A chip package electrode and its preparation method and chip package structure

A chip packaging structure, chip packaging technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of high risk of mechanical damage, poor heat dissipation of chips, etc., to reduce the risk of mechanical damage, reduce damage, and increase electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Preparation method of chip package electrode

[0071] The present invention also provides a method for preparing the chip packaging electrode, comprising:

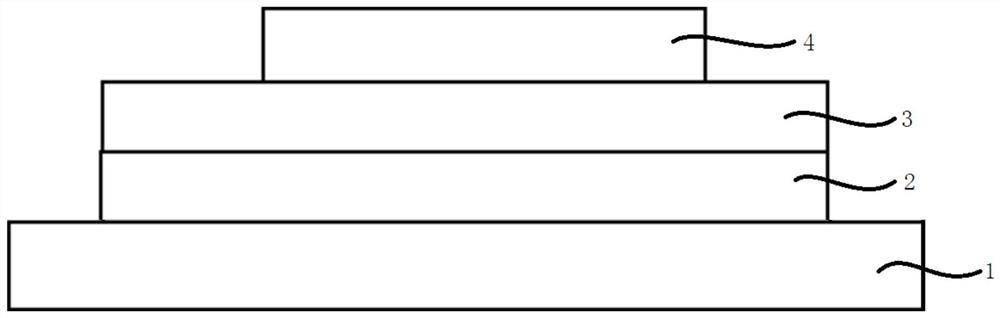

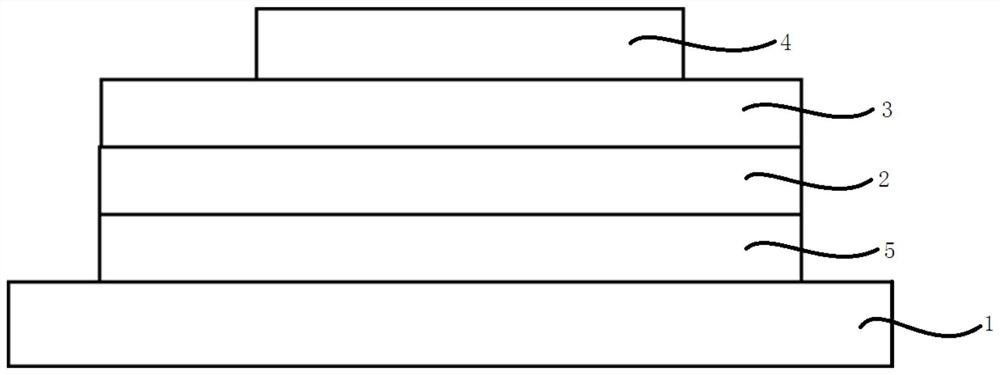

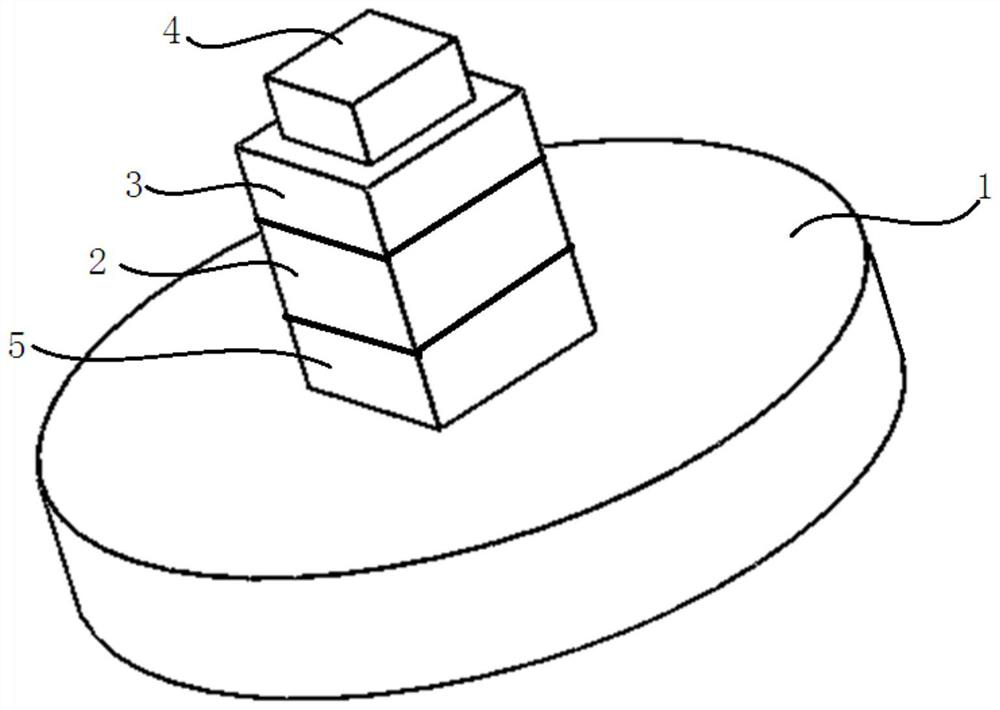

[0072] A first molybdenum-copper alloy layer 2 , an elastic layer 3 and a second molybdenum-copper alloy layer 4 are sequentially formed on the electrode plate 1 .

[0073] All conventional preparation methods capable of forming the above chip package electrode structure are within the protection scope of the present invention.

Embodiment approach

[0074] As an optional embodiment of the preparation method, the preparation is carried out according to the following steps:

[0075] The first molybdenum-copper alloy layer, the elastic layer and the second molybdenum-copper alloy layer are sequentially formed on the electrode plate by 3D printing technology to obtain alloy formed parts;

[0076] The alloy formed part is heat-treated to obtain the chip packaging electrode.

[0077] The application of 3D printing technology is conducive to the flexible adjustment of molybdenum and copper content in the first molybdenum-copper alloy layer and the second molybdenum-copper alloy layer, and is conducive to the uniform distribution of copper and elastomer in the elastic layer.

[0078] The specific operation method is given below:

[0079] (1) Lay copper powder on the electrode plate, heat the copper powder in the selected area with a laser beam, fuse the copper powder in the selected area, form a laser cladding layer on the surfa...

Embodiment 1

[0105] This embodiment provides a chip packaging electrode, the preparation method of which is as follows:

[0106] (1) Lay copper powder on the copper plate, heat the copper powder in the selected area with a laser beam, fuse the copper powder in the selected area, form a laser cladding layer on the surface of the copper plate, print to a predetermined height, and obtain a copper metal layer , the thickness is 10mm, the particle size of copper powder is 15-60μm, and the oxygen content is lower than 2000ppm;

[0107] (2) Lay the mixed powder of molybdenum and copper on the copper metal layer obtained in step (1), heat the mixed powder of molybdenum and copper in the selected area with a laser beam, and fuse the mixed powder of molybdenum and copper in the selected area , a laser cladding layer is formed on the surface of the copper metal layer. As the printing height increases, the mass percentage of molybdenum in the mixed powder of molybdenum and copper increases from 0% to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com