Valve body and bonnet connection torsion dispensing assembly machine

A torque point, valve body technology, applied in the direction of assembly machines, connecting components, devices for coating liquid on the surface, etc. Uniformity and other issues, to achieve the effect of high connection firmness, saving processing time, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

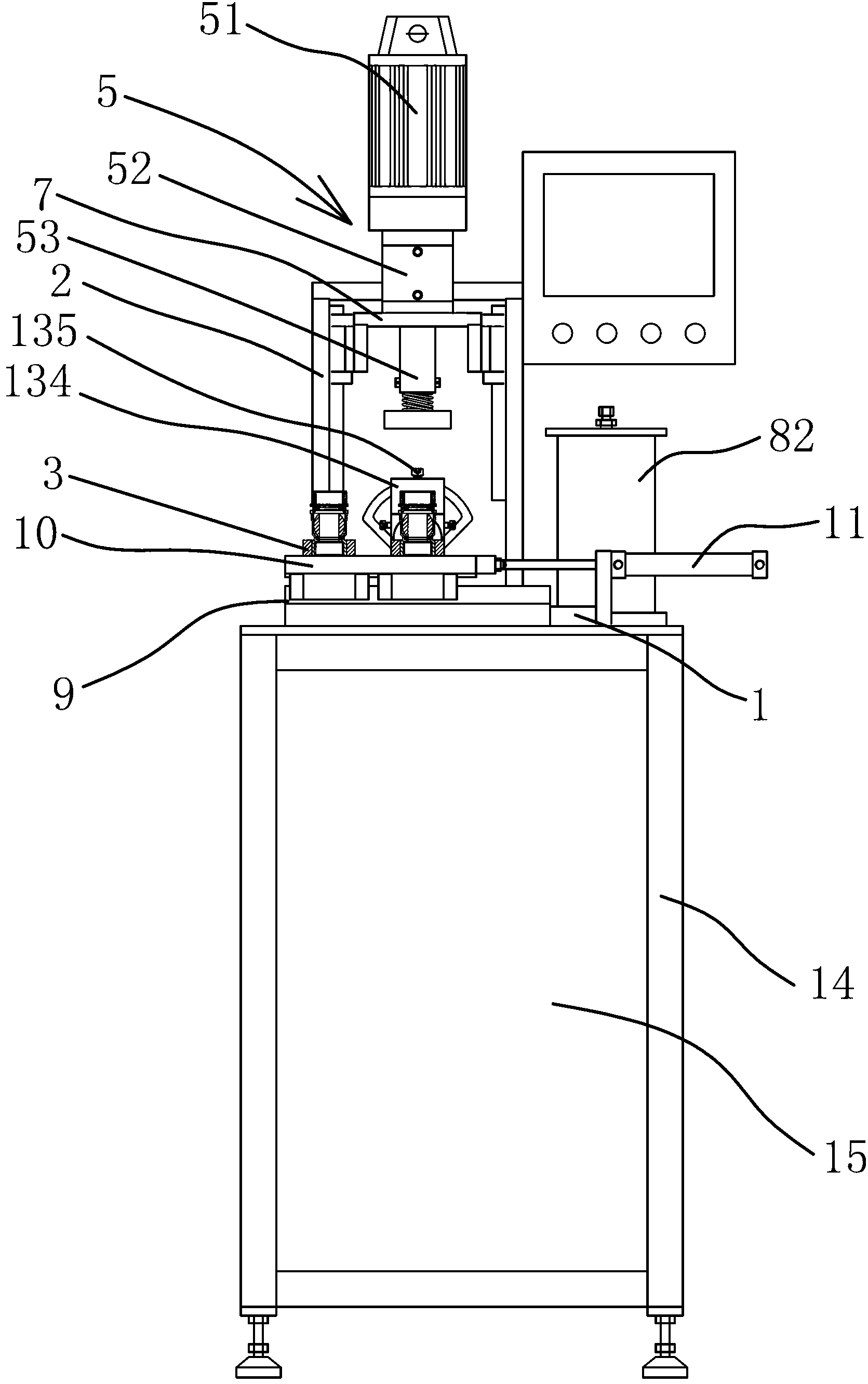

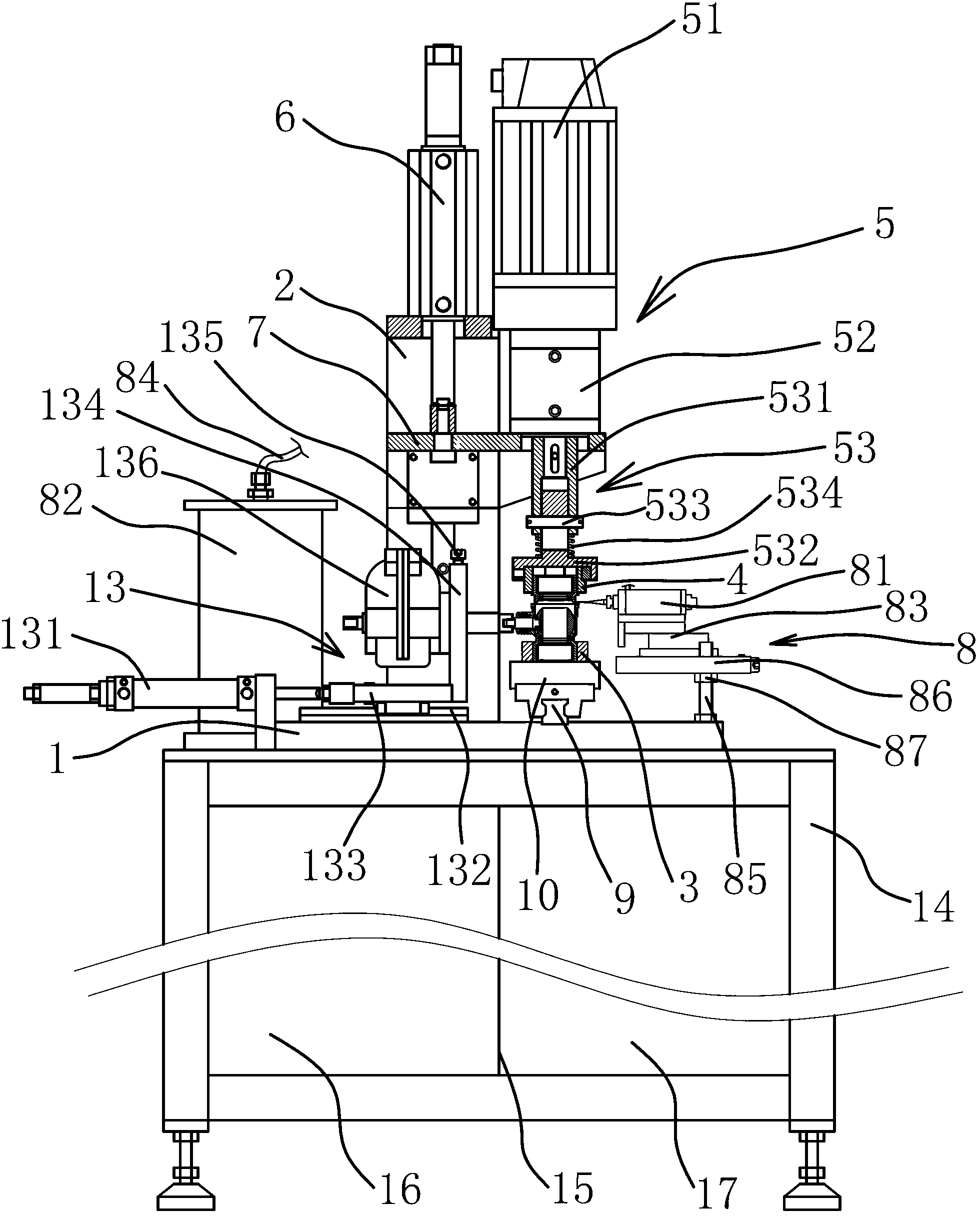

[0032] This assembly machine is mainly used to connect the valve body and bonnet of the valve, such as figure 1 , figure 2 As shown, it includes workbench 1, bracket 2, upper mold body 4, lower mold body 3, lifting cylinder 6, lifting slide table 7, torque control mechanism 5, glue dispensing mechanism 8, valve stem rotation mechanism 13, frame 14 and chassis 15.

[0033] There is a cabinet 15 in the frame 14, one side of the cabinet 15 is an air control cabinet 16, and the other side is an electric control cabinet 17, and the top of the frame 14 is horizontally fixed with a workbench 1. The two sides of the workbench 1 are symmetrically fixed with vertical boards respectively, the tops of the two vertical boards are connected by a horizontal board to form a support 2, and a lifting cylinder 6 is installed upside down above the horizontal board, and the piston rod of the lifting cylinder 6 passes through the horizontal board , the end place of piston rod is fixedly connecte...

Embodiment 2

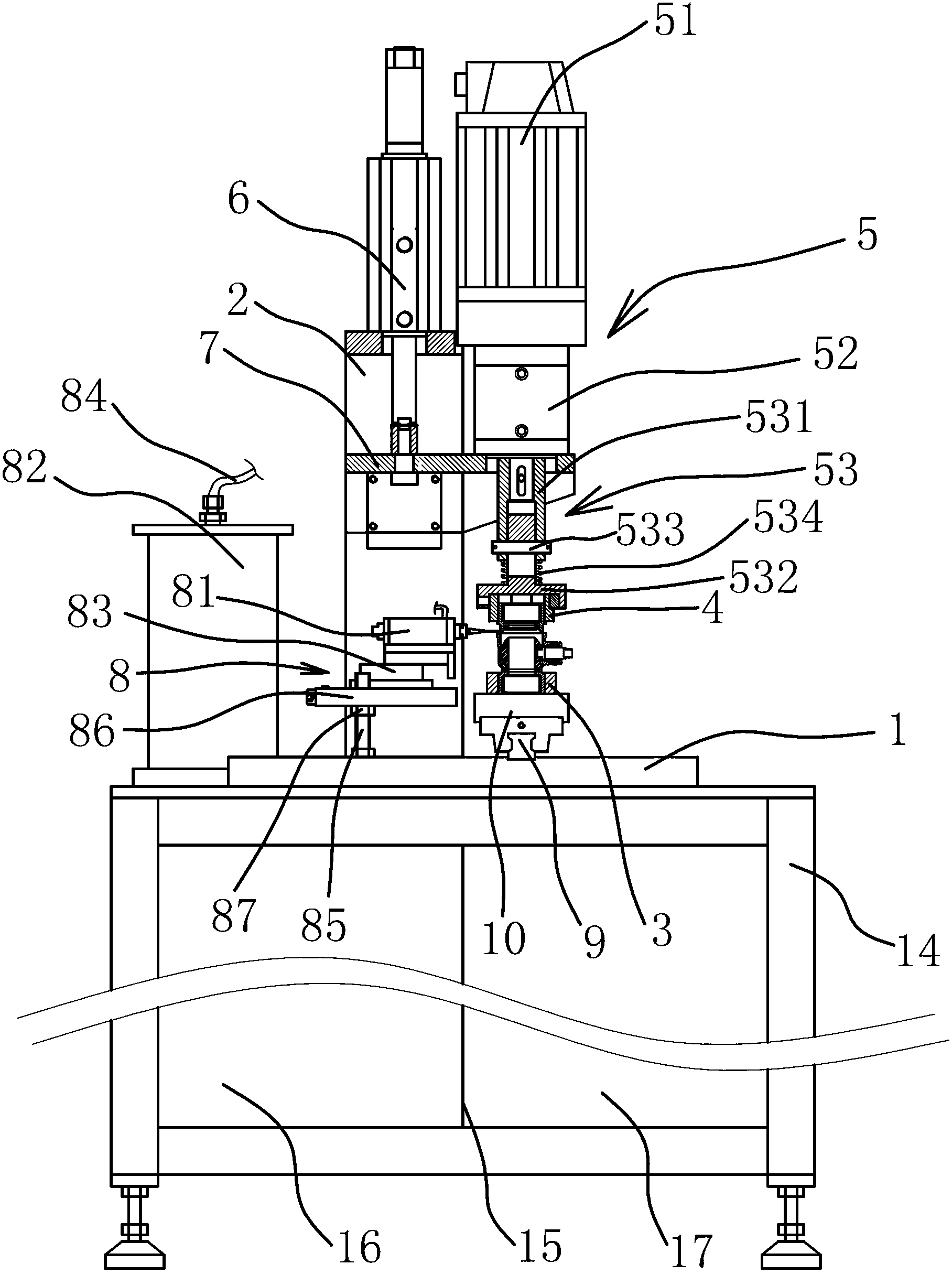

[0040] Such as image 3 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that this assembly machine does not have a valve stem rotation mechanism, and the injection valve, slide cylinder, adjustment rod, adjustment block and nut are located Embodiment A valve stem rotation mechanism is located on the other side of the lower die body operator. This structure makes the operation convenient for the operator when loading and unloading materials.

Embodiment 3

[0042] Such as Figure 4 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the lower die body 3 is fixed on the turntable 12, and the center of the turntable 12 is connected with the power mechanism. The motive mechanism is a rotary cylinder. In actual production, the power mechanism can be a combination of a stepping motor and a reducer, or a combination of a motor and a divider. In this embodiment, the number of lower mold bodies 3 is 4. The circumferential direction is equidistantly arranged, and the slide table cylinder 83 is fixed on the non-rotating axis position of the turntable 12, and the rotating cylinder drives the turntable to rotate so that the lower die body 3 is located directly below the upper die body 4 in turn to realize the processing of the valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com