Installation mechanism for handle material guide pipe of fire extinguisher

A technology of installation mechanism and material guide tube, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low production efficiency, achieve the effect of simple structure, convenient use, and reduce the labor workload of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

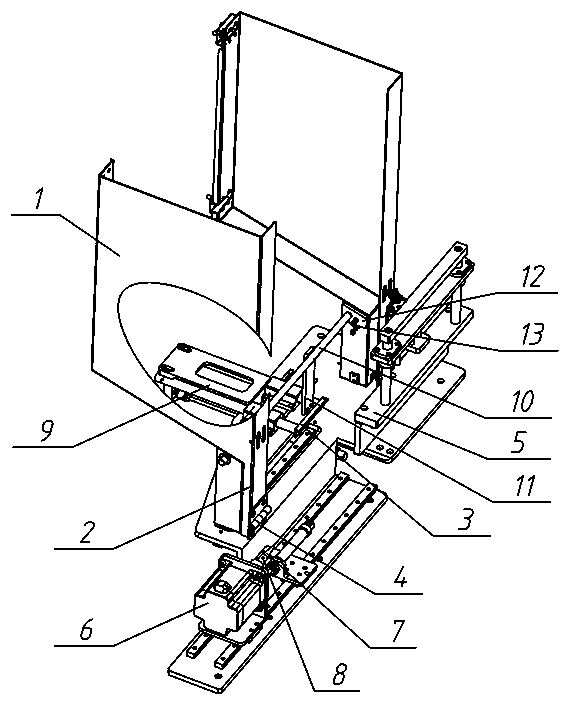

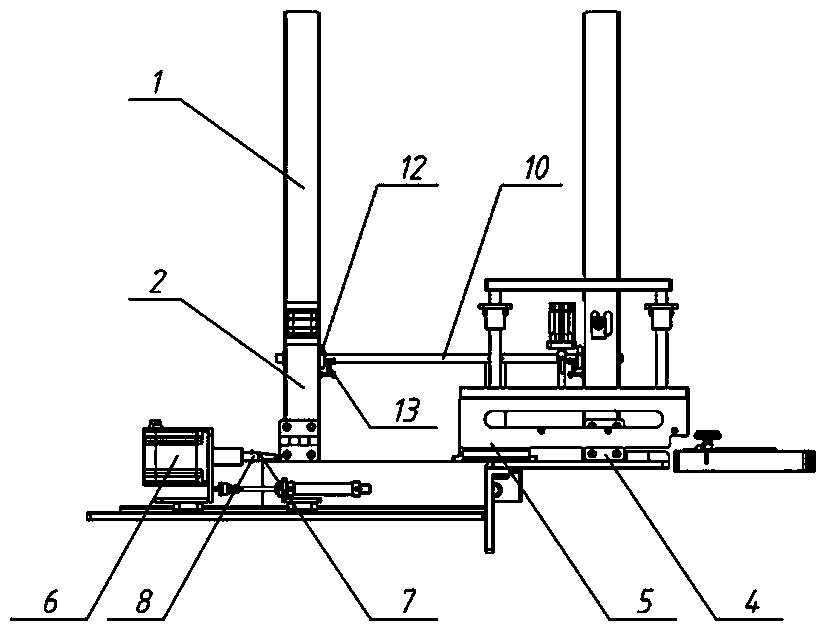

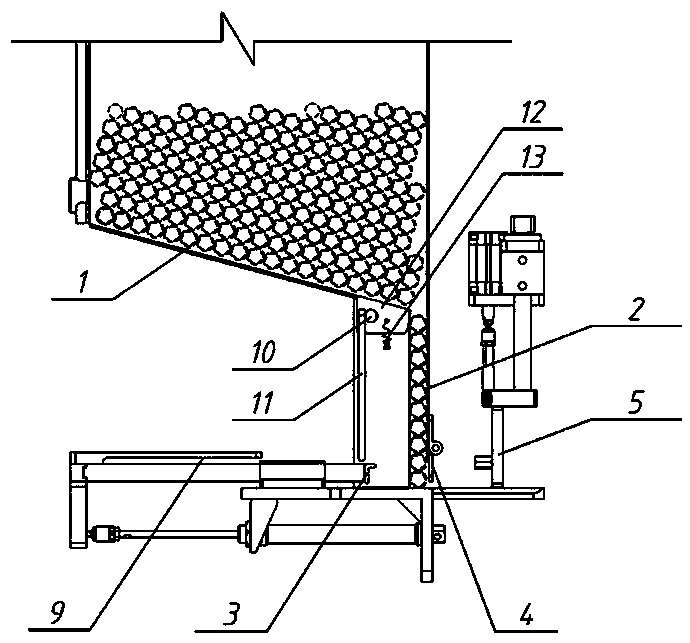

[0013] Such as Figure 1-3 As shown, the fire extinguisher handle guide pipe installation mechanism of the present invention includes a workbench provided with a silo, and the silo includes a storage tank 1 with a slope structure at the bottom and a single unit vertically connected at the lowest point of the slope. Pipe guide trough 2, the rear side of single-tube feed trough 2 is provided with a pusher plate 3 driven by a horizontal cylinder that is in direct contact with the feed pipe, and the bottom of the front panel of single-tube feed trough 2 is hinged with a single-tube feed baffle 4 , the front side of the single-tube feeding baffle 4 is provided with a vertical cylinder-driven lift-type limiting plate 5 at intervals, and the workbench between the lifting-type limiting plate 5 and the single-tube feeding baffle 4 forms a tube twisting area. In order to facilitate the positioning of the material guide tube, an inverted L-shaped push head is provided at the front of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com