Special terminal actuator for industrial robot for grabbing and screwing steel-drum large-thread cover

A technology of end effectors and industrial robots, applied in robots and other fields, can solve high-demand problems, achieve the effects of improving production efficiency, increasing automation, and improving screwing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

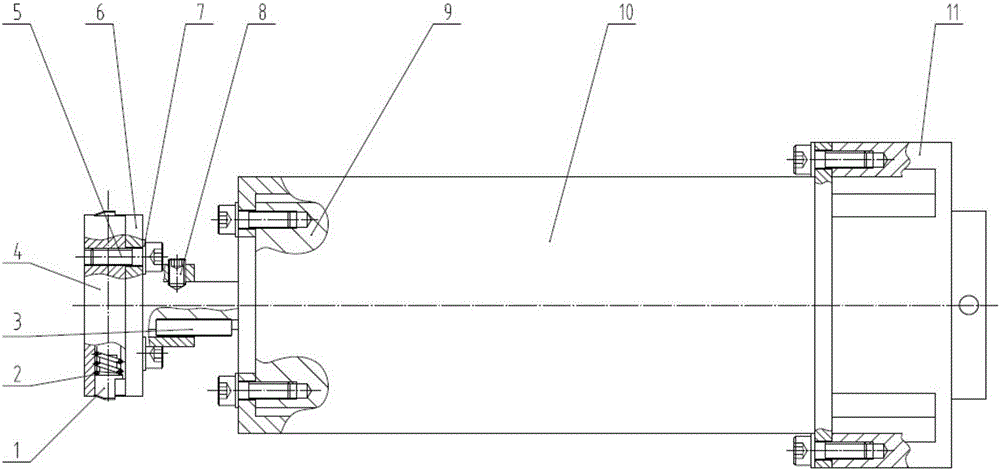

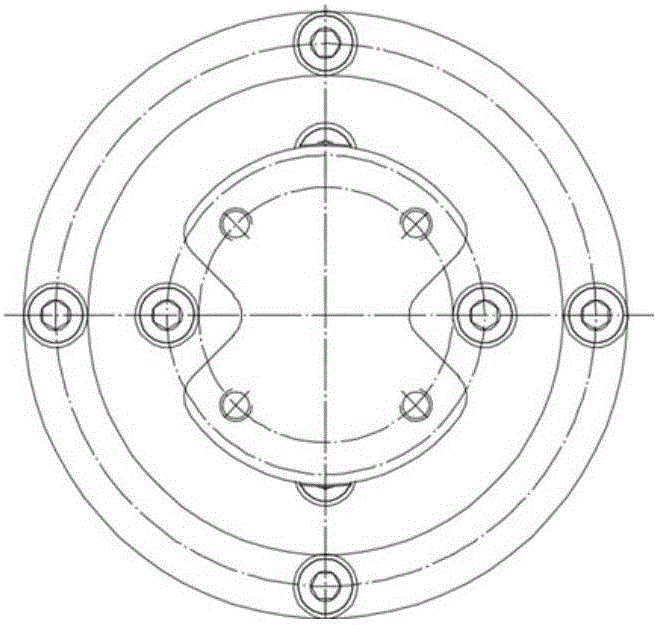

[0014] The specific application process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] When the end effector touches the large threaded cap of the steel drum, the wedge-shaped pusher 1 of the actuator is pressed inward, thereby compressing the spring 2, so that the spring 2 generates elastic force; then the wedge-shaped pusher 1 of the actuator exerts pressure on the inner wall of the large threaded cap, When the actuator is fully inserted into the large threaded cap of the steel drum, the actuator stops moving downwards and turns to extract the threaded cap upwards. The wedge-shaped pusher 1 of the actuator generates static friction with the inner wall of the threaded cap. Through corresponding calculations, it can be obtained that the actuator When the material of the wedge-shaped pusher 1 is nylon 66, the maximum static friction force with the inner wall of the large threaded cap of the steel drum is greater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com