Anti-drop structure for regulating valve bushing

A technology of anti-dropping structure and regulating valve, applied in the direction of valve shell structure, lift valve, valve details, etc., can solve the problems of corrosion and falling off of hexagon socket flat-end set screws, affecting valve adjustment and sealing performance, and stopping the whole set of devices, etc. Hazardous machining operations, quick and reliable assembly, reduced dimensional tolerance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

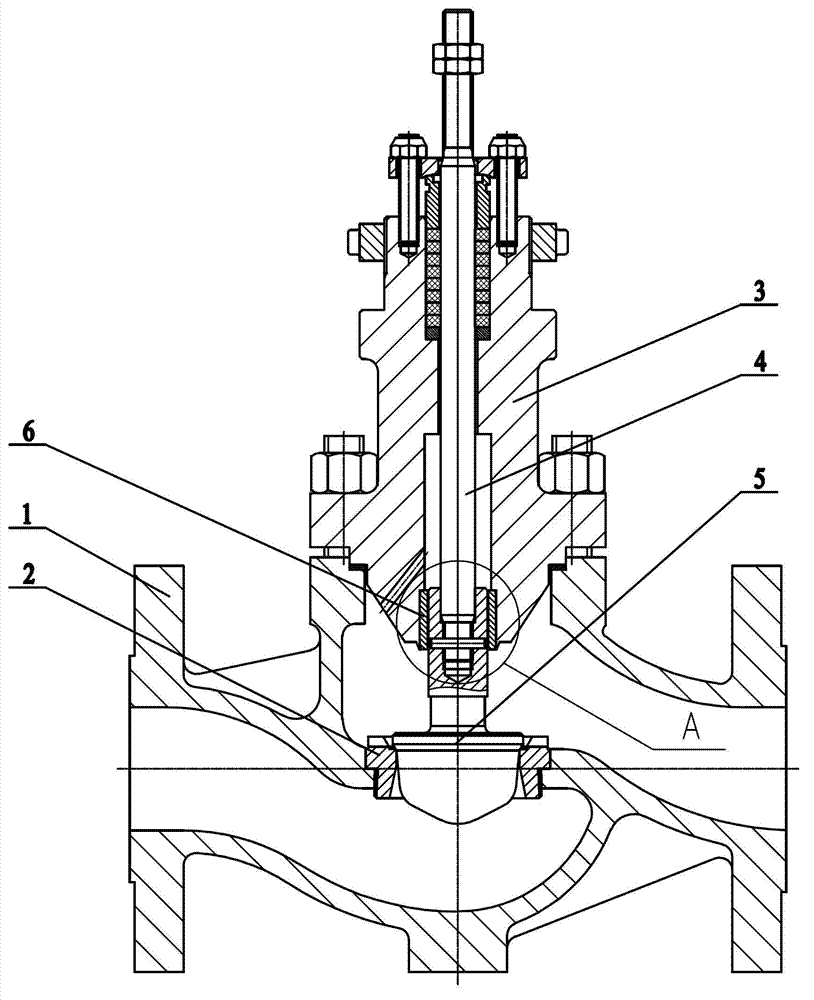

[0022] Such as figure 1 , 2 , 3 shows: the control valve bushing anti-off structure, including valve body 1, valve seat 2, valve cover 3, valve stem 4, valve core 5 and bushing 6, valve seat 2 is fixed in valve body 1, A bonnet 3 is fixed on the valve body 1, a valve stem 4 is inserted into the bonnet 3 for sliding sealing, and a valve core 5 is fixed at the bottom end of the valve stem 4,

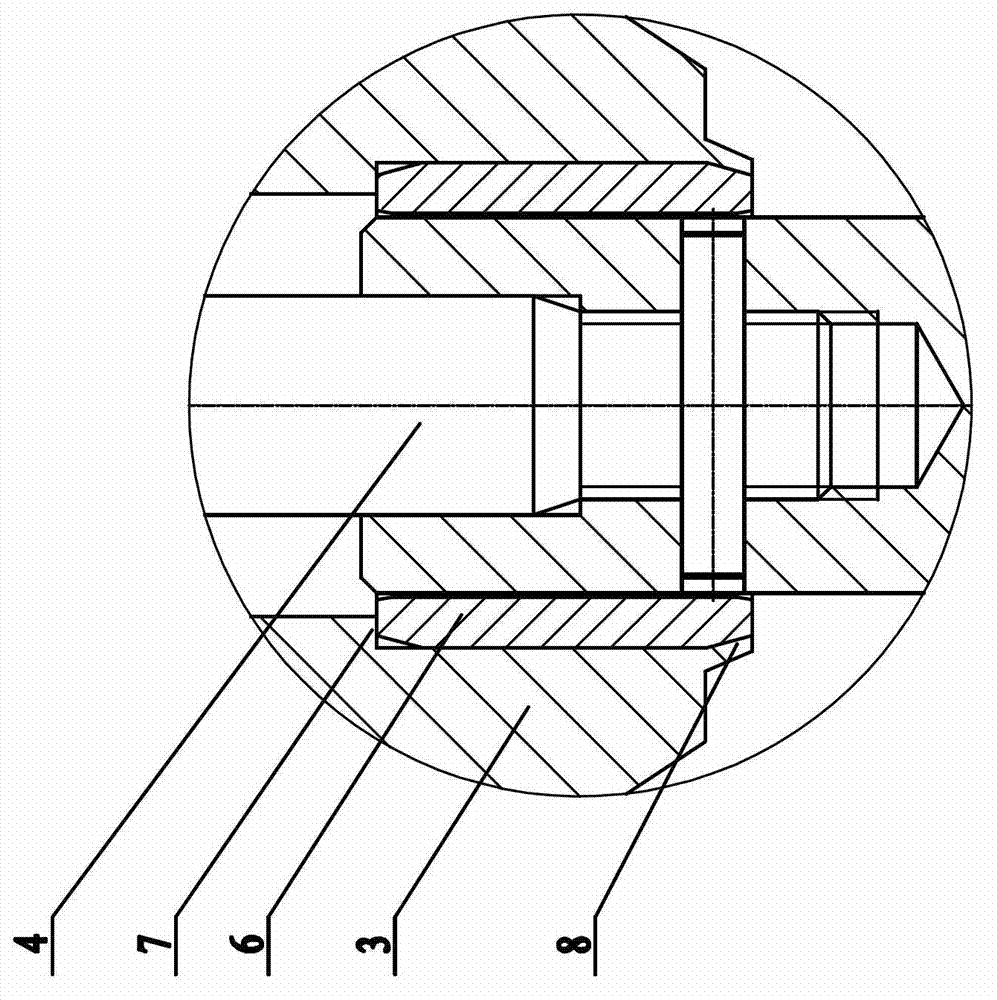

[0023] One end surface of the bush 6 is in contact with the limiting step 7, the outer edge of the other end of the bush 6 is provided with a limiting outer cone, and the other end of the bushing 6 is in contact with the limiting inner cone of the extrusion turning 8. surface contact.

[0024] The bottom end of the valve cover 3 is provided with the extruding flange 8, the extruding flange 8 has a limiting inner cone surface, and the limiting inner conical surface of the extruding flange 8 is in contact with the outer edge of the bottom end of the bushing 6. The limiting outer cone surf...

Embodiment 2

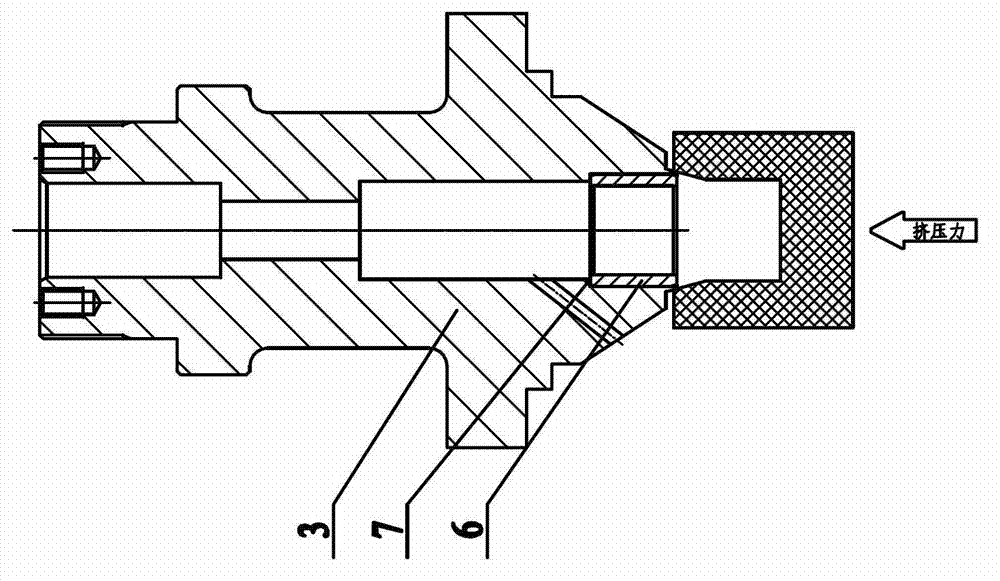

[0028] Such as Figure 4 , 5 , 6: the control valve bushing anti-off structure, including valve body 1, valve seat 2, valve cover 3, valve stem 4, valve core 5 and bushing 6, valve seat 2 is fixed in valve body 1, A valve cover 3 is fixed on the valve body 1, and a valve stem 4 is inserted into the valve cover 3 in a sliding and sealing manner, and a valve core 5 is fixed at the bottom end of the valve stem 4. The steps 7 offset each other, and the outer edge of the other end of the bush 6 is provided with a limit outer cone surface, and the other end of the bush 6 is in contact with the limit inner cone surface of the extruded flange 8 .

[0029] A bushing seat 9 is also provided under the valve cover 3, and the bottom end of the bushing seat 9 is provided with the limiting step 7, and the bottom end surface of the bushing 6 is offset against the limiting step 7, and the bushing seat 9 The top end portion is provided with the extrusion flanging 8, the extrusion flange 8 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com