Fully-automatic typewriter

A fully automatic, workpiece technology, applied in printing, stamping and other directions, can solve the problems of low typing efficiency, prone to industrial injuries, high production costs, and achieve the effects of high processing quality, low labor intensity and low defect rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

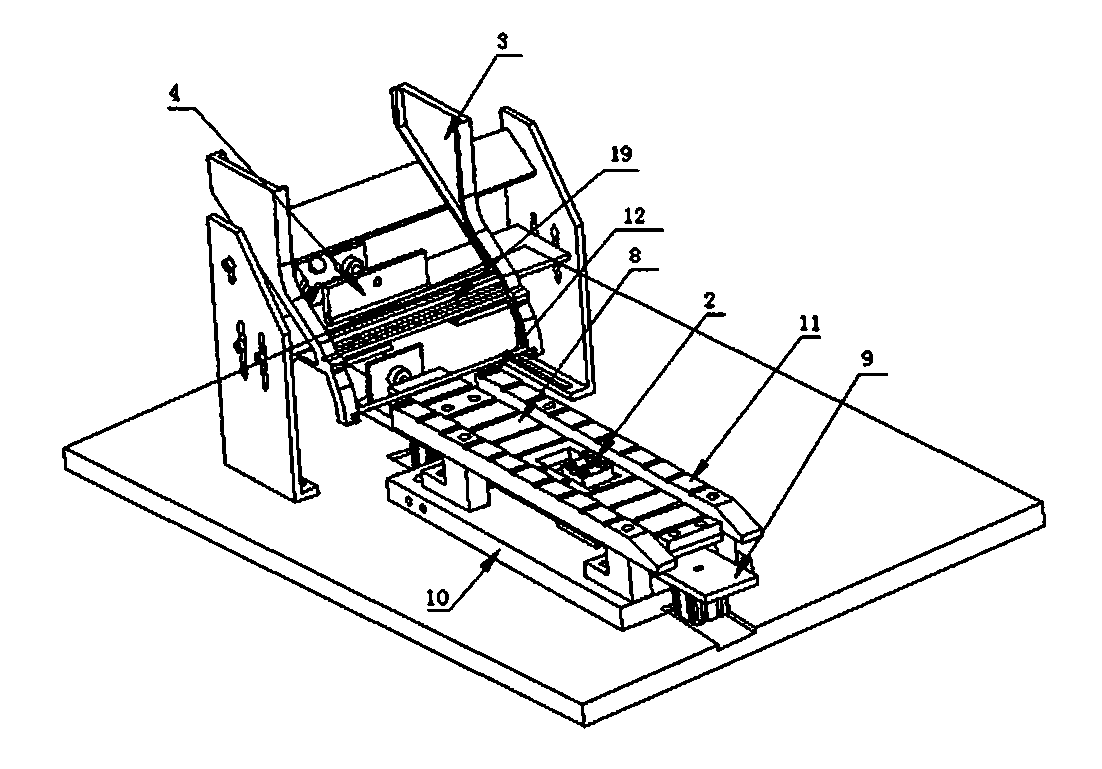

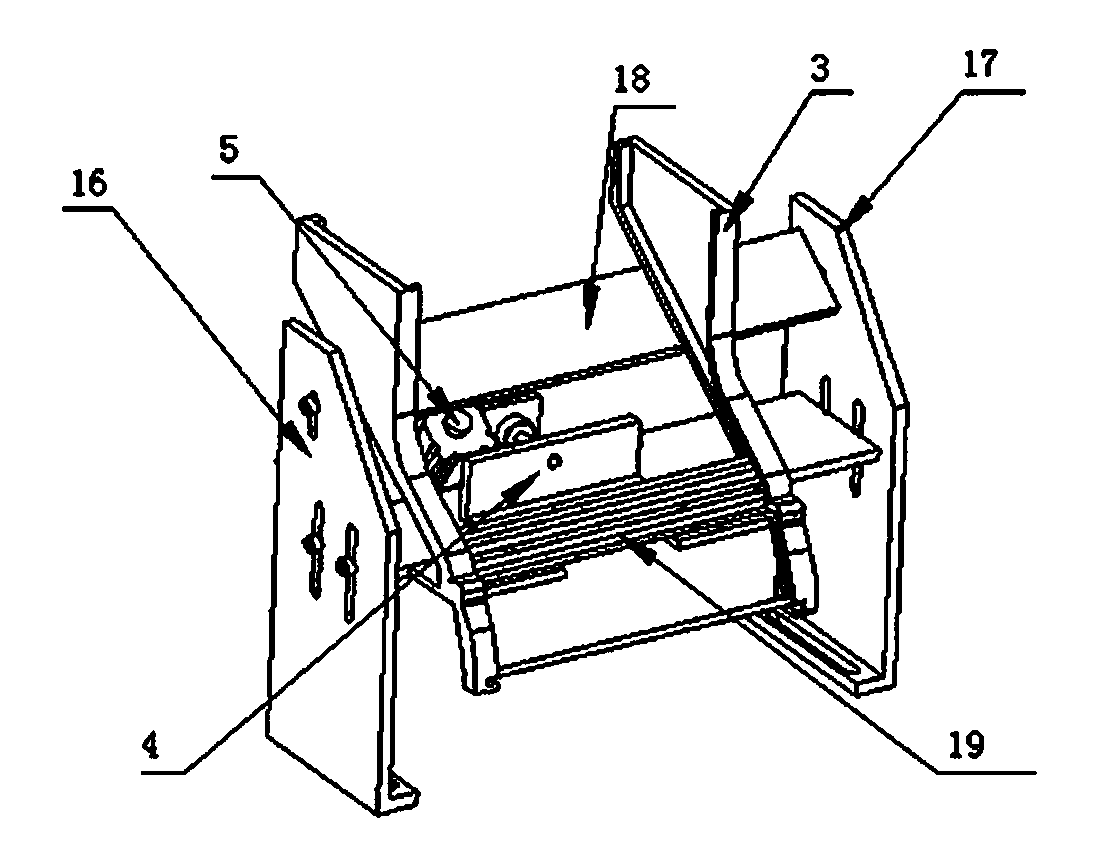

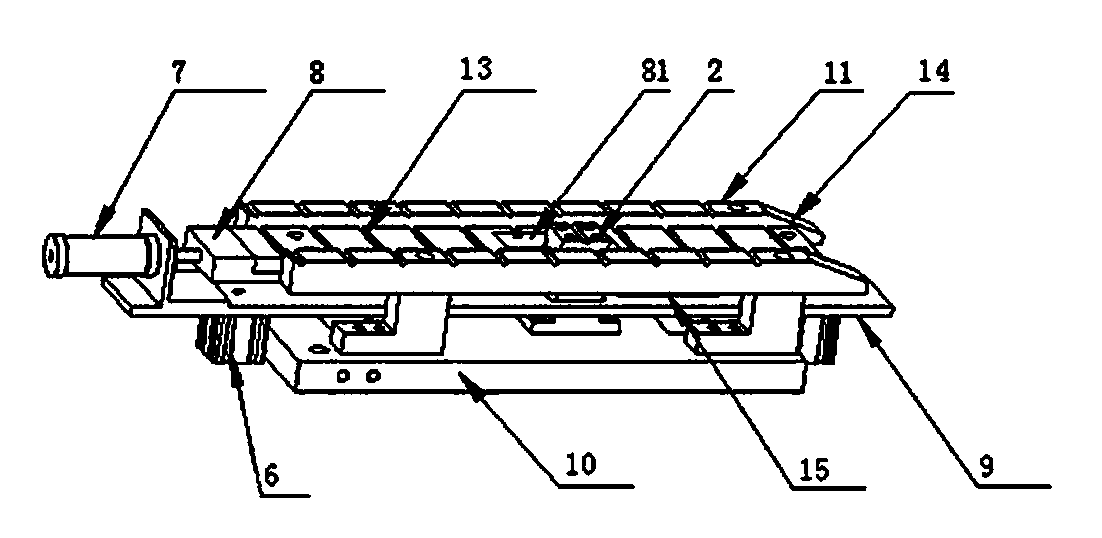

[0023] Embodiment: a kind of fully automatic typewriter, comprises discharging device, conveying device, typing mold and controller, described typing mold comprises upper mold 1 and lower mold 2, and lower mold 2 stops, and upper mold 1 longitudinally can move and be positioned at Right above the lower die 2, the lower die 2 is provided with a workpiece positioning device, the lower end of the upper die 1 is provided with a punch, and the discharge device can arrange the workpieces in sequence and output them to the conveying device in sequence, and the conveying device can make the workpieces Sequentially transported to the positioning device of the lower mold 2 of the typing mold to stay for a set time and output the typing mold, the controller controls the action of the discharge device, the conveying device and the typing mold, and puts the workpiece 19 to be typed into the discharge device. The discharge device automatically arranges the workpieces in order and outputs the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com