Fast tightening device for screw pair in small space

A thread pair, small space technology, applied in the direction of wrench, manufacturing tools, wrench, etc., can solve the problems of difficulty in tightening nuts, low tightening efficiency, difficulty in applying tightening torque, etc., to achieve improved tightening efficiency, low cost, and easy installation The effect of the lanyard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The present invention designs two parts, the sleeve and the quick loading and unloading wrench, figure 1 Structural diagram when using the present invention.

[0051] The process of using this set of devices to install and remove self-sealing joints:

[0052] (1) in figure 1 As shown, put 2 sleeves on the 3 self-sealing nuts of the servo mechanism 4 redundant tubes. Image 6 The inner hexagon end of the sleeve shown is 47mm and fits with 3 self-sealing nuts, and the opening of the sleeve is 32mm just enough to pass through figure 1 4 redundant tubes in.

[0053](2) in figure 1 As shown, place 1 quick-release wrench over the socket. Figure 5 The socket 46mm hex end shown mates with the wrench head.

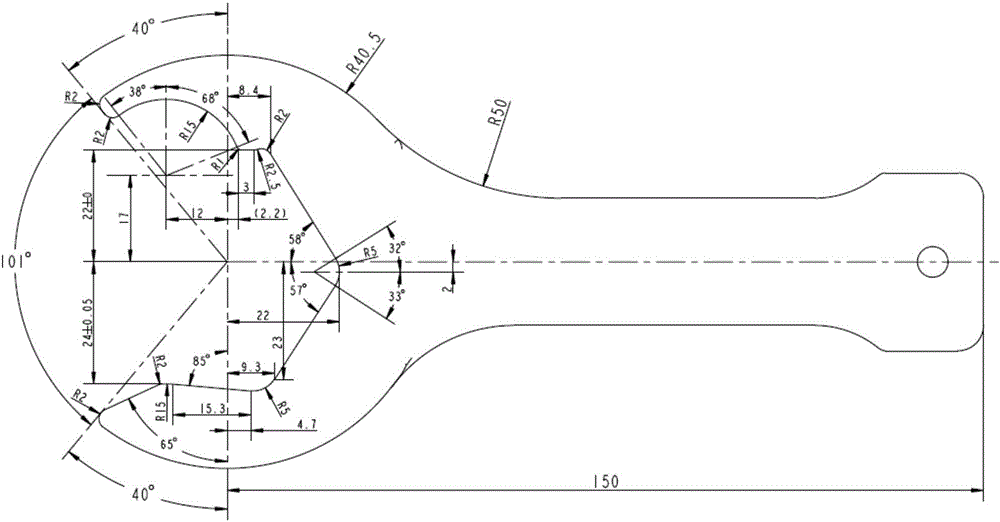

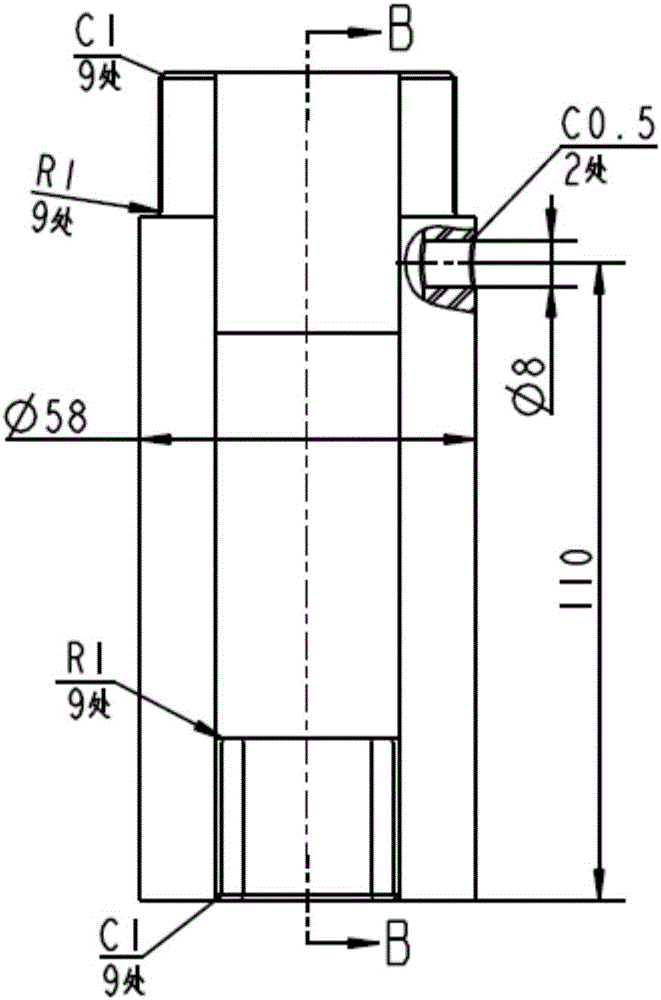

[0054] (3) image 3 and Figure 4 It is a sketch of the overall structure of the sleeve, and its outer diameter, inner hole, outer hexagon, inner hexagon, small hole, height, chamfering, rounding and other design are reasonable.

[0055] (4) When tightening the sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com