Working roll replacing device and working roll replacing method for heavy and medium plate mill

A roll changing device and work roll technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problems of unit working efficiency, low degree of automation, long replacement time, etc., and shorten the replacement time. Roll time, high degree of automation, and the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

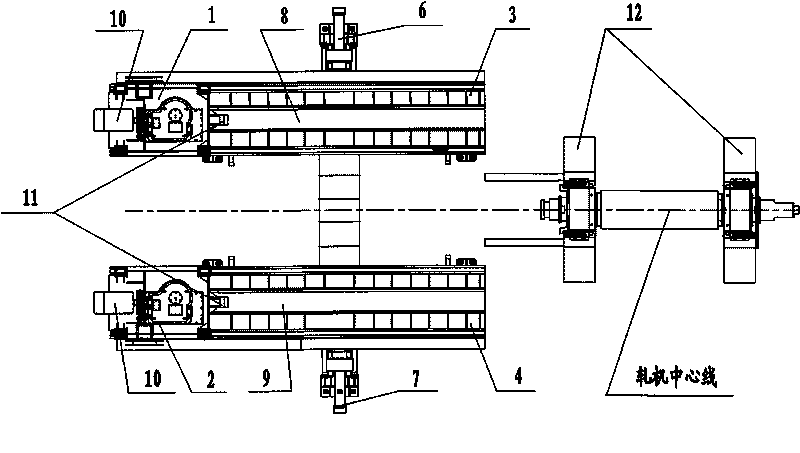

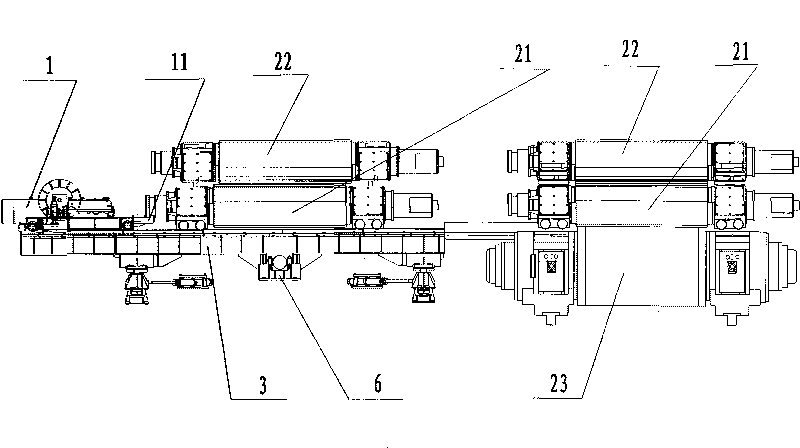

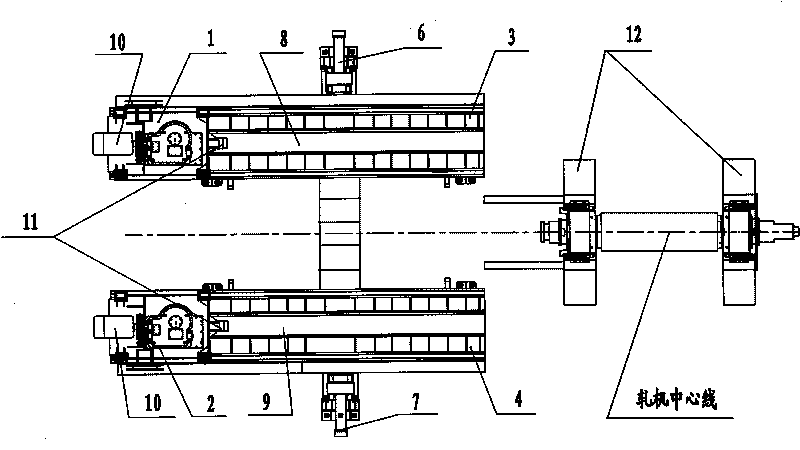

[0018] see figure 1 , the work roll changing device for medium and heavy plate mills of the present invention comprises two roll changing trolleys 1, 2, two traverse trolleys 3, 4, a transverse guide rail 5, a pair of hydraulic cylinders 6, 7 and two longitudinal guide rails 8, 9, of which,

[0019] The transverse guide rail 5 is arranged outside one side of the rolling mill frame 12 perpendicularly to the center line of the rolling mill;

[0020] A pair of hydraulic cylinders 6, 7 are located at both ends of the transverse guide rail 5;

[0021] The two traversing trolleys 3, 4 can move along the transverse guide rail 5 and are respectively connected to the piston rods 60, 70 of the hydraulic cylinders 6, 7;

[0022] The two longitudinal guide rails 8, 9 are respectively arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com