Rubber roll winding machine with measuring device

A measuring device and winding machine technology, which is applied in the field of rubber roller winding machines, can solve the problems of inconvenient measurement, unsafety, and inability to automatically detect the thickness of the rubber layer, and achieve the effects of avoiding industrial accidents, simple structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific drawings and embodiments.

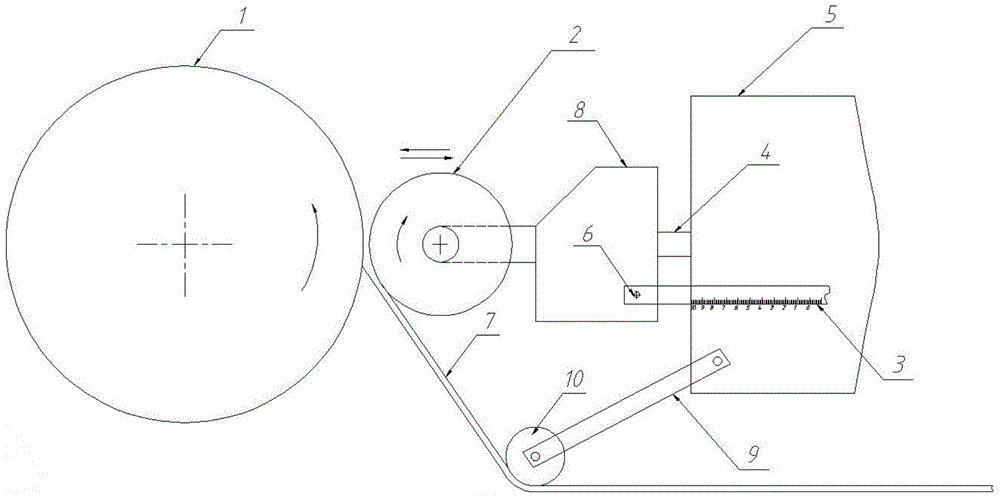

[0015] Such as figure 1 As shown, a rubber roller winding machine with a measuring device includes a body 5, a telescopic rod 4, a bracket 8, a pressure wheel 2, a cantilever 9, and a guide wheel 10; the pressure wheel 2 is fixed on the bracket 8, The support 8 is arranged on one side of the body 5 through the telescopic rod 4; One end is provided with guide wheel 10; It is characterized in that: described support 8 is also provided with a scale 3, and described scale 3 is parallel with described telescoping rod 4; Wherein one end of described scale 3 is fixed on by screw 6 on the bracket 8.

[0016] When using this device, adjust the telescopic rod 4, first make the zero scale line of the scale 3 coincide with the left end face of the body 1; Driven by the telescopic rod 4, the 8 frames move left and right as a whole to form a certain pressure. The pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com