Motor stator-rotor co-assembly device and method

A stator-rotor and stator technology is applied in the field of motor stator-rotor assembling devices, which can solve the problems of long matching length between the motor end cover and the stator mouth, low position accuracy of the manually hoisted rotor, damage to stator windings and bearings, etc. Manual work intensity, high versatility and practicability, and the effect of interference fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

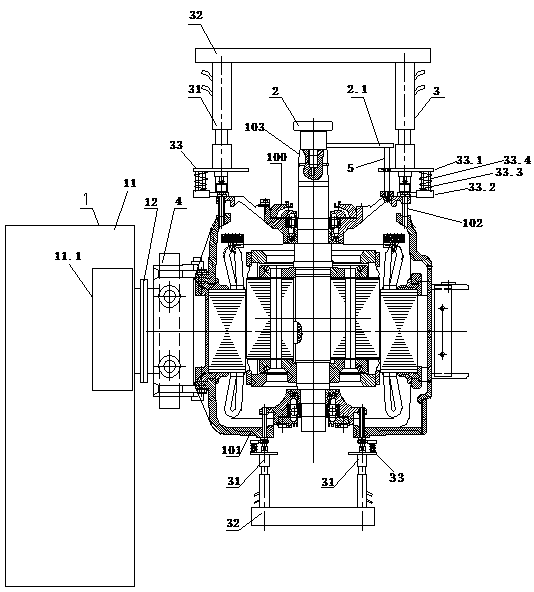

[0028] Combine below figure 1 Embodiments of the present invention are described in detail.

[0029] The motor stator and rotor assembly device is characterized in that it includes a stator displacement device 1 for driving the stator to rotate to change the axial orientation of the stator, a grabbing hanger 2 for hoisting the rotor, and a rotor end cover 100 and stator frame for automatically tightening The bolt automatic tightening device 3 of the connecting bolt 102 between 101, the stator displacement device 1 is connected with the stator base 101, the grabbing hanger 2 is connected with the rotor shaft extension end 103, the bolt automatic tightening device 3 is connected with the connecting bolt 102, The rotor is loaded into the stator as the connecting bolts 102 are tightened, and the rotor end cover 100 is interference fit with the stator frame 101 as the connecting bolts 102 are tightened.

[0030] In the motor stator-rotor assembly device as shown in the figure, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com