Safety device of punch

A technology of safety devices and punching machines, which is applied in safety equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as high risk, inability to use mechanical punching machines, and inability to speed up operation, so as to achieve the effect of increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

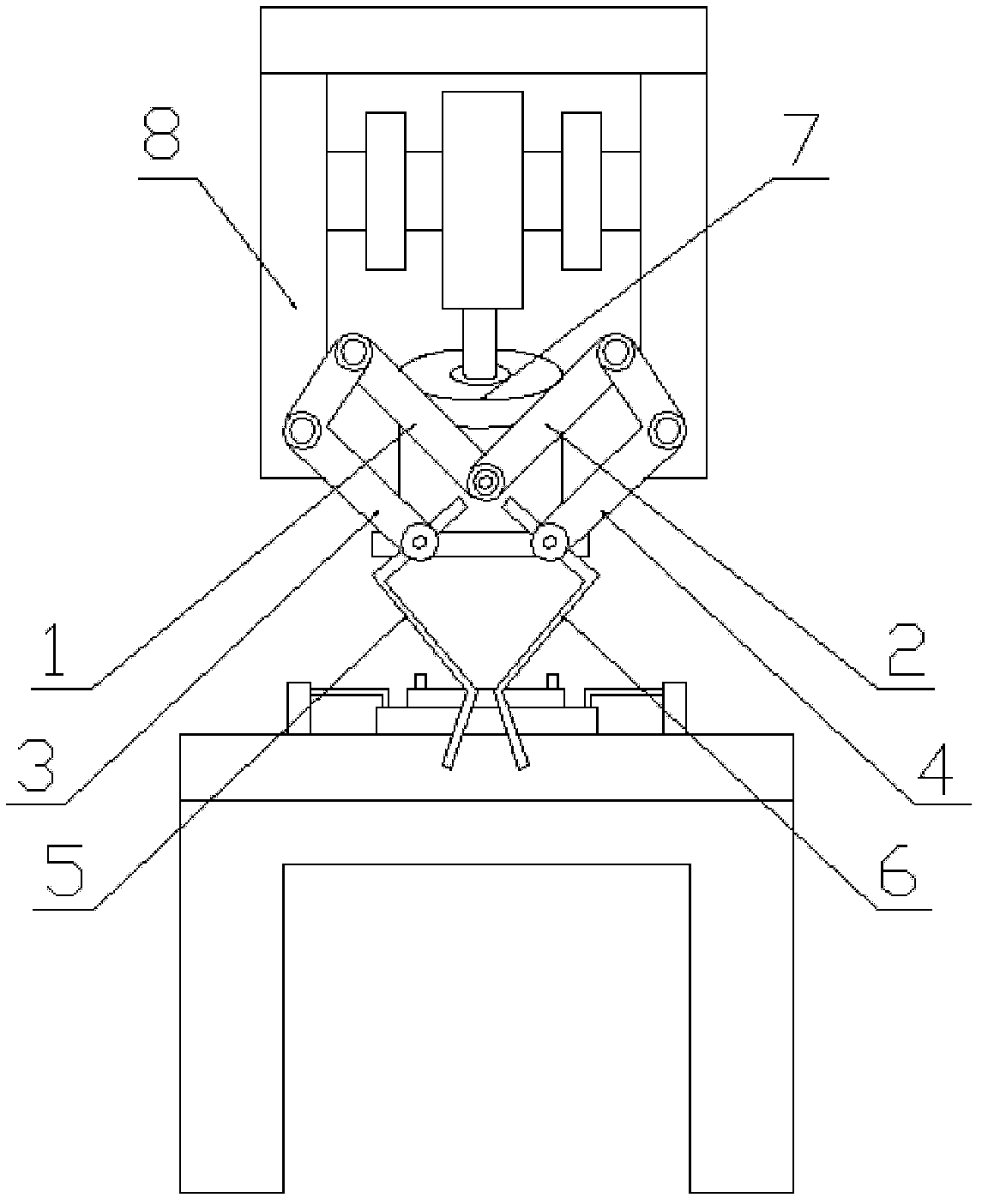

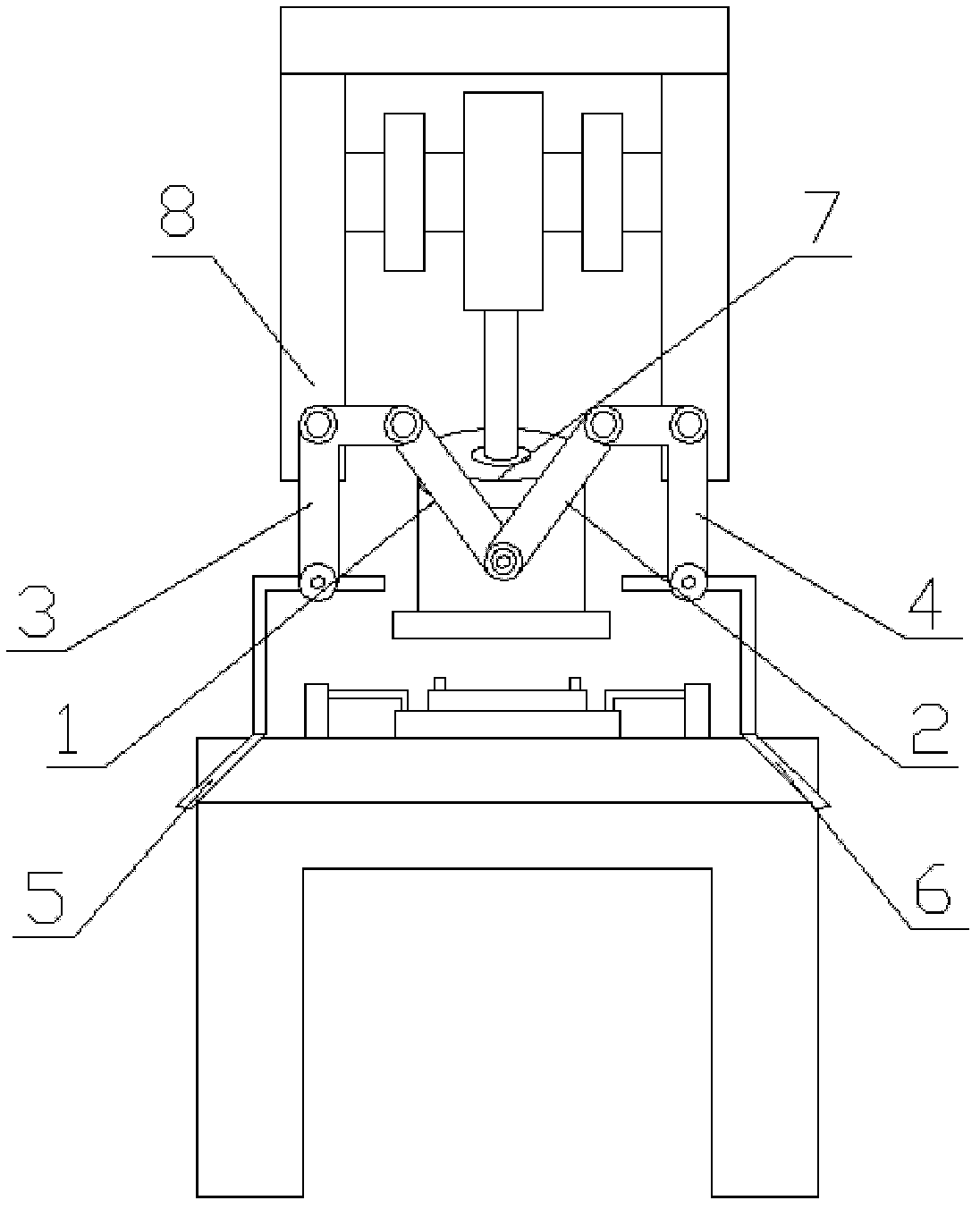

[0013] Embodiment: a safety device for a punching machine, comprising the first, second, third, and fourth connecting rods 1, 2, 3, 4 and the first and second driving rods 5, 6, one end of the first and second connecting rods 1, 2 is respectively connected to The hammer 7 of the punch press is pivotally connected, and the corners of the third and fourth connecting rods 3 and 4 of the L-shape are pivotally connected with the bed 8 of the punch press, and the other ends of the first and second connecting rods 1 and 2 are connected to the third and fourth connecting rods respectively. One end of the rods 3 and 4 is movable and hinged, and the other ends of the third and fourth connecting rods 3 and 4 are fixedly connected with one end of the first and second driving rods 5 and 6 respectively, and the other ends of the first and second driving rods 5 and 6 are located near the press console On the operator's side, the worker's operating arm just stops at the opposite ends of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com