Lock nut feeding and tightening device for piston assembly production

A technology for locking nuts and piston components, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve the problems of reducing feeding efficiency, reducing production efficiency, and low tightening efficiency, so as to improve tightening efficiency and positioning effect , Guarantee the effect of positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

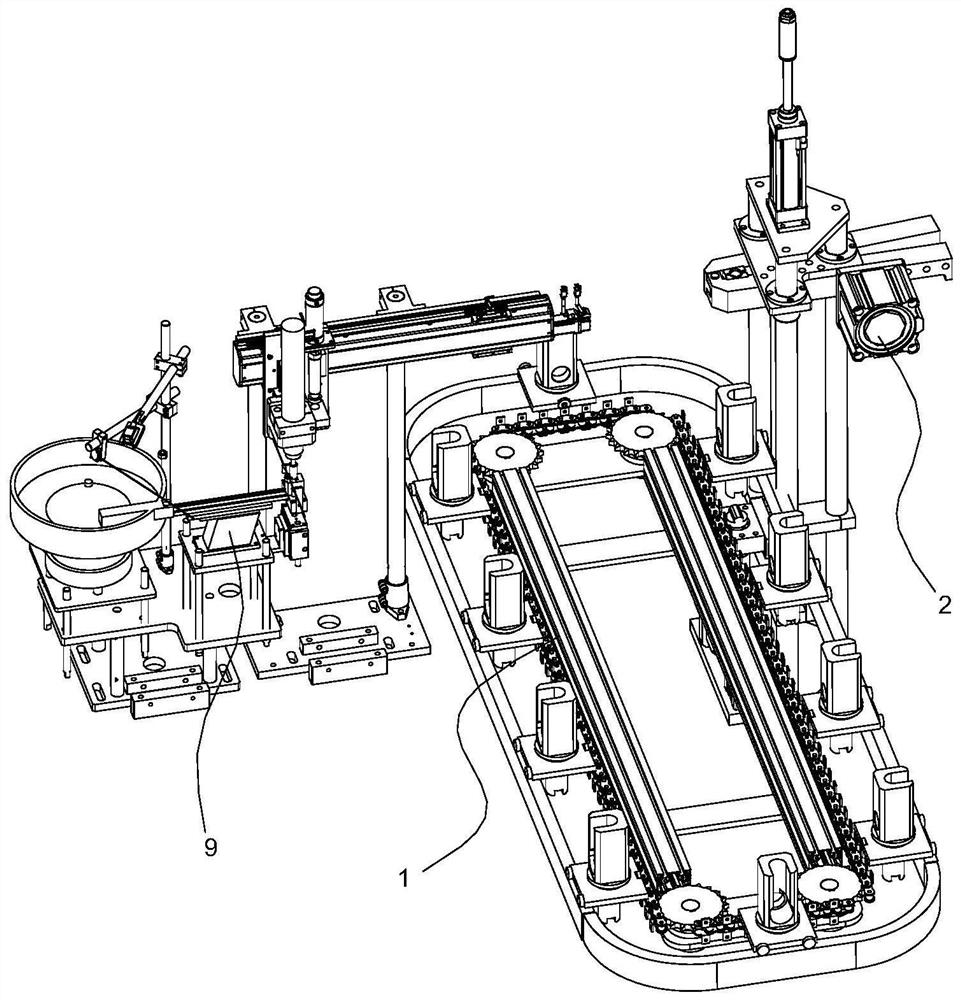

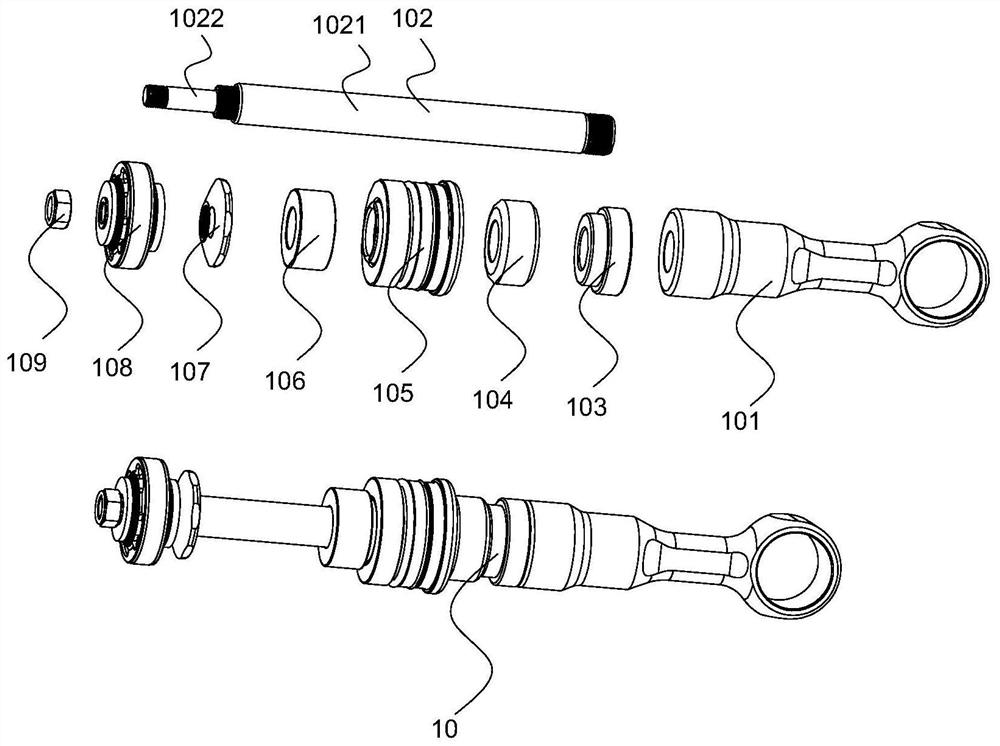

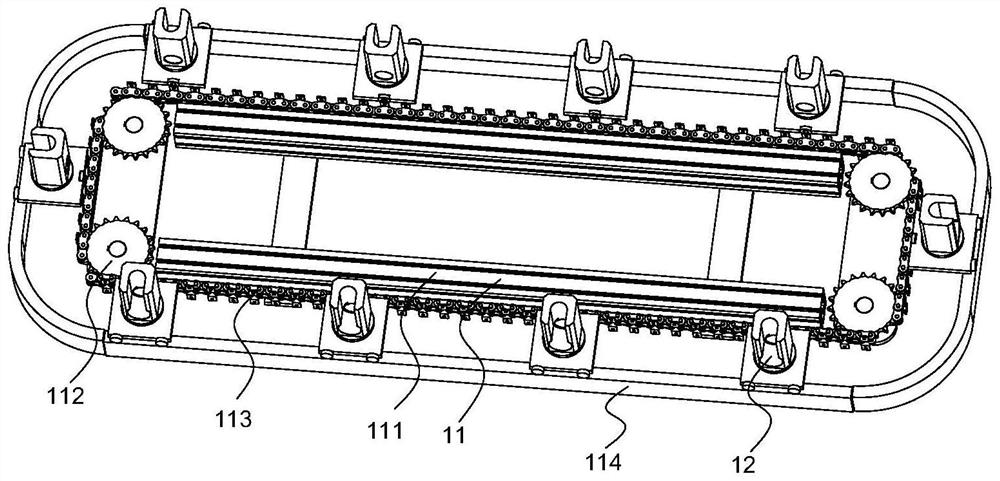

[0031] Such as figure 1As shown, a hydraulic buffer piston assembly assembly equipment includes a turntable assembly device 1 , a mandrel tightening device 2 and a lock nut feeding and tightening device 9 . The turntable assembly device 1 is provided with a mandrel tightening station and a locking nut feeding and tightening station. The position of the mandrel tightening device 2 matches the mandrel tightening station. The position of the locking nut feeding and tightening device 9 is matched with the locking nut feeding and tightening station. The mandrel tightening device 2 is used for vertically tightening the mandrel on the connector. The locking nut feeding and tightening device 9 is used for feeding the locking nut onto the mandrel, and tightening the locking nut so that the recovery valve is fixed between the limit nut and the locking nut. The lock nut feeding and tightening device 9 adopts a lock nut feeding and tightening device used for piston assembly production....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com