Full-automatic aluminum rod heating furnace

A fully automatic heating furnace technology, applied in the field of aluminum bar heating furnace, can solve the problems of work injury and inconvenient transportation of aluminum bars, and achieve the effect of saving labor, avoiding work injury and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

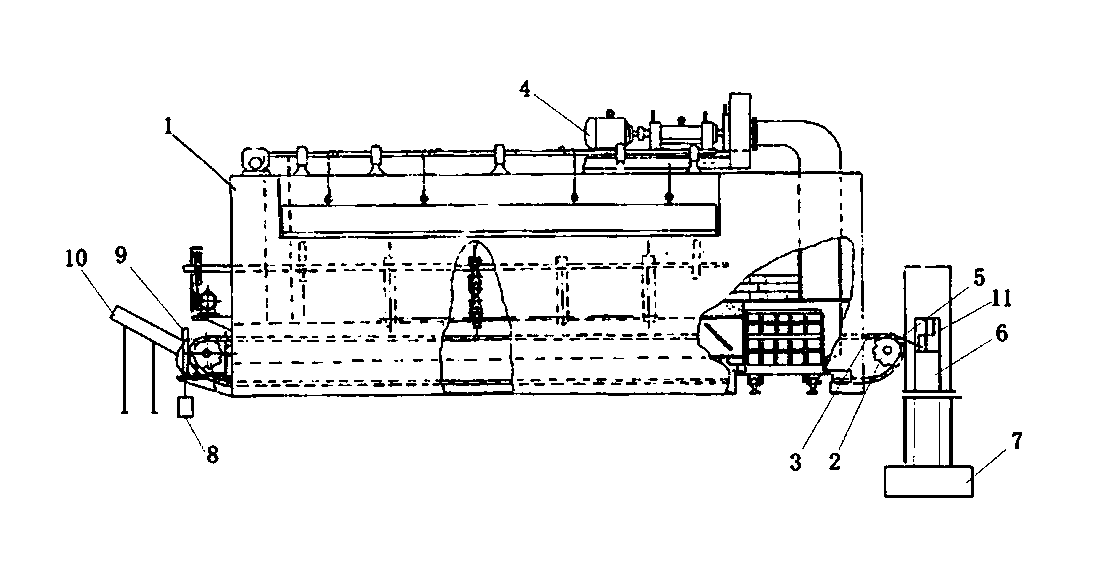

[0013] Embodiment: a fully automatic aluminum rod heating furnace, including a furnace body 1, a heating circulation system, a feeding mechanism, 2 sprocket frames, a sprocket 2, a chain 3 and a driving device, and a furnace is provided in the furnace body 1, and the There is an insulation layer on the outside of the furnace, and the inlet of the furnace is connected to the feeding mechanism. Two sprocket frames are fixed on both ends of the furnace body 1. The sprocket 2 frame can be rotated. The sprocket 2 is set on the sprocket 2. 3. The chain 3 runs through the furnace, and the driving device drives the sprocket 2 to rotate. The heating cycle system includes a burner and a suction fan 4. The air outlet of the suction fan 4 communicates with the furnace, and the furnace is equipped with a The smoke exhaust chimney connected to the outside world is also provided with a discharge bracket and a controller. The discharge bracket is provided with an inclined connecting plate 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com