Ten-gate holeless rod continuous rolling process

A technology without holes and bars, which is applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems of unclear sharpening law of the corner of the rolled piece, influence on the surface quality of the product, poor stability of the rolled piece, etc., and achieve production The process is stable and controllable, the annual operation rate is improved, and the deformation is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] Embodiment: product specification is the rolling of screw thread steel of φ 20mm, and steel grade is low alloy steel, and the width * height of billet cross-section is 150mm * 150mm, and rolling temperature is 1050 ℃, adopts ten passes without Pass continuous bar rolling process, the rolling parameters are as follows:

[0022] See the following table for the rolling parameters of ten-pass continuous rolling without holes:

[0023] Rolling parameter table of ten-pass continuous rolling without holes:

[0024]

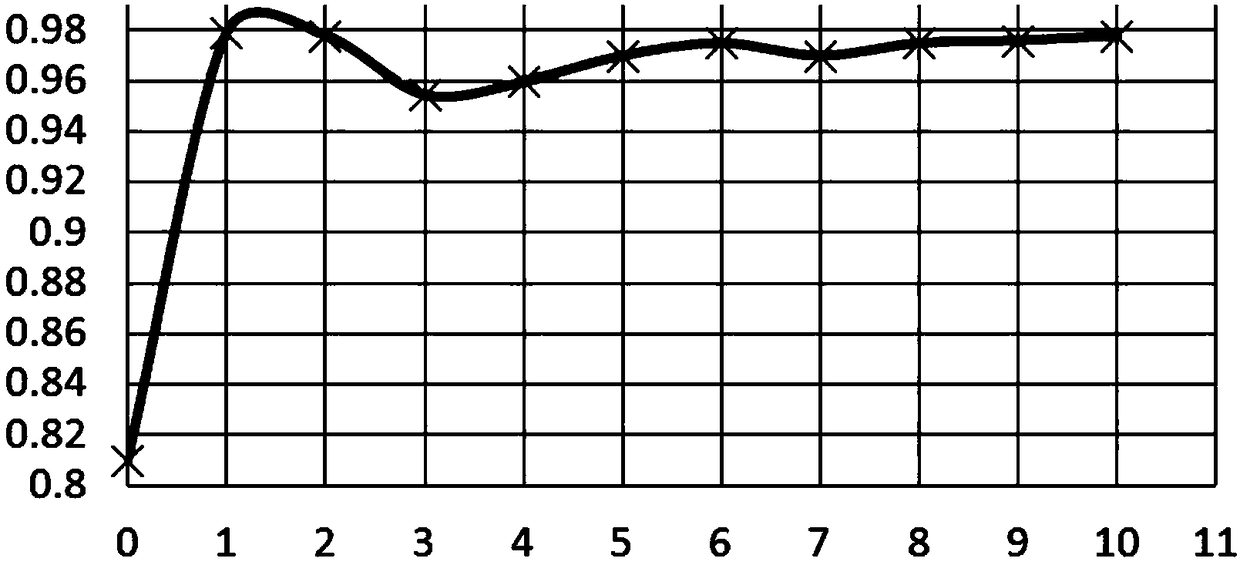

[0025] In the ten-pass continuous rolling without holes, the change curve of the corner sharpening coefficient of the rolled piece is shown in figure 1 , figure 1 Middle: The horizontal bottom line is the rolling pass, and the left vertical line is the corner sharpening coefficient of the rolled piece.

[0026] When the bar is rolled by this scheme, the biting condition of the rolled piece from the 10V stand without holes to the 11H stand with holes is norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com