Novel high-performance industrial glue powder and preparation method thereof

A high-performance, industrial technology, applied in the direction of adhesive types, starch-derived adhesives, polymer adhesive additives, etc. application and other issues, to achieve long shelf life, easy operation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

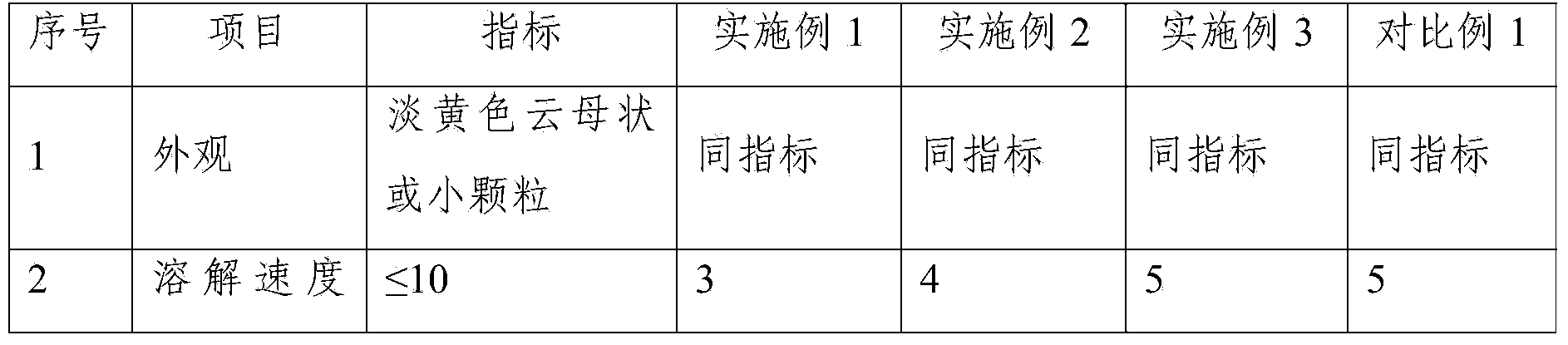

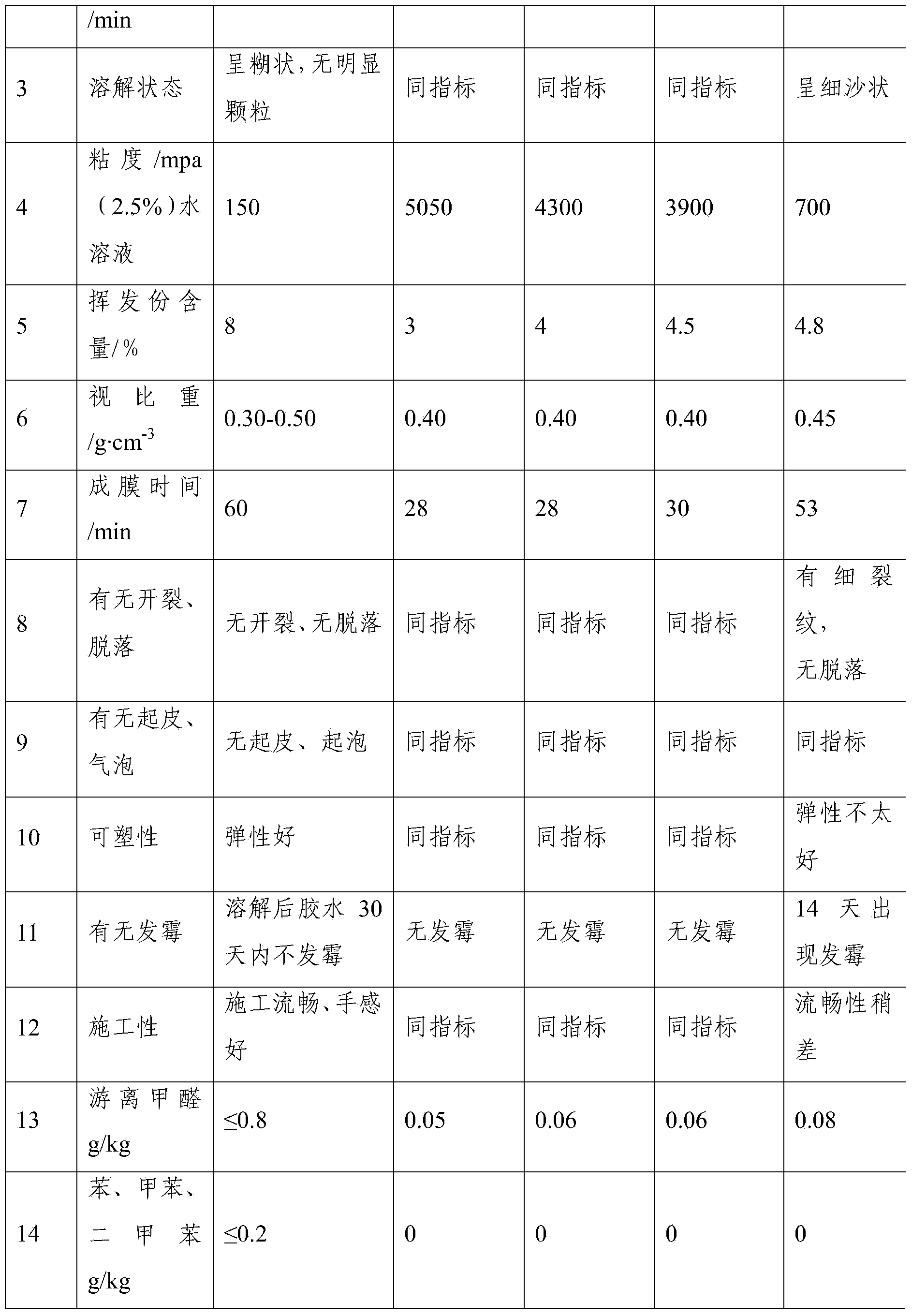

Examples

Embodiment 1

[0026] A novel high-performance industrial rubber powder is prepared according to the following steps:

[0027] A. Mix 100kg of cornstarch with 7.5kg of catalytic aid (anhydrous sodium sulfate and sodium hypochlorite in a weight ratio of 1:2), add 120kg of water to adjust and form a starch milk solution with a mass concentration of about 45%, and add 15% of the mass concentration Sodium hydroxide solution 20kg, gelatinize and alkalinize the starch milk, and keep it for 30 minutes;

[0028] B, starch paste after activation is mixed with 17.5kg ethanol solution to form a uniform mixture, and under the situation of keeping stirring, add 32.5kg of etherification agent (3-chloro-2-hydroxypropyl trimethyl ammonium chloride and Chloroacetic acid is composed of 1:180 by weight), and the temperature is controlled at 30-35°C for 30 minutes;

[0029] C. Add 22.5kg of esterification agent (triethyl phosphate) dropwise to the reaction system, keep the temperature at 50-60° C., add the tim...

Embodiment 2

[0032] A novel high-performance industrial rubber powder is prepared according to the following steps:

[0033] A. Mix 100kg of potato starch with 5kg of catalytic aid (anhydrous sodium sulfate and sodium hypochlorite in a weight ratio of 1:3), add 110kg of water to adjust and form a starch milk solution with a mass concentration of about 47%, and add hydrogen with a mass concentration of 15% Sodium oxide solution 25kg, starch milk gelatinization and alkalization, and keep for 30 minutes;

[0034] B. The starch paste after activation is mixed with 17.5kg ethanol solution to form a uniform mixture. While keeping stirring, add 29kg of etherification agent (3-chloro-2-hydroxypropyltrimethylammonium chloride and chlorine Acetic acid is composed of 1:200 by weight), and the temperature is controlled at 30-35° C. for 30 minutes;

[0035] C. Add 25.5 kg of esterifying agent (being triethyl phosphate) dropwise to the reaction system, keep the temperature at 50-60° C., and add the tim...

Embodiment 3

[0038] A novel high-performance industrial rubber powder is prepared according to the following steps:

[0039] A. Mix 100kg of tapioca starch with 5kg of catalytic aid (anhydrous sodium sulfate and sodium hypochlorite in a weight ratio of 1:3), add 110kg of water to adjust and form a starch milk solution with a mass concentration of about 47%, and add hydrogen with a mass concentration of 15% Sodium oxide solution 25kg, starch milk gelatinization and alkalization, and keep for 30 minutes;

[0040] B. The starch paste after activation is mixed with 17.5kg ethanol solution to form a uniform mixture. While keeping stirring, add 29kg of etherification agent (3-chloro-2-hydroxypropyltrimethylammonium chloride and chlorine Acetic acid is composed of 1:200 by weight), and the temperature is controlled at 30-35° C. for 30 minutes;

[0041] C. Add 25.5kg of esterifying agent (composed of triethyl phosphate and ethyl acetate in a weight ratio of 1:0.05) dropwise to the reaction system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com