End face run-out and bolt detection integrated machine for third generation hub unit

A technology of end face beating and hub unit, applied in the field of automatic testing equipment, can solve the problems of high cost of manual testing, low accuracy of testing results, slow testing speed, etc., and achieve the effect of fast testing speed, avoiding work injury and avoiding manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

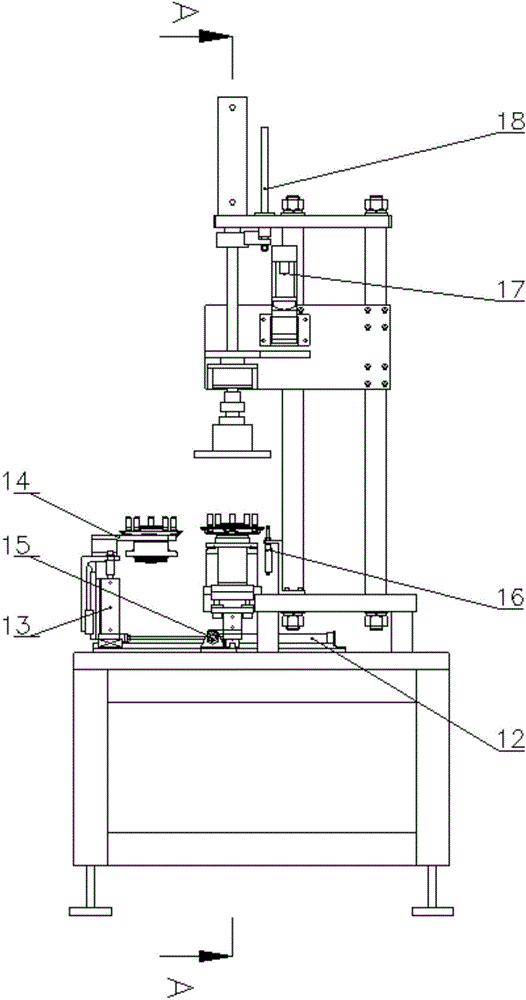

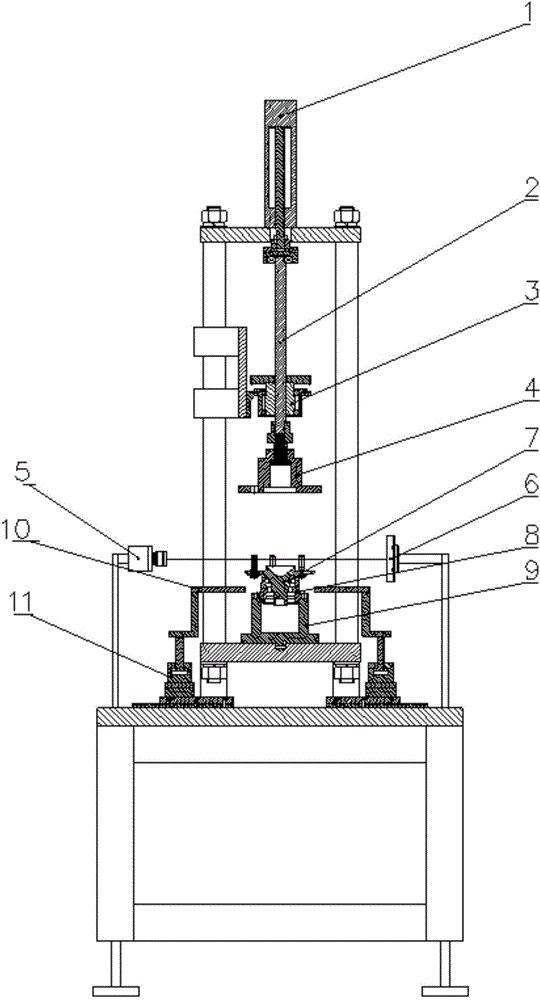

[0024] Embodiment: A third-generation hub unit end face runout and bolt detection integrated machine, including a workbench, a measuring platform 9, a positioning device for the bearing outer ring flange 8, a measuring pen 16, a measuring disc 4, a longitudinal drive device 1, a rotating Drive device 17, light source 6, image acquisition device 5, measurement result output device and controller, wherein:

[0025] The measuring platform 9 capable of positioning and supporting the bearing to be tested is fixed on the workbench. The light source 6 and the image acquisition device 5 are symmetrically distributed on both sides of the measurement platform 9. Imaging and signaling to the controller;

[0026] The bearing outer ring flange 8 positioning device can fix and position the bearing outer ring flange 8 on the measuring platform 9;

[0027] The measuring disc 4 can be raised and lowered longitudinally and rotated in the circumferential direction. It is positioned directly abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com