Automatic material storing and taking device

An automatic access and material technology, applied in the direction of storage devices, transportation and packaging, etc., can solve the problems of effective use of unresolved space, occupying a large warehouse area, and low storage density, so as to reduce management costs and the cost of related supporting facilities , Large storage space and large storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

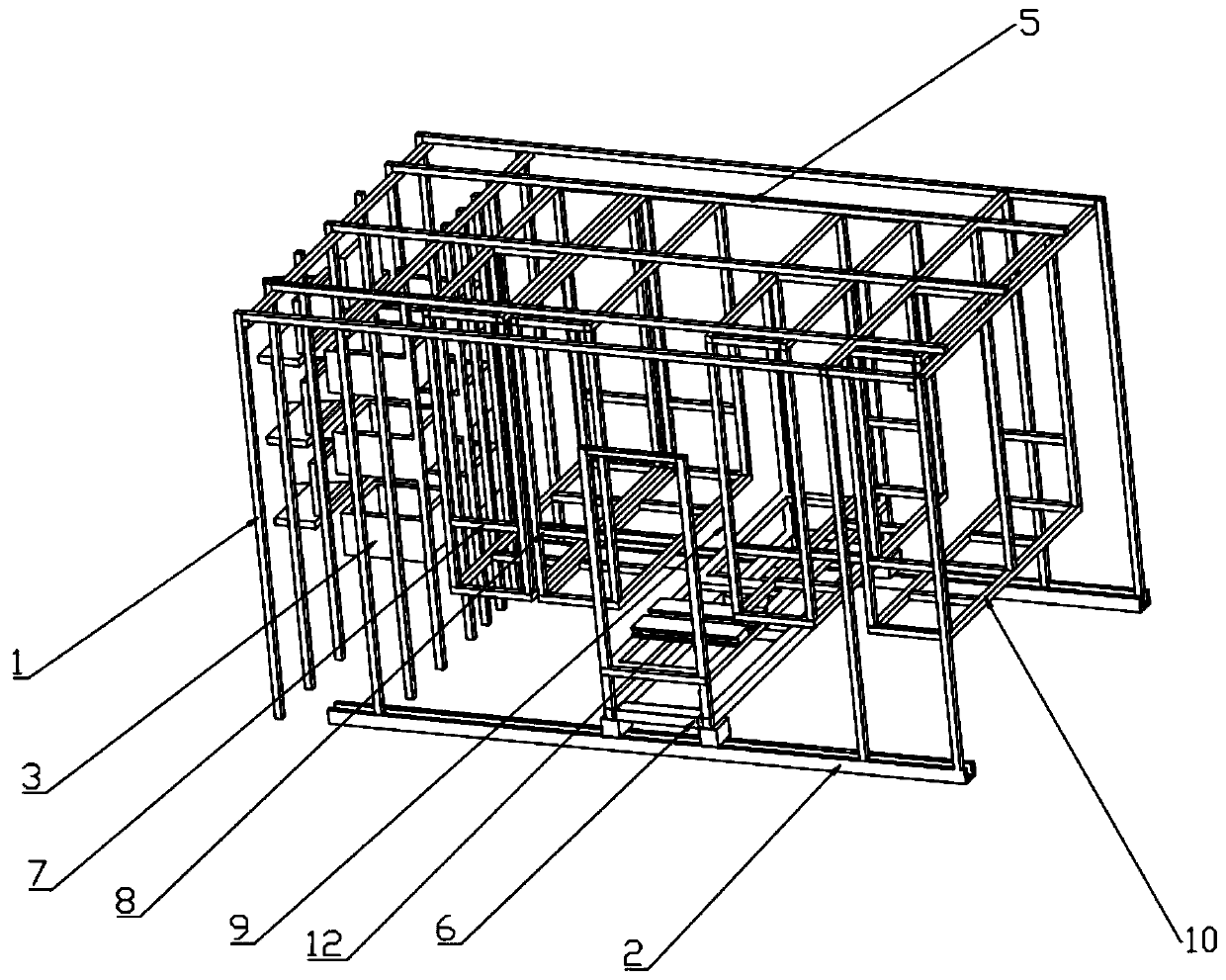

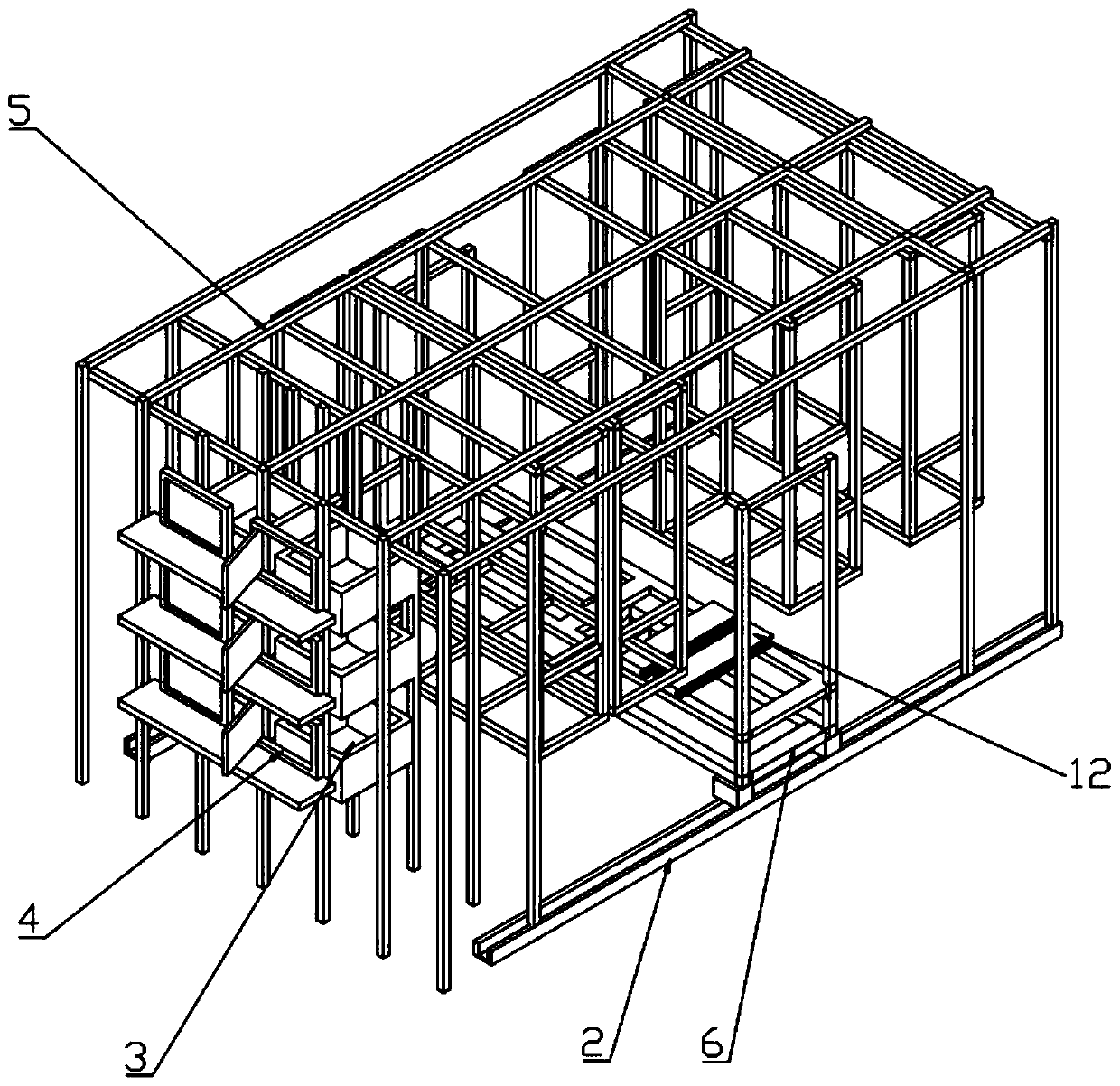

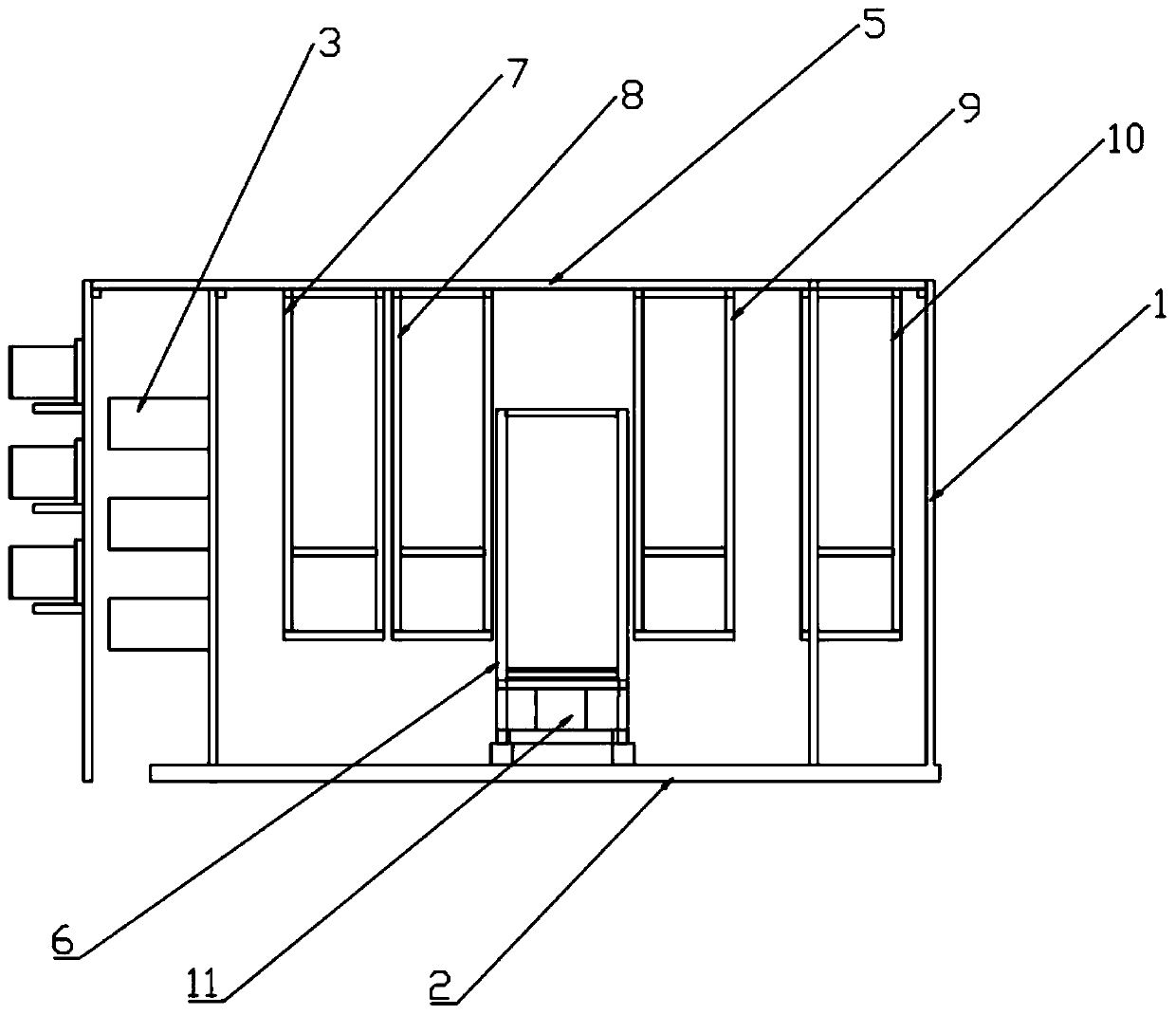

[0020] In conjunction with the accompanying drawings, an automatic material access device includes an external frame structure 1, a track part 2, a material box 3, a material retrieval port 4, a sky rail part 5 arranged on the exterior frame structure 1, and a sky rail part 5 The shelf part on the top, the stacker truck 6 on the track part 2, the shelf part includes the first shelf 7, the second shelf 8, the third shelf 9 and the fourth shelf 10, the first shelf 7 and the second shelf The two shelves 8 are all slidably connected with the sky rail parts 5, and the first shelf 7 and the second shelf 8 slide along the length direction of the first shelf 7, and the third shelf 9 and the fourth shelf 10 are all connected to the sky rail. The components 5 are fixedly connected, the track part 2 is located at the end corresponding to the track part 2 on the outer fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com