Injection molding element large-flow-pass high-precision hot-melting shearing jig

A large flow channel, high-precision technology, applied in the field of large flow channel high-precision hot melt shearing fixture for injection molded parts, can solve the problems of high labor intensity of operators, prone to work accidents, slow shearing speed, etc. Fast speed, low labor intensity, and the effect of avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

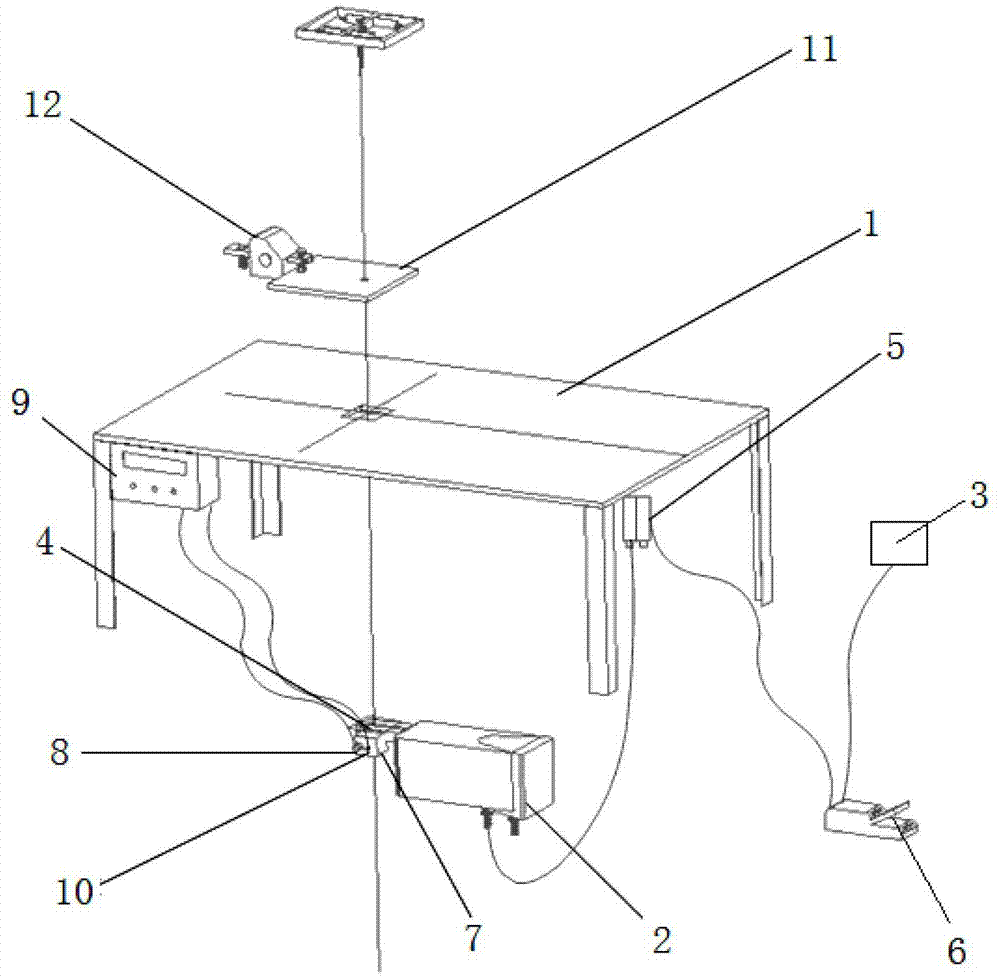

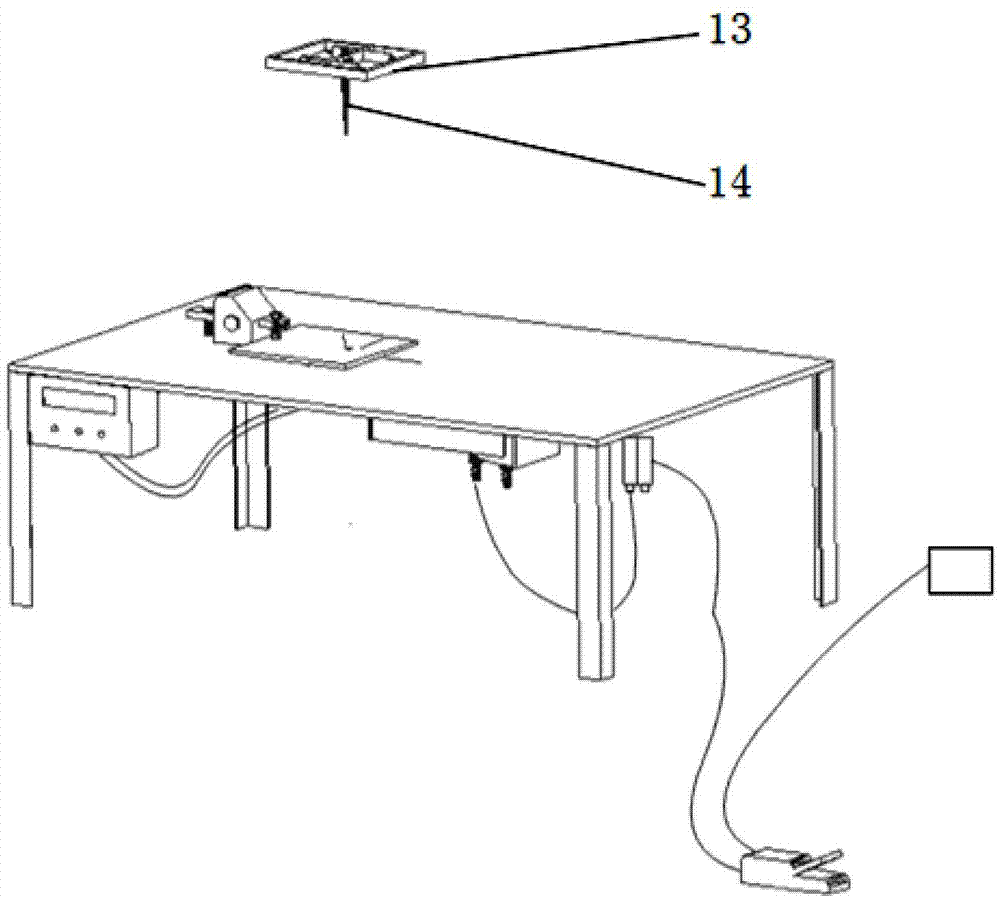

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] like Figure 1-2 As shown in the figure, a high-precision hot melt shearing fixture with a large flow channel for an injection molded part includes a base 1, a gas-heated scissors 2 and a gas source 3, and a rectangular shape for passing through the nozzle 14 of the injection-molded part 13 is opened on the base 1 The opening, the gas-heat scissors 2 are arranged under the base 1, the movable knife 4 at the front end of the gas-heat scissors 2 is located under the rectangular opening, the gas-heat scissors 2 are connected with the air source 3 through the air path, and the gas source 3 is connected to the air source 3. A foot control switch 6 is arranged on the road, which is convenient for the air source 3 to provide air flow to the air heating scissors 2 . A flow regulating valve 5 is arranged between the gas heating scissors 2 and the gas source 3 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com