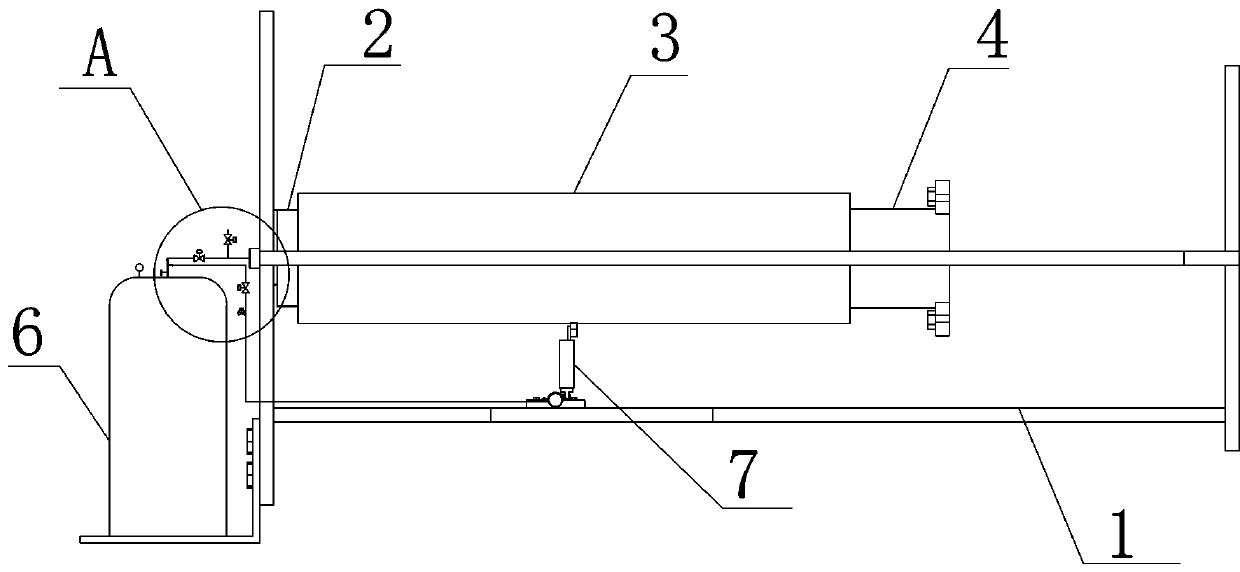

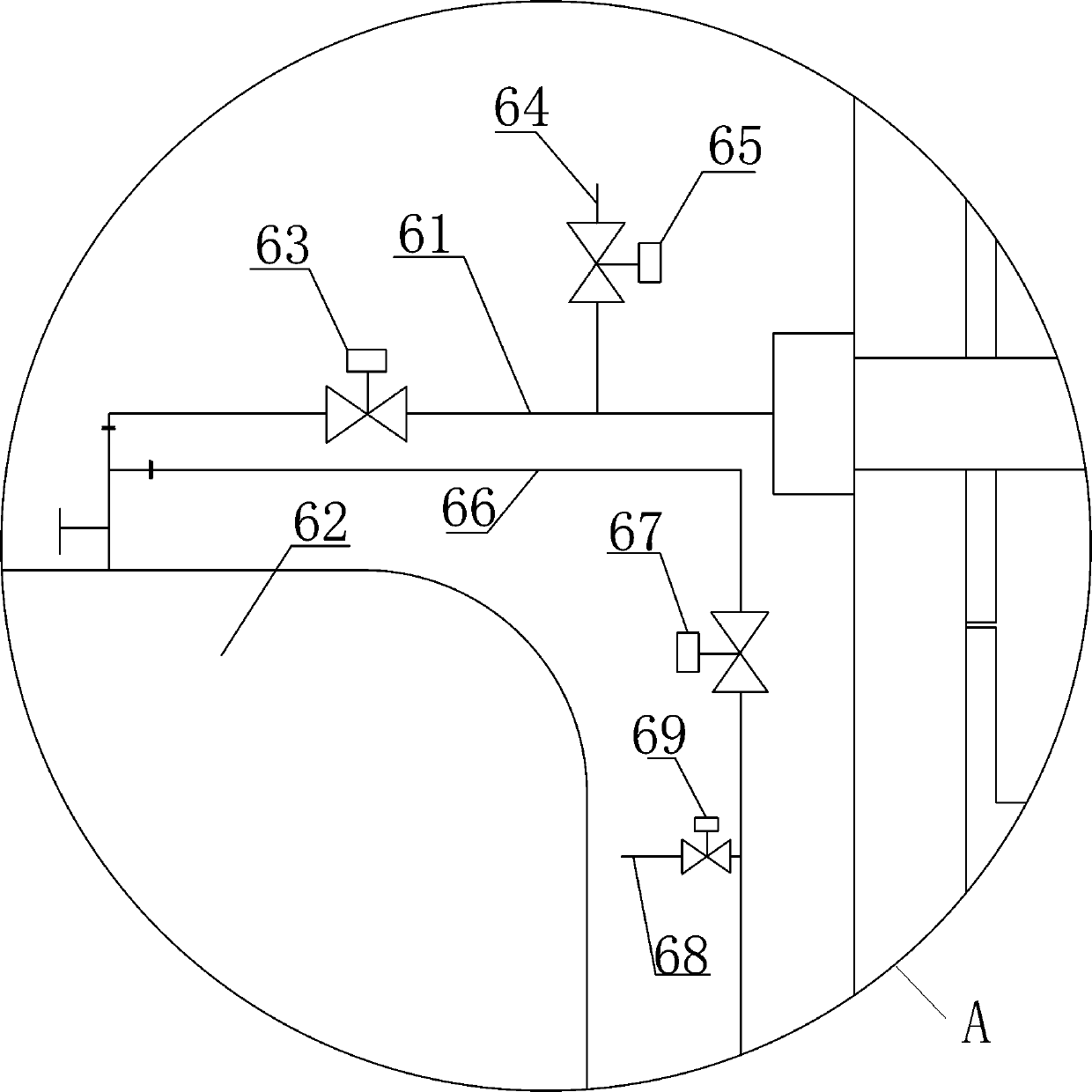

[0038] The preferred solution is as Figure 1 to Figure 12 As shown, an endoscope actuator used in a float glass tin bath includes a supporting frame 1, which is connected to a fixed cylinder 2, and the fixed cylinder 2 is rotatably connected to a rotating outer cylinder 3, and the rotating type The outer cylinder 3 is sleeved with a movable inner column 4, the inner wall of the rotary outer cylinder 3 is provided with an annular tooth groove 31, and the outer wall of the movable inner column 4 is provided with an annular convex tooth 41, and the annular convex tooth 41 is compatible with the annular tooth groove 31 Matching; after the movable inner column 4 is inserted into the rotating outer cylinder 3, a gas chamber 32 is formed in the rotating outer cylinder 3, and an elastic mechanism 5 is arranged in the gas chamber 32, and the elastic mechanism 5 pushes the rotating outer cylinder 3 and the movable inner column 4 are connected to each other; the gas chamber 32 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com