Feeding and discharging buffer mechanism with environment control function

A caching mechanism and environmental technology, applied in the direction of conveyor objects, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of increasing production steps, reducing the yield rate of main line production, increasing fragmentation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

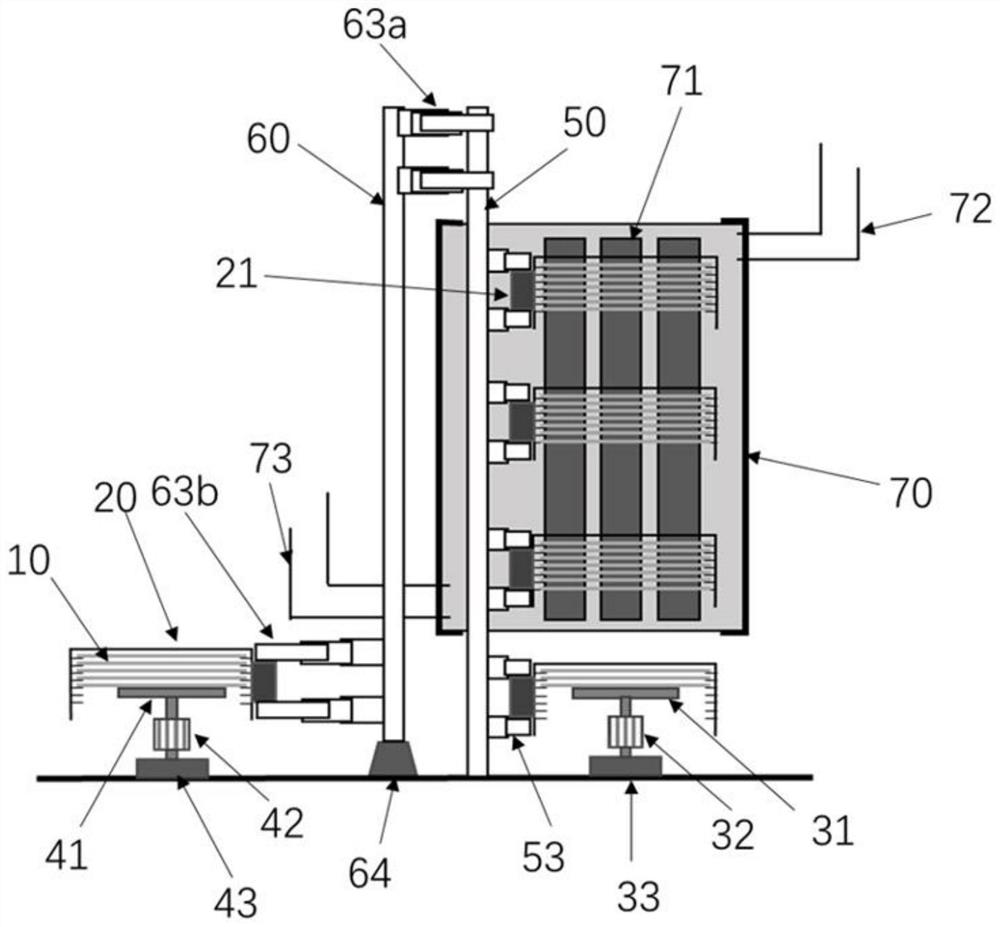

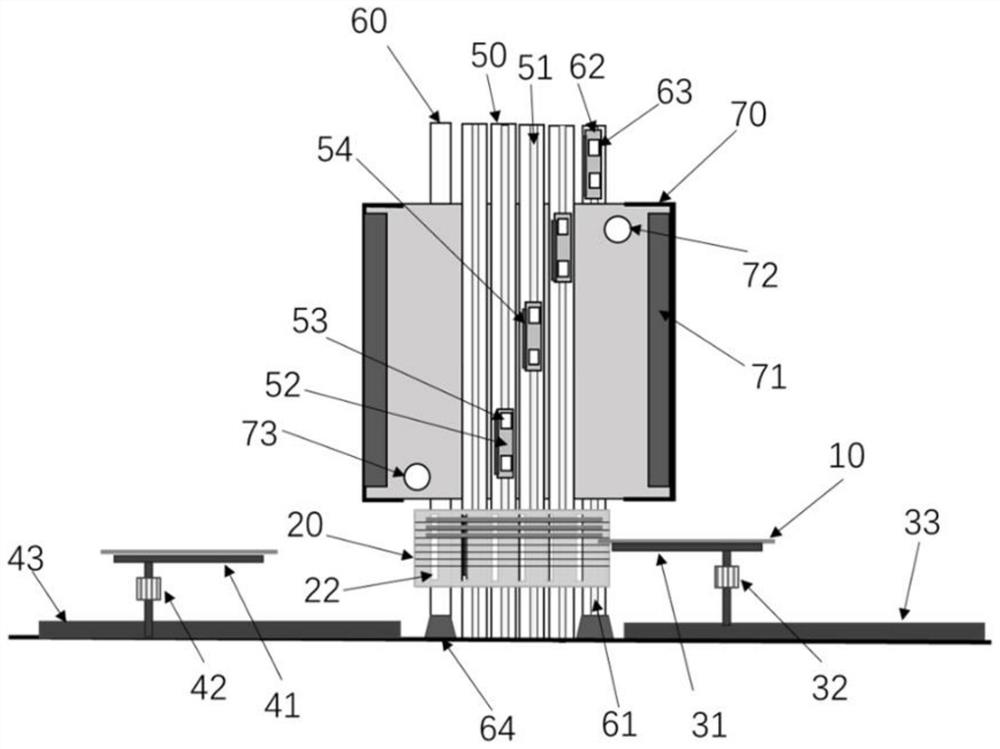

[0025] Such as figure 1 and figure 2 As shown, a loading and unloading buffer mechanism with environmental control includes an environmental control room 70, a feeding lifting mechanism 50, a discharging lifting mechanism 60, a feeding inserting device 31, a discharging and taking device 41, and a storage box 20. Wherein, each feeding lifting mechanism 50 includes a feeding motion slide rail 51 , a feeding motion module, and a feeding clamp 53 . Each discharge lifting mechanism 60 includes a discharge motion slide rail 61 , a discharge motion module 62 and a discharge clamp 63 .

[0026] The back of each storage box 20 is provided with a grasping groove 21, so that the feeding clamp 53 of the feeding lifting mechanism 50 can grab the storage box 20, and is driven by the feeding movement module 52 through a motor, a top cylinder, etc. The driving part moves up and down along the feeding movement slide rail 51 . Similarly, the discharge clamp 63 of the discharge lifting mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com