Automatic feeding device capable of reducing occupational injury rate for celadon blank mud manufacturing and rolling

A technology of automatic feeding device and work-related injury rate, which is applied in the field of celadon mud production, can solve the problems of reduced service life of the grinder, high physical exertion of workers, and unstable feeding control, so as to prevent overload operation, improve grinding efficiency, The effect of saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

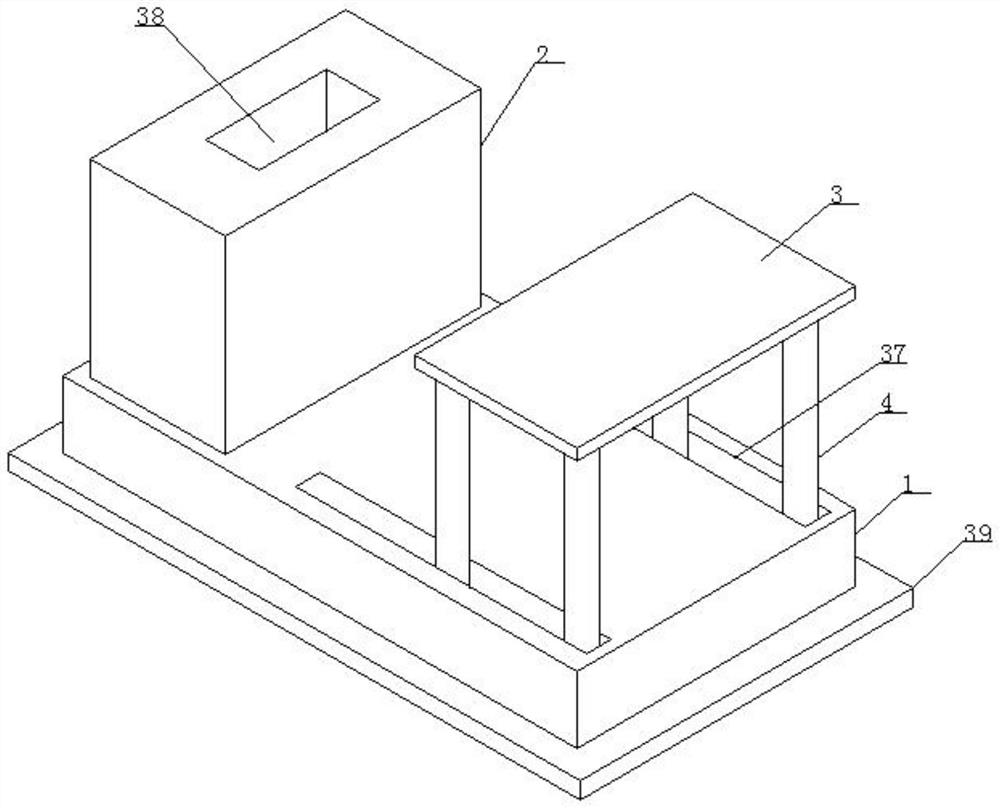

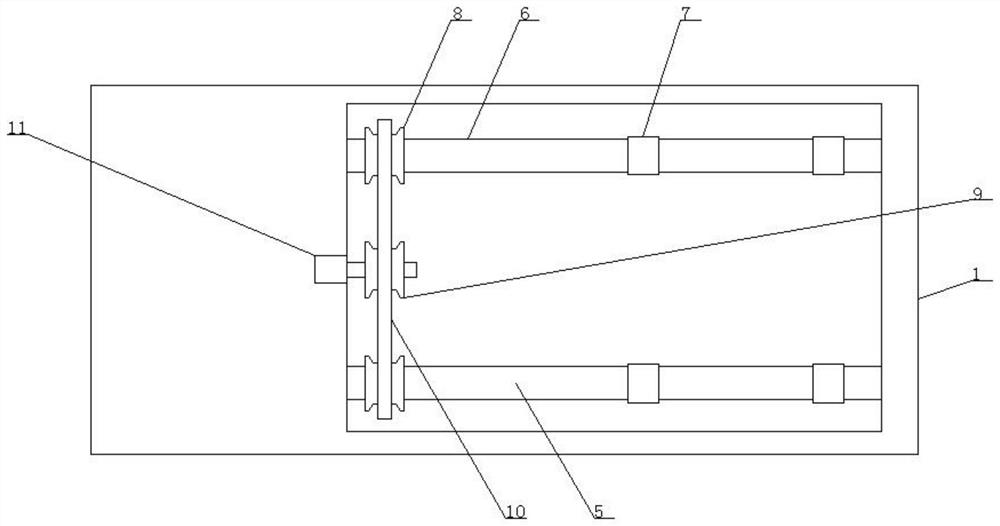

[0029] Such as Figure 1-5 As shown, according to the embodiment of the present invention, the automatic feeding device for making celadon mud for rolling and reducing the rate of work injury includes a base 1 and a grinder 2 located at the top of the base 1, above the base 1 and A workbench 3 is provided on one side of the grinder 2, and a number of evenly distributed support columns 4 are arranged at the bottom end of the workbench 3, and the bottom ends of the support columns 4 extend into the base 1, Said base 1 is provided with a screw mandrel 1 5 and a screw mandrel 2 6 which are arranged symmetrically, and said screw mandrel 1 5 and said screw mandrel 2 6 are respectively provided with movable blocks connected with a plurality of said supporting columns 4 7. The first screw mandrel 5 and the second screw mandrel 6 are equipped with driven wheels 8 respectively, and a transmission wheel 9 is arranged between the first screw mandrel 5 and the second screw mandrel 6, and t...

Embodiment 2

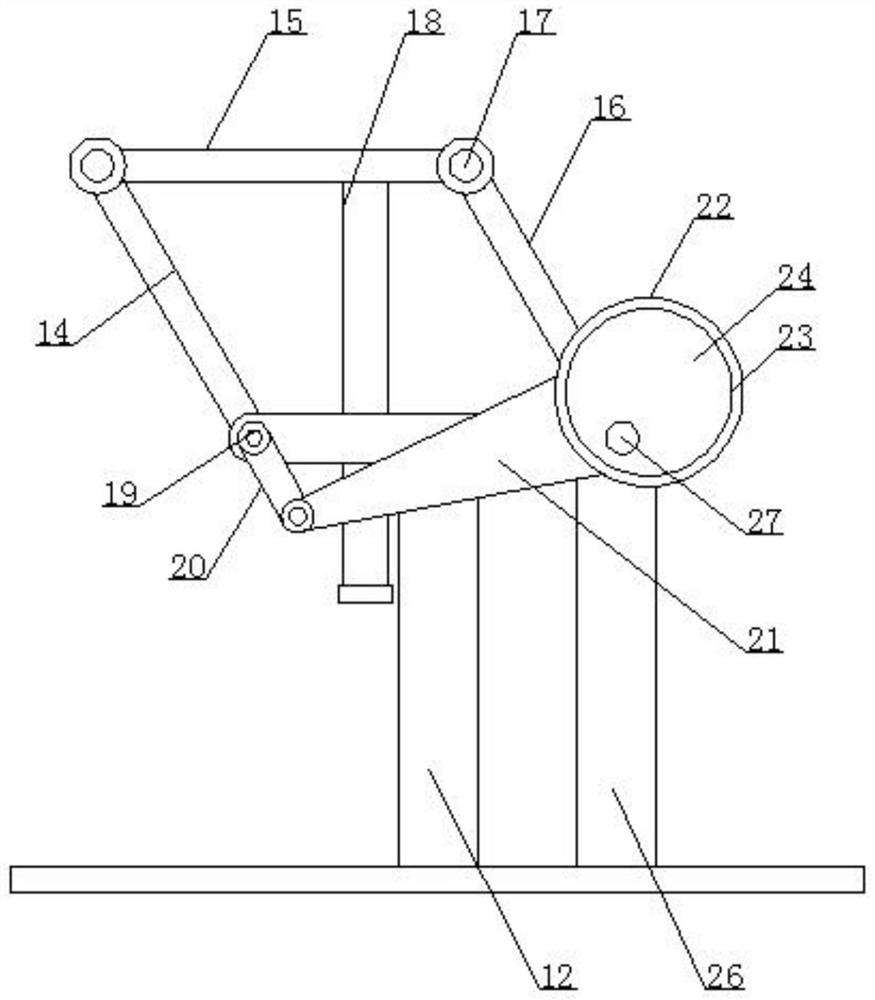

[0032] Such as Figure 1-5 As shown, the cylinder body 18 is a cavity structure with an open bottom end, and the bottom end of the cylinder body 18 is provided with a matching collar 28, and the cylinder body 18 is provided with a horizontal partition 29 , the top inside the barrel 18 is provided with a placement groove 30 , the top inside the placement groove 30 is provided with an electric telescopic rod 31 , and the bottom end of the electric telescopic rod 31 is connected with the top of the partition 29 .

Embodiment 3

[0034] Such as Figure 1-5As shown, the bottom end of the collar 28 is provided with a through hole 32, and the through hole 32 is symmetrically provided with a sealing sheet 33 that matches it, and the collar 28 is provided with a sealing sheet 33 that matches the sealing sheet 33. The slideway 34, one side in the slideway 34 is provided with an electromagnet 35 that is compatible with the sealing sheet 33, and an electromagnetic 35 that is compatible with the electromagnet 35 is provided in the sealing sheet 33. Iron two 36, the ring 22 is a tapered structure, and the aperture of the through hole 32 is smaller than the aperture of the cylinder 18, the connecting rod 15 is connected with the movable rod one 14 through a movable shaft, and The top end of the base 1 is provided with a travel groove 37 matching with the support column 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com