Calculation method for bolt rotation angle method-based tightening process

A calculation method and bolt technology, applied in calculation, computer-aided design, special data processing applications, etc., can solve the problems of long test period, high test repeatability, high cost, etc., and achieve the goal of improving bolt tightening efficiency and ensuring reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

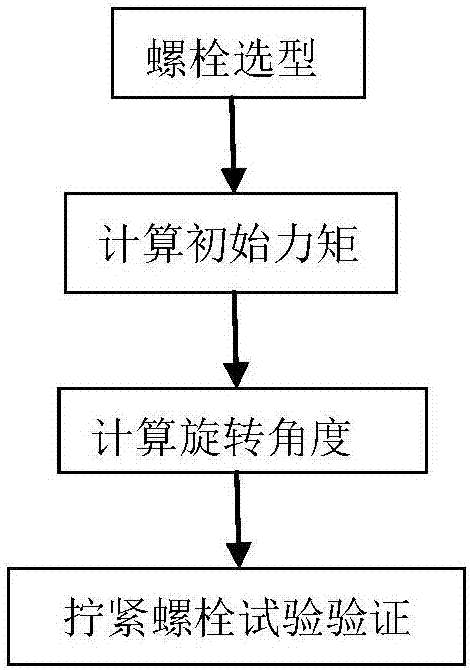

[0027] An embodiment of the present invention provides a calculation method for the bolt rotation angle method tightening process, including the calculation of the initial tightening torque and the calculation of the rotation angle, wherein,

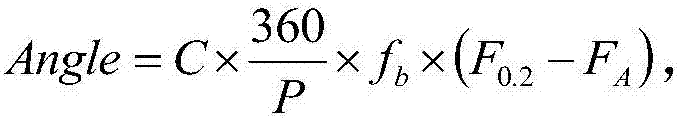

[0028] First calculate the initial moment, the formula for calculating the initial moment is:

[0029] T=0.2×F s ×D,

[0030] Among them, F s Refers to the pre-tightening force under the initial moment, D is the nominal diameter of the thread;

[0031] f s =Z×S 0.2 ×A s , among them, Z is the preload coefficient, the general value is 0.2, S 0.2 is the bolt yield strength, A s refers to the nominal stress cross-sectional area of the bolt, and

[0032] Among them, d 2 is the pitch diameter of the thread, d 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com