Full-automatic microwave pretreatment device

A microwave pre-processing and fully automatic technology, applied in the field of microwave applications, can solve the problems of poor repeatability of processing effect, cumbersome operation, and influence on analysis results, and achieve the effects of improving subsequent detection accuracy, reducing the number of equipment, and simplifying the experimental area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

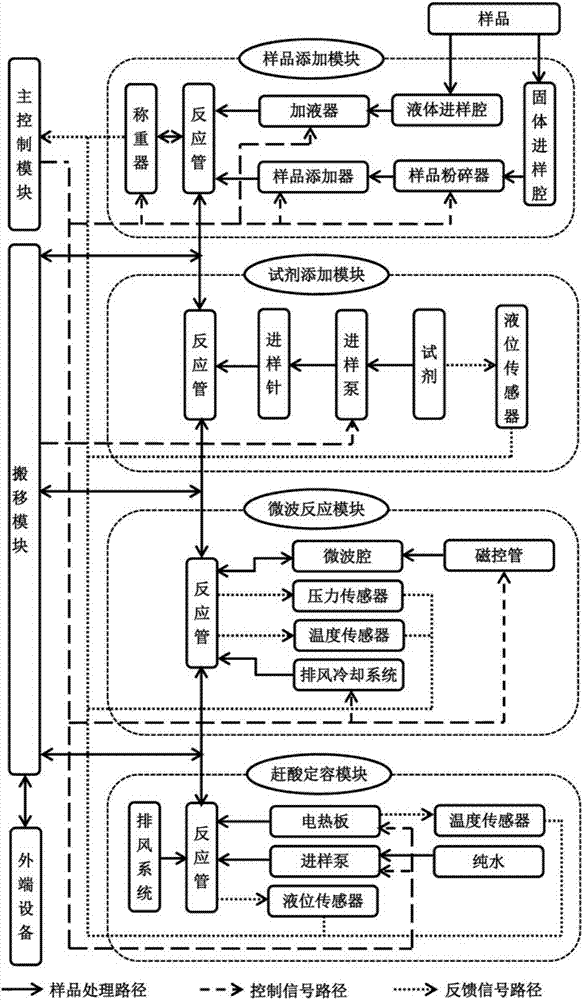

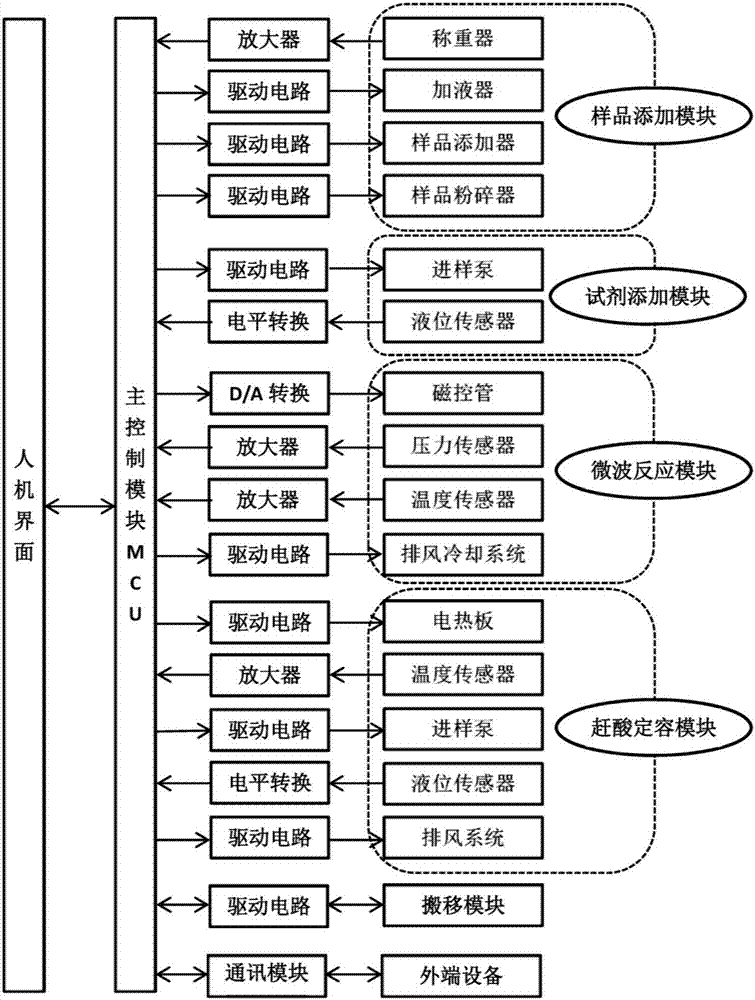

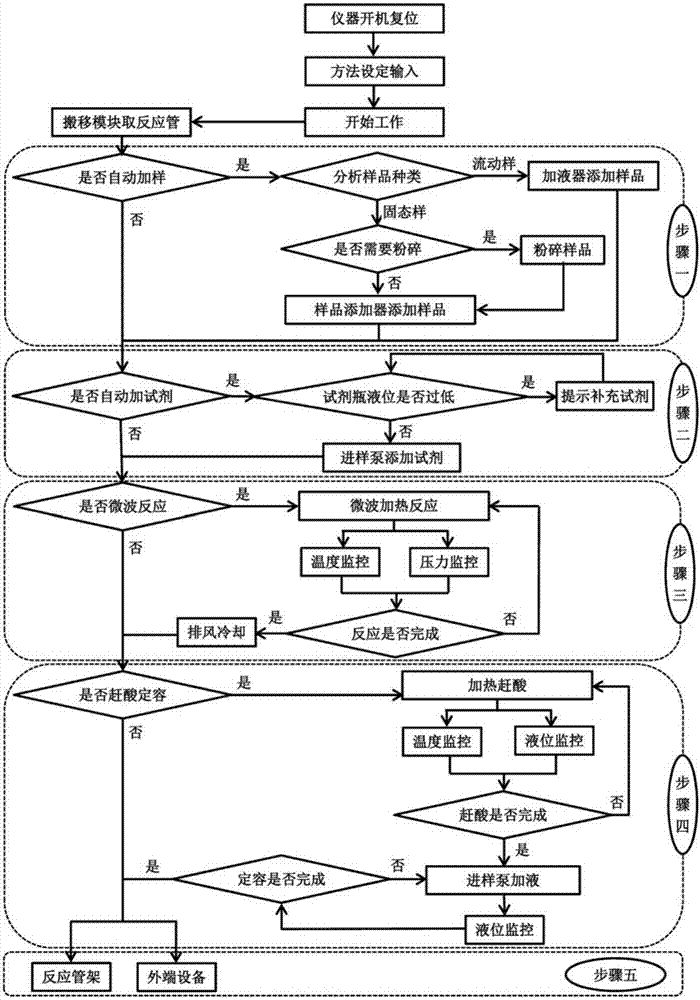

[0078] like figure 1 As shown, the fully automatic microwave pretreatment device of this embodiment includes a sample addition module, a reagent addition module, a microwave reaction module, an acid removal and constant volume module, a mechanical arm for moving the reaction tube between modules, and a module connected to each module respectively. main control module.

[0079] The sample addition module includes a sample injection chamber, an adder, and a weighing device. According to the shape of the sample, the sampling chamber can be a solid sampling chamber or a liquid sampling chamber; the liquid sample enters the liquid sampling chamber and enters the reaction tube through the liquid feeder, and the solid sample enters the solid sampling chamber through the sample pulverizer After crushing, it enters the reaction tube from the sample adder. The reaction tube is connected with the weighing device, and the weighing device feeds back the measurement result of the reaction...

Embodiment 2

[0107] The components of this embodiment are basically the same as those of Embodiment 1, the difference is that the control system further includes a positioning module connected to the mechanical arm, and the positioning module is connected to the main control module of the control system. like Figure 4 As shown, the positioning module is connected with the raw material addition module, the microwave reaction module, the acid and constant volume module and the external equipment; the external equipment refers to atomic absorption spectroscopy (AAS), inductively coupled plasma mass spectrometer (ICP-MS) and Detection equipment such as inductively coupled plasma atomic emission spectrometer (ICP-OES) or cleaning equipment that can clean test tubes, sealing caps and other components.

[0108] According to the precise positioning of the positioning module, the control device controls the moving module to move the reaction container between the raw material adding module, the mi...

Embodiment 3

[0110] When using a detection instrument with relatively strong acid resistance, some samples can be directly loaded for detection without acid removal treatment after digestion. Such users do not need to configure the acid removal and constant volume module. The schematic diagram of the system structure framework in this embodiment is as follows Figure 5 As shown, the electronic control block diagram is shown in Image 6 As shown, the system workflow is as follows Figure 7 As shown, the configuration of other parts is similar to that of Embodiment 1 or Embodiment 2.

[0111]The fully automatic microwave pre-processing device of this embodiment includes a sample adding module, a reagent adding module, a microwave reaction module, a moving module for moving reaction tubes among the modules, and a main control module connected to each module respectively. After the sample and reagent react in the microwave reaction module, the product is directly sent to the external device b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com