Control system of continuous rolling mill

A control system and continuous rolling mill technology, applied in the physical field, can solve the problems of hindering continuous rolling mill 4 roll change, maintenance, inconvenience for operators to observe the site, project occupation and increased investment, etc., to reduce equipment investment and low cost , The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

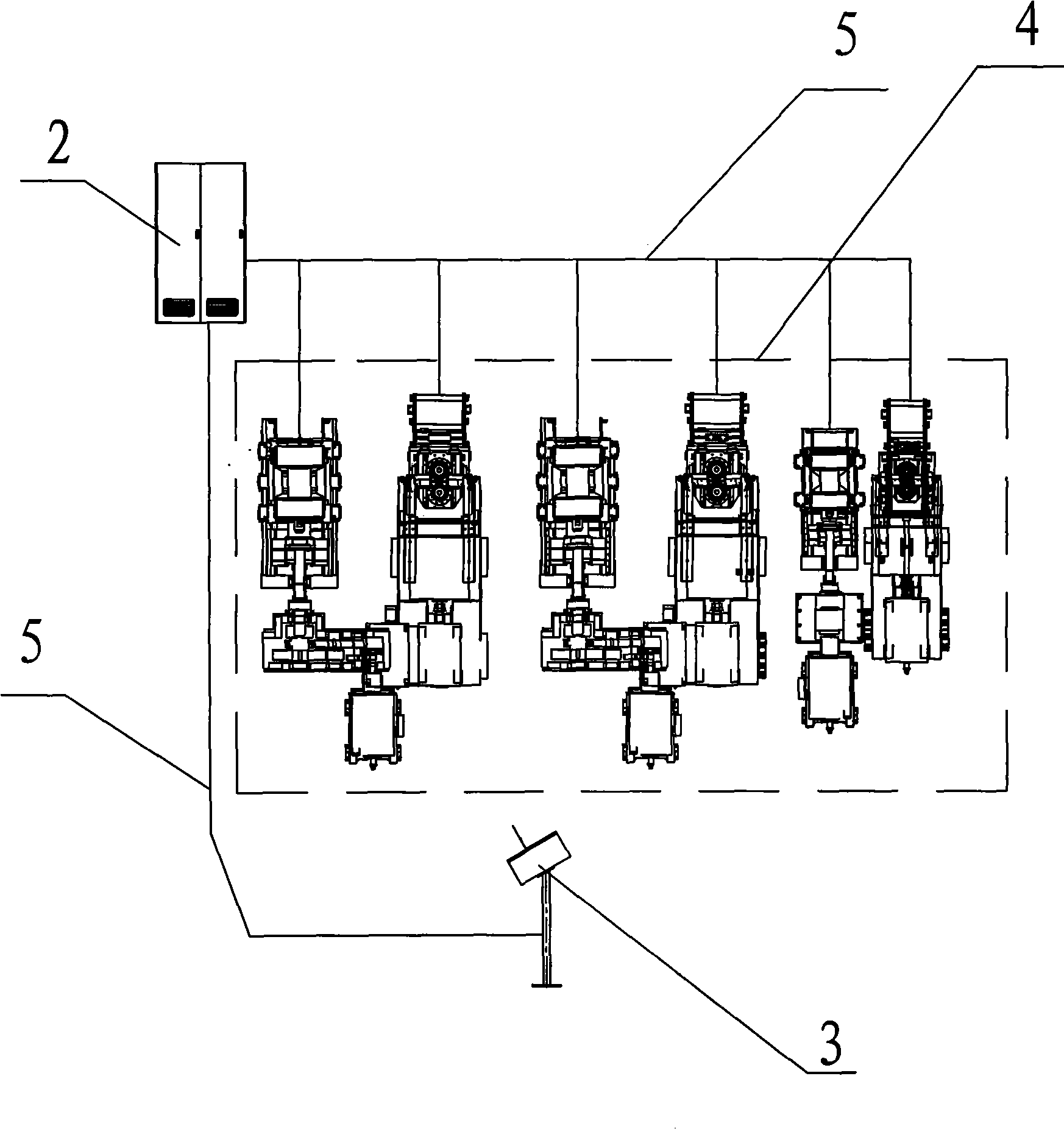

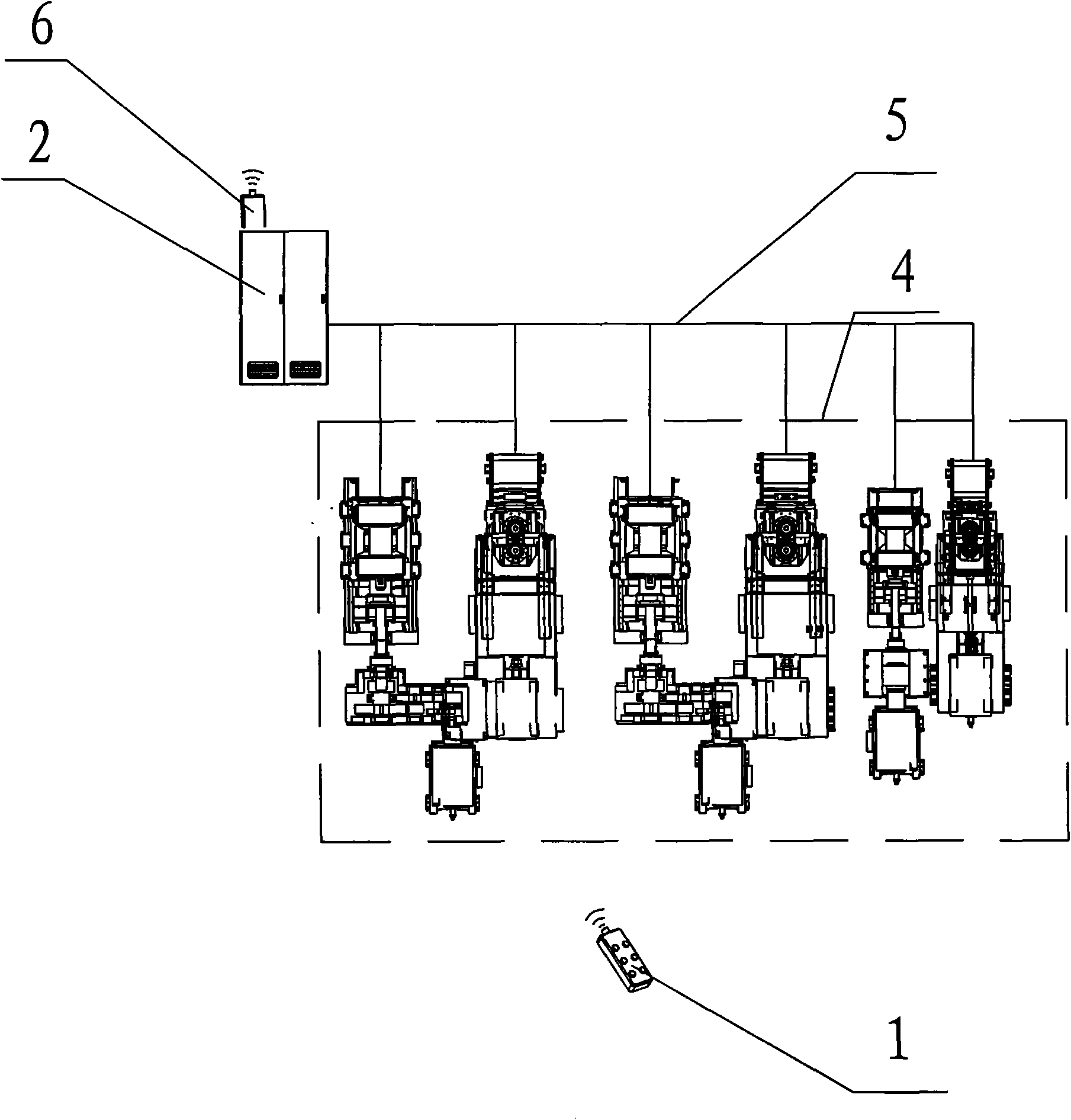

[0015] Such as figure 2 As shown, a continuous rolling mill control system includes an I / O box 2, a continuous binding unit 4 and a data line 5. The system also includes: a remote control terminal 1 and a receiver / transmitter 6, and the remote control terminal 1 transmits The line sends a signal to the receiver / transmitter 6, and the receiver / transmitter 6 processes and converts the signal and transmits it to the I / O box 2, and the I / O box 2 transmits the control signal to each functional block of the connecting unit 4 through the data line 6 , to achieve on-site remote control. Due to the use of wireless transmission, the on-site console in the traditional operating system and the cable between the console and the I / O box are eliminated, reducing equipment investment and saving workshop space, and the remote control terminal is small in size and easy to ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com