Assembly including a ratchet device and a tightening strap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

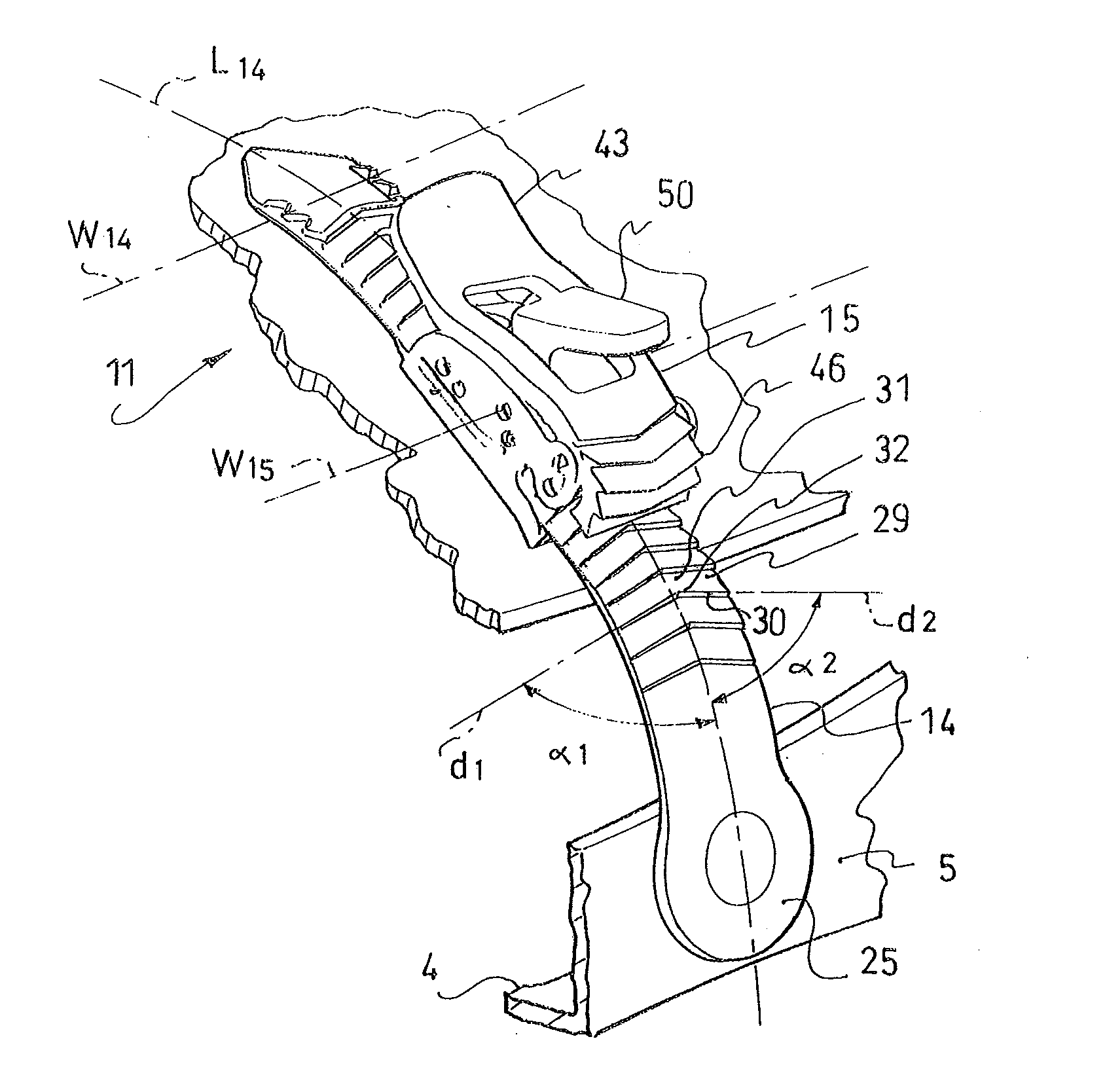

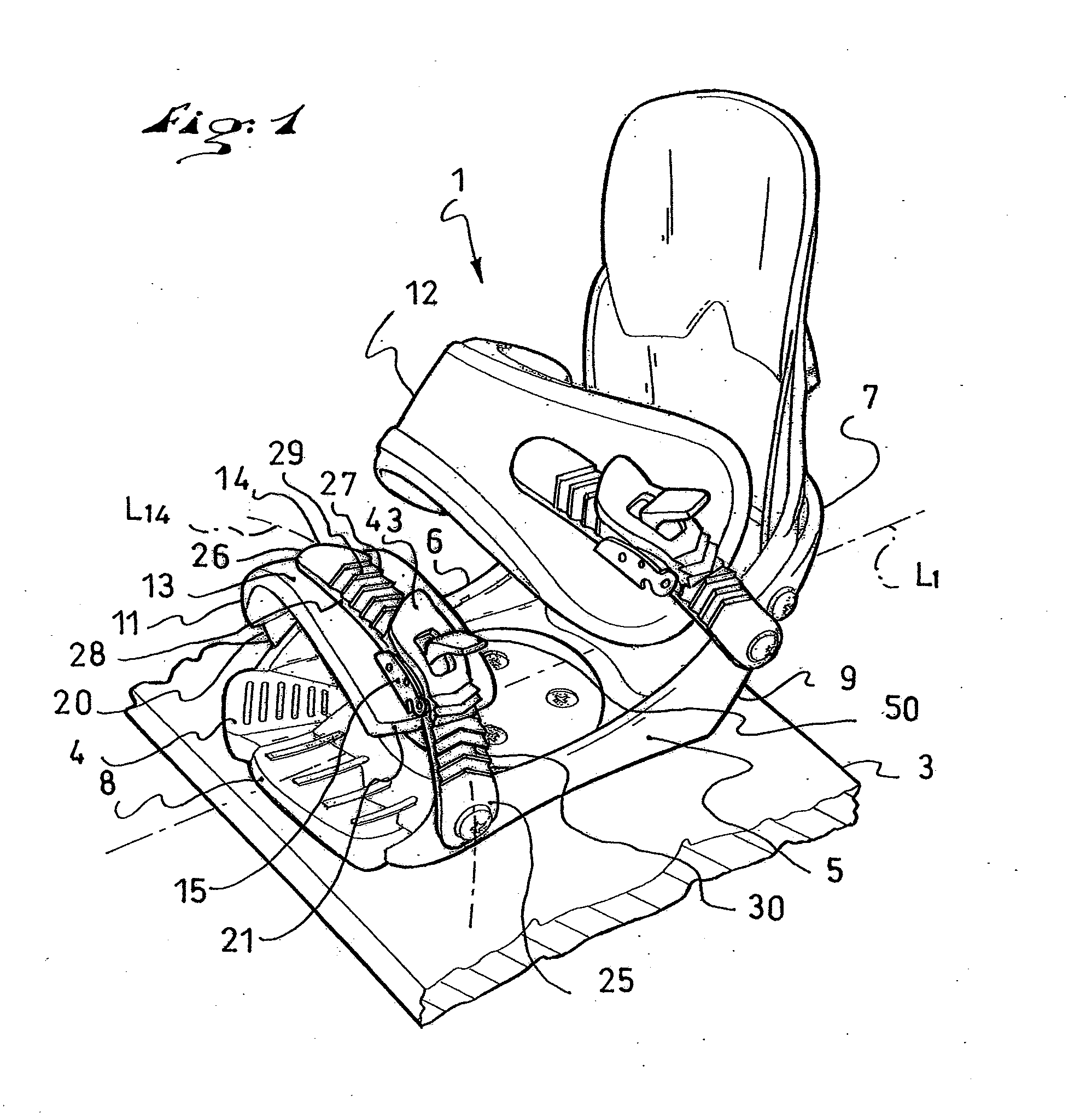

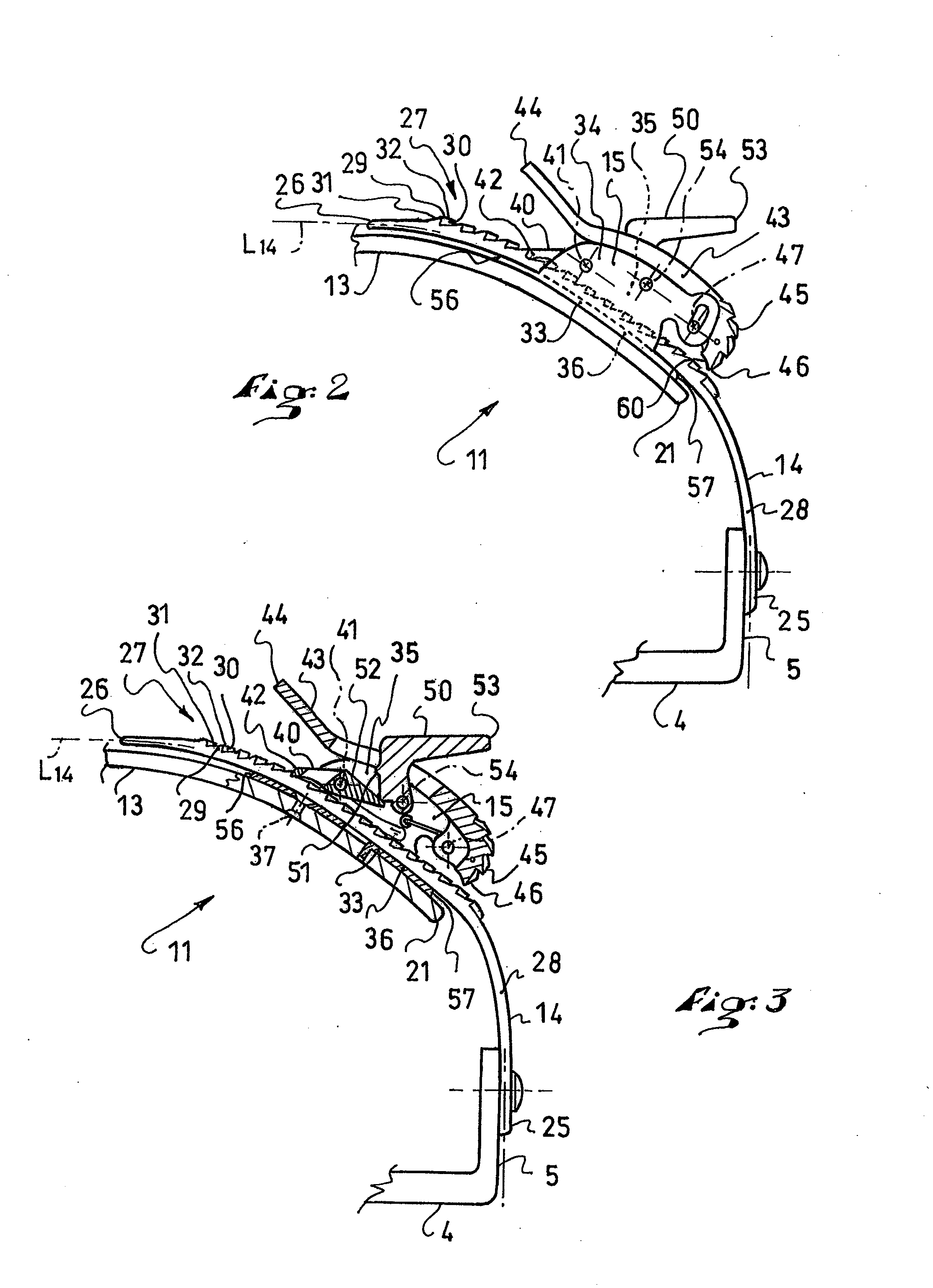

[0037]the invention is described herein with reference to FIGS. 1 to 8.

[0038]As shown in FIG. 1, an assembly includes a snowboard binding 1, in the form of a “strap-in” binding, provided to retain a boot on a snowboard 3. Additional examples of such bindings are disclosed in commonly owned U.S. Pat. No. 6,405,457 and U.S. Pat. No. 7,036,830, and U.S. Patent Application Publication No. 2005 / 0046150, the disclosures of which are hereby incorporated by reference thereto in their entireties.

[0039]In a known manner, the binding 1 has a baseplate 4, as well as a lateral edge 5 and a medial edge 6, the lateral and medial edges extending upwardly from the baseplate, the edges being connected to one another by an arch 7, or heel loop.

[0040]The baseplate 4 extends along a longitudinal direction L1 of the binding, between a front end 8 and a rear end 9.

[0041]A first linkage 11, or strap, and a second linkage 12, or strap, are provided to removably retain the boot on the binding 1. Strap 11 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com