Novel steel drum welding seam flattening device

A new type of technology for steel drums, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of easy deformation of steel drums, inability to achieve synchronous feeding and blanking, deformation of steel drums, etc., to improve work efficiency. , The effect of preventing extrusion deformation and accurately positioning the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

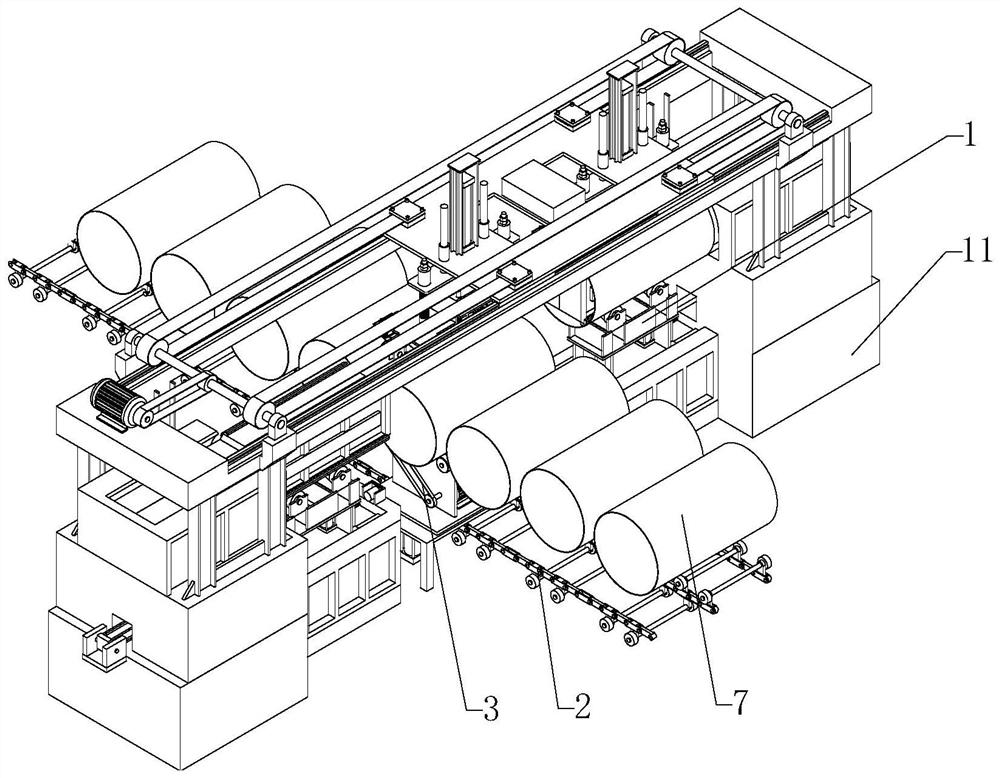

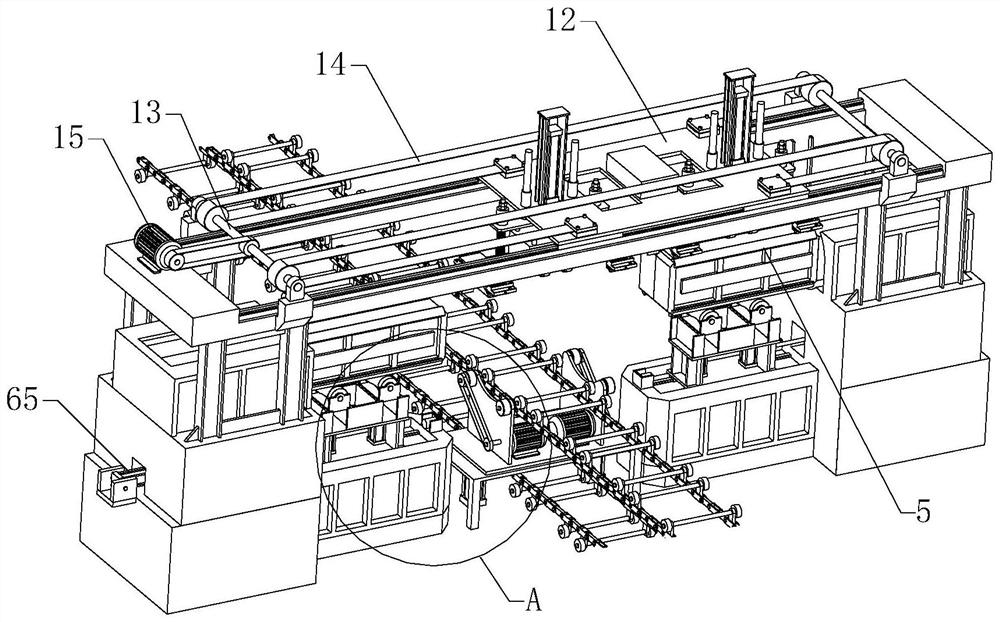

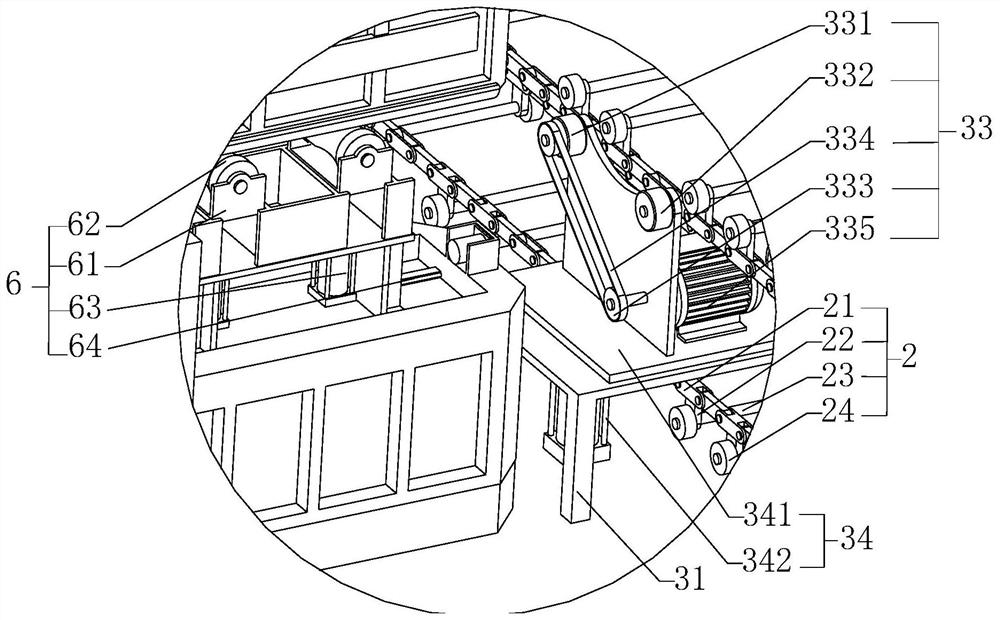

[0031] Embodiment, a kind of novel steel barrel welding seam flattening device, such as figure 1 , figure 2 As shown, it includes a flattening mechanism 1, a transmission mechanism 2 arranged below the flattening mechanism 1, a seam-seeking mechanism 3 is arranged on the transmission mechanism 2, the seam-seeking mechanism 3 is located inside the flattening mechanism 1, and the transmission mechanism 2 includes a transmission chain 14, fixedly connected to the limit seat 22 on both sides of the 14 conveyor chains, the two limit seats 22 are rotated to connect the limit rod 23, and the two ends of the limit rod 23 are rotated to connect the limit roller 24, and the steel drum 7 is located at In the middle of two adjacent limit rods 23, the transmission mechanism 2 transmits the steel drum 7 to the seam-seeking mechanism 3, and the seam-seeking mechanism 3 detects the position of the weld seam of the steel drum 7, and rotates the weld seam of the steel drum 7 to the steel drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com