Accurate online dilution system and dilution method thereof

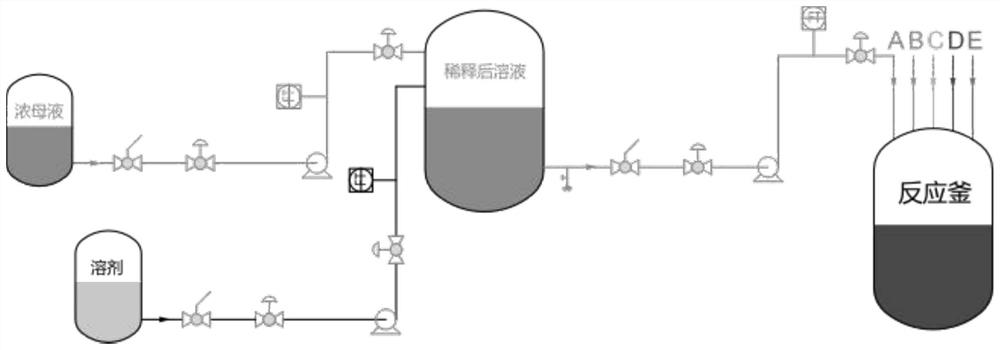

An accurate and pipeline technology, applied in the precise online dilution system and its dilution field, can solve the problem of inaccurate detection, and achieve the effect of ensuring the measurement accuracy, saving investment and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

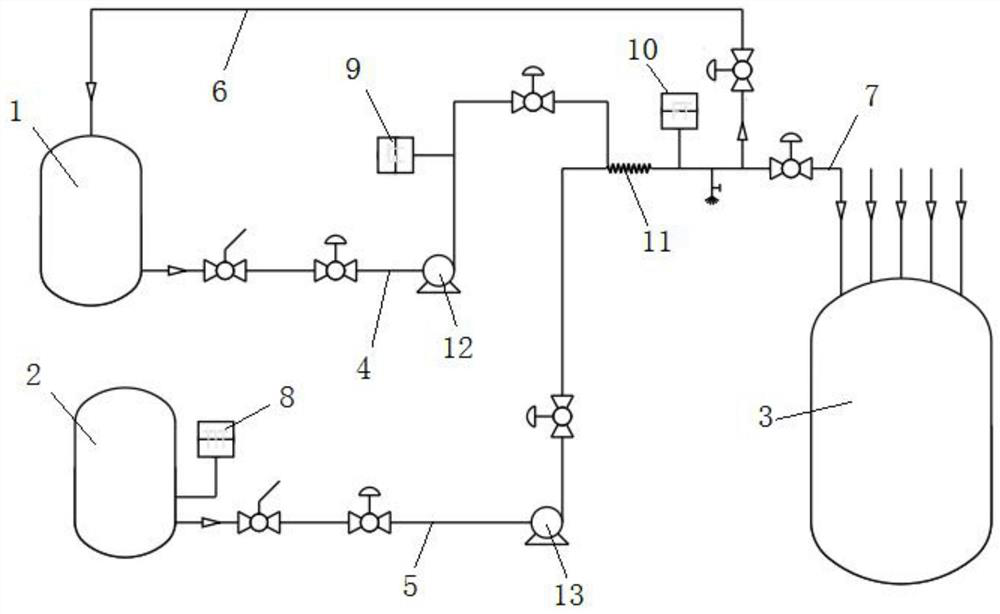

Examples

Embodiment 1

[0028] Pump into the reaction kettle with a temperature of 50°C, Fe 2+ FeSO at a concentration of 100g / l 4 The solution is 40KG, the feed rate is 80KG / h, and the mother liquor is FeSO of unknown solution 4 solution, the solvent is pure water.

[0029] first step:

[0030] Set target temperature 50°C, target Fe 2+ The concentration is 100g / l, the target FeSO4 solution quality is 40KG, set the diluted FeSO 4 The flow rate of the pipeline where the solution enters the reactor is 80KG / h;

[0031] The temperature of the pure water is monitored in the meter set 18, and the temperature, density, flow rate and cumulative mass flow are monitored in the meter set 2 9 and the meter set 3 10, and the flow rate of the pure water is controlled by the frequency conversion motor PID;

[0032] Open the pump one 12 and valve of pipeline one 4 and pipeline three 6, the FeSO of the mother liquor that detects 4 The temperature is 40.1°C and the density is 1.2412g / cm 3 , the pure water tempe...

Embodiment 2

[0036] Pump temperature 30°C, Fe 2+ FeSO at a concentration of 90g / l 4 The solution is 50KG, the feed rate is 60KG / h, and the mother liquor is FeSO of unknown solution 4 solution, the solvent is pure water.

[0037] first step:

[0038] Set target temperature 30°C, target Fe 2+ Concentration 90g / l, target FeSO 4 The quality of the solution is 50KG, set the diluted FeSO 4 The flow rate of the pipeline where the solution enters the reactor is 60KG / h;

[0039] The temperature of the pure water is monitored in the meter set 18, and the temperature, density, flow rate and cumulative mass flow are monitored in the meter set 2 9 and the meter set 3 10, and the flow rate of the pure water is controlled by the frequency conversion motor PID;

[0040] Open the pump one 12 and valve of pipeline one 4 and pipeline three 6, the FeSO of the mother liquor that detects 4 The temperature is 42.3°C and the density is 1.2376g / cm 3 , the pure water temperature is room temperature 32.8 ℃, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com