Automatic assembly equipment with collaborative gesture adjustment, collision prevention and tightening functions

A technology for equipment and collision avoidance, applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of high labor intensity in manual assembly, difficulty in ensuring high-precision fit, heavy workload, etc., and achieve high bolt tightening efficiency, The effect of improving docking efficiency, reducing difficulty and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

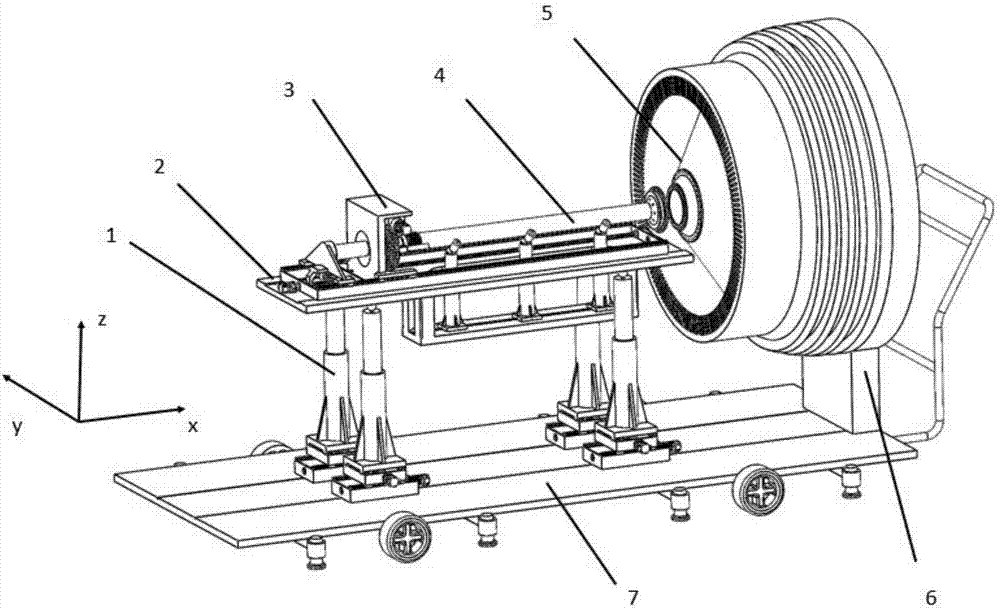

[0027] Such as figure 1 As shown, in this embodiment, the six-degrees-of-freedom coordinated attitude adjustment of the attitude-adjusting dynamic platform 2 is realized through the coordinated movement of the four POGO column mechanisms 1 . The screw tightening device 3 can move along the x direction, so as to realize the automatic connection of bolts on the docking surfaces of the parts to be assembled 4 and the fixed parts 5 . The fixed parts 5 are connected to the transport vehicle 7 through the tooling 6 of the parts to be assembled, and the entire automatic assembly system can follow the movement of the transport vehicle 7 .

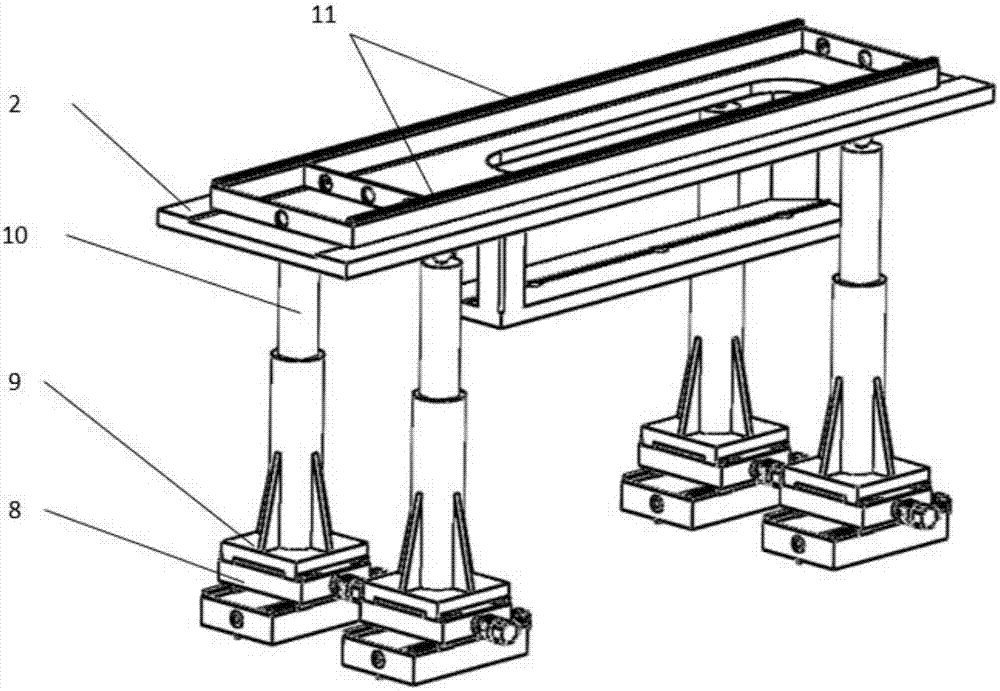

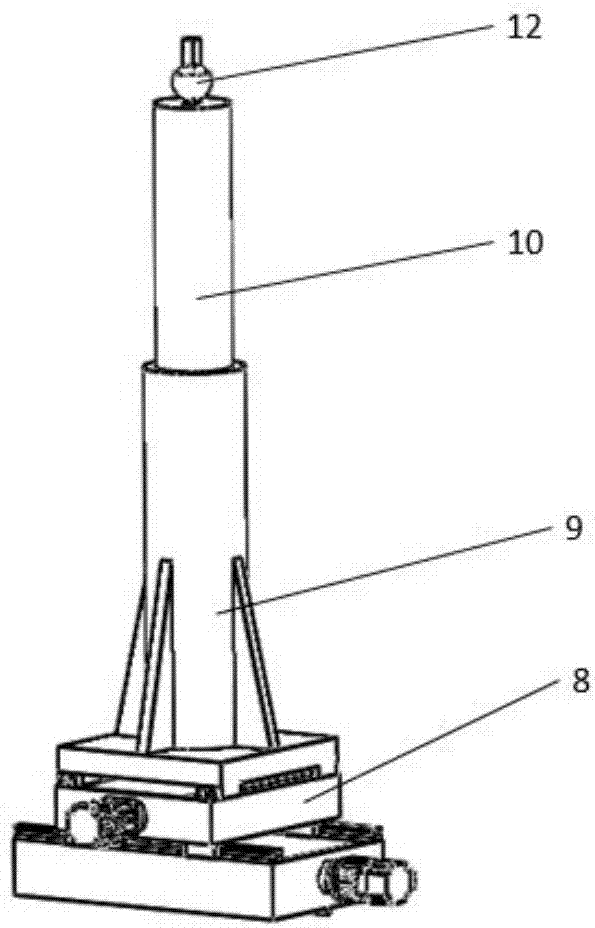

[0028] Such as figure 2 As shown, the POGO column mechanism 1 is set on the transport vehicle 7 through the x-direction mobile platform 8 and the y-direction mobile platform 9, wherein: the x-direction mobile platform 8 can perform a large-scale linear movement in the x direction along the guide rail, and the y direction The mobile platform 9 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com