Drilling machine

A drilling machine and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of low construction efficiency, prone to work-related injuries, and high cost of drilling machines, so as to reduce the input of manpower and material resources and save construction time , High drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

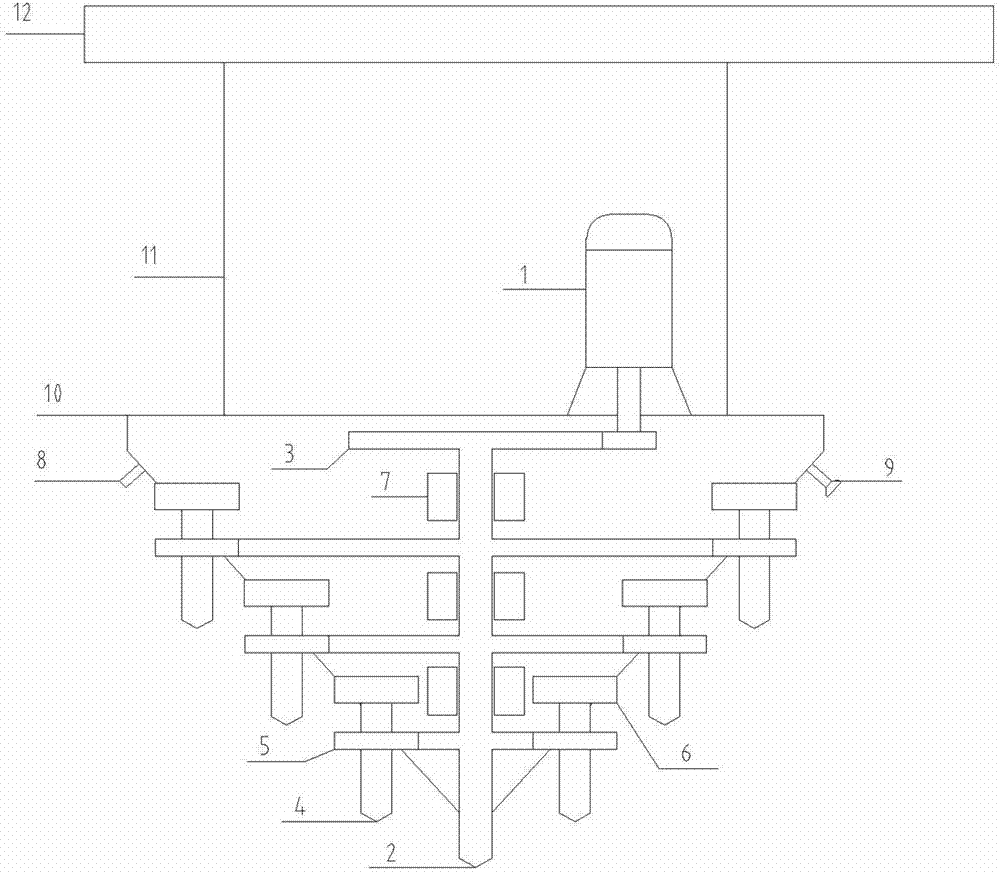

[0009] A drilling machine, comprising a motor 1, a main drill bit 2, a gear set 3, an auxiliary drill bit 4, an auxiliary drill bit gear set 5, an auxiliary drill bit fixing frame 6, a gear set fixing frame 7, an outer shell frame 10, a wire rope 11 and The ground frame 12, the gear teeth on the power output shaft of the gear set 3 and the motor 1 are meshed, the auxiliary drill bit holder 6 is fixedly installed on the shell frame 10, the main drill bit 2 is provided with the gear set 3, and the auxiliary drill bit 4 is provided with the gear set 3. There is an auxiliary drill gear set 5, an auxiliary drill bit 4 is arranged on the auxiliary drill bit fixed frame 6, an auxiliary drill bit gear set 5 is arranged on the auxiliary drill bit 4, the auxiliary drill bit gear on the auxiliary drill bit 4 meshes with the gear 3 on the main drill bit 2, and the gear Group 3 is fixed on the shell frame 10 by the gear set fixing frame 7, and the ground frame 12 is provided with a steel wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com