Full-automatic hot press molding and shearing machine for chest cup

A thermoforming and fully automatic technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as low production efficiency, high manufacturing cost, and hardening around the breast cup, so as to improve production efficiency and avoid work-related accidents , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

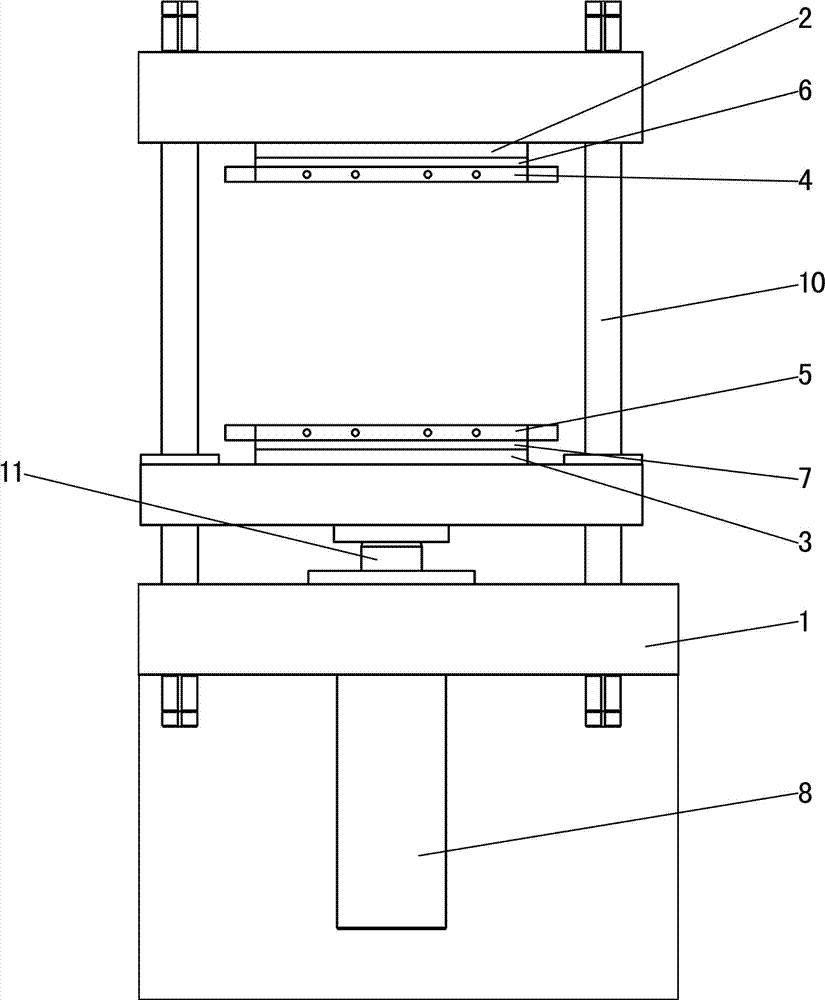

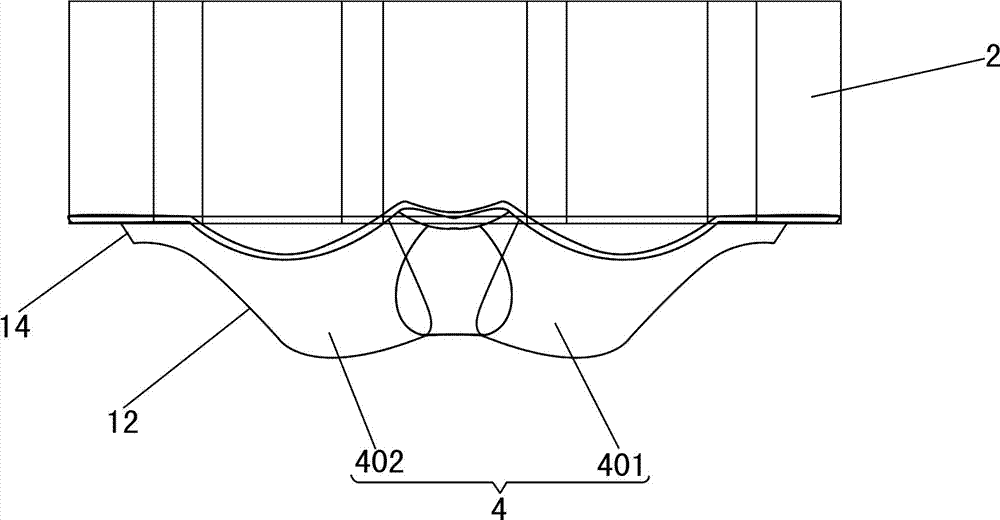

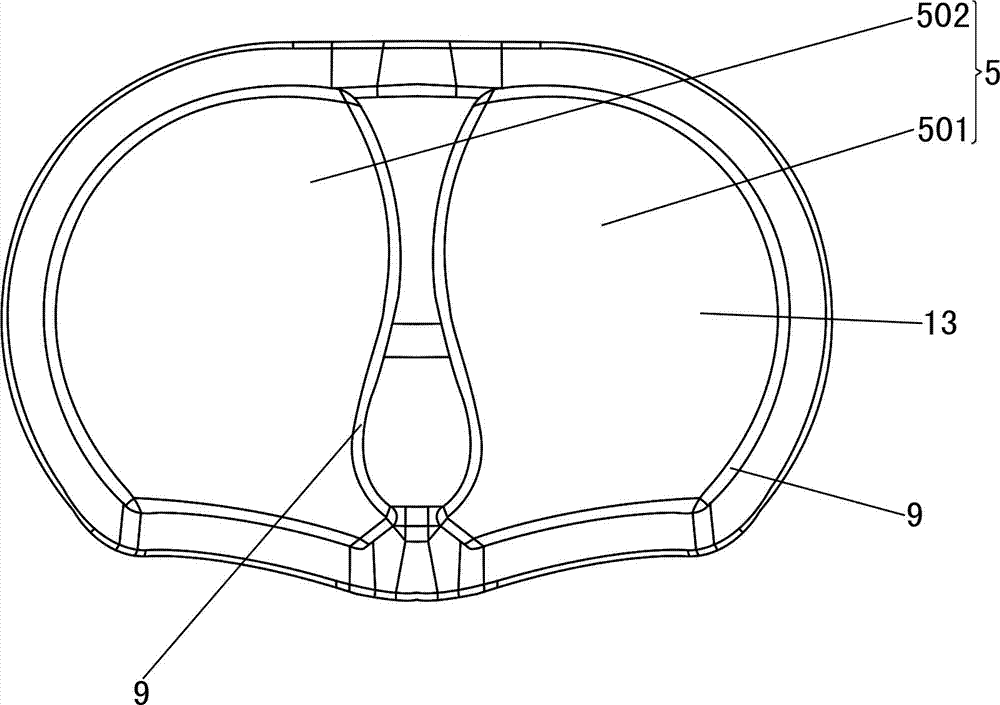

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 and Figure 5 As shown, this automatic breast cup thermoforming shearing machine includes a frame 1, an upper die table 2, a lower die table 3, an upper die 4, a lower die 5, an upper heating device 6, a lower heating device 7, a hydraulic pressure Cylinder 8 and circular cutter 9; upper die table 2 is fixedly installed on frame 1; lower die table 3 is installed on guide post 10 of frame 1 and can slide up and down along guide post 10; upper die 4 is installed on upper die The lower surface of the table 2; the lower mold 5 is installed on the upper surface of the lower mold table 3; the hydraulic cylinder 8 is installed on the frame 1, and the piston rod 11 of the hydraulic cylinder 8 is connected with the lower mold table 3; the upper mold 4 includes two upper molds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com