Expansion device

A technology of expanding and expanding, applied in the field of expanding devices for expanding and tightening coils, can solve the problems of easy slippage, weak expanding force, affecting the expanding efficiency of the expanding device, etc., so as to improve the expanding efficiency and improve the The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

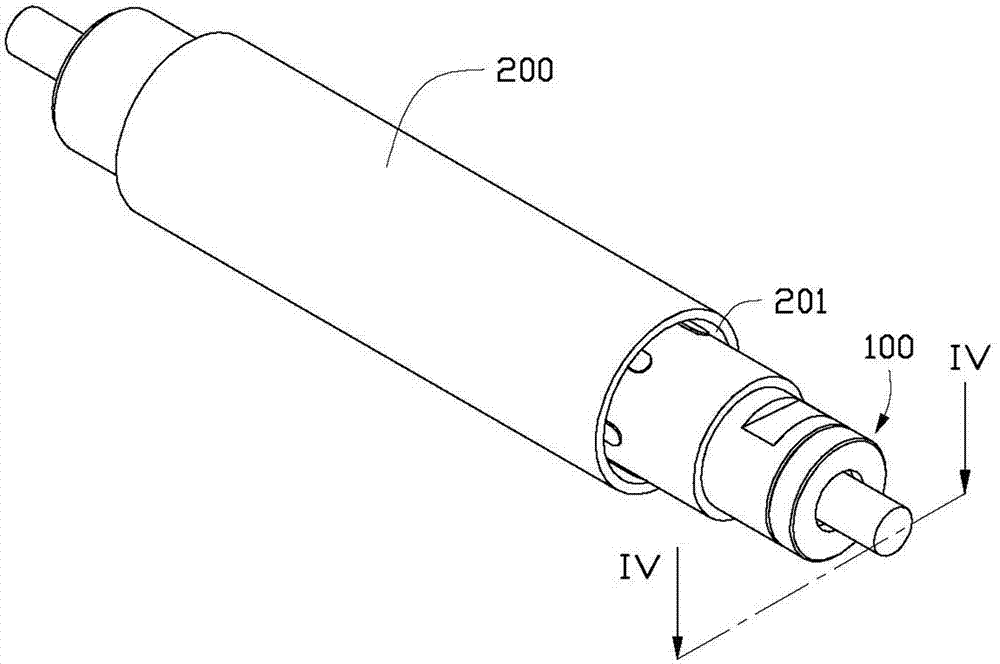

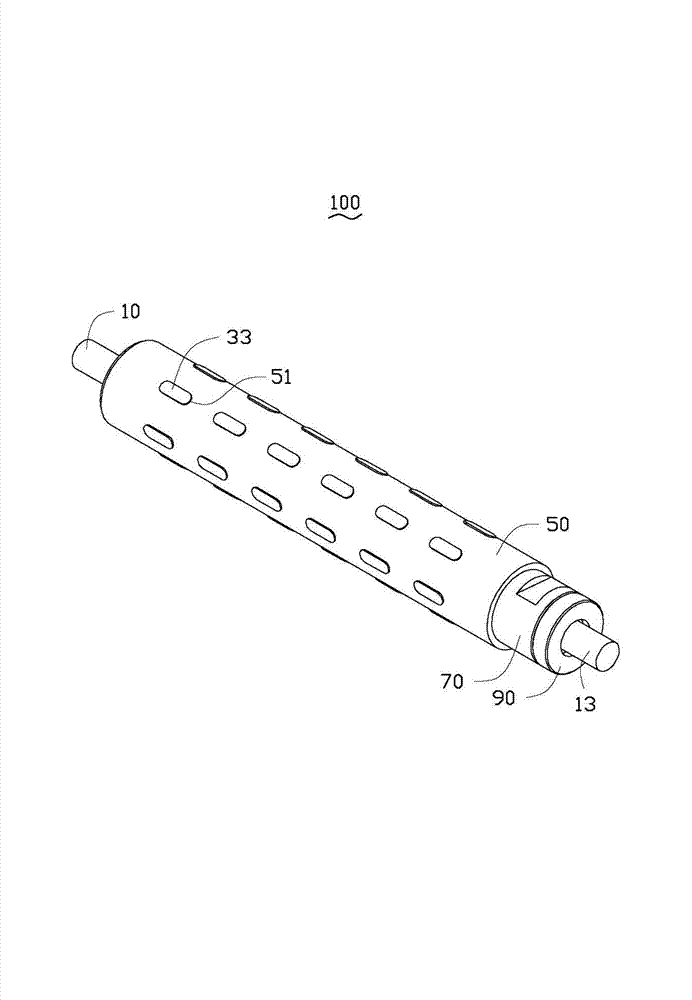

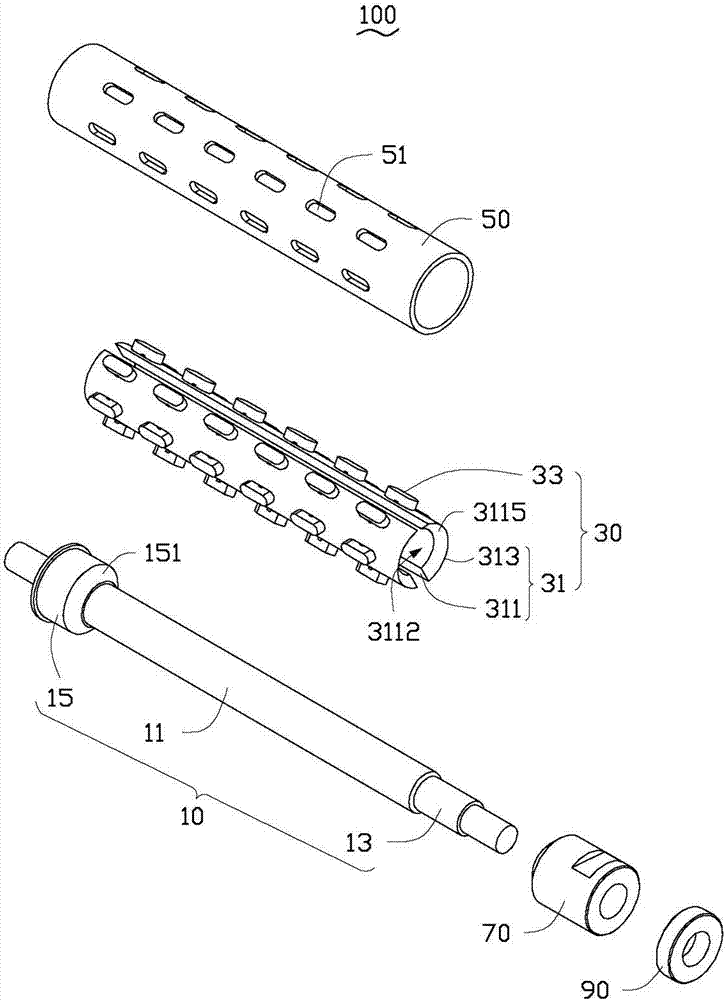

[0014] see figure 1 and figure 2 , the tensioning device 100 of this embodiment is used for tensioning the roll material 200 . The roll material 200 is provided with a roll hole 201 along the axial direction. The tensioning device 100 is passed through the roll hole 201 and abuts against the inner wall of the roll hole 201 so as to expand and tighten the roll material 200 on the tensioning device 100 . The tensioning device 100 includes a reel 10 , two tensioning elements 30 , a fixing sleeve 50 , a pushing element 70 and a locking element 90 .

[0015] Please also see image 3 , the reel 10 includes a socket portion 11 , a threaded portion 13 and an abutting portion 15 respectively disposed at two ends of the socket portion 11 . The sleeve portion 11 is approximately cylindrical, and the threaded portion 13 is formed by extending from one end of the sleeve portion 11 , which is approximately stepped cylindrical and coaxial with the sleeve portion 11 . The abutting porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com