A screw conveying device for metal pellets used in high temperature environment

A technology of screw conveying device and metal particles, applied in packaging and other directions, can solve the problems of short life of screw blades, variability of screw shafts, poor sealing performance, etc., to extend the overall life, reduce the frequency of inspection and maintenance, and solve the problem of easy wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

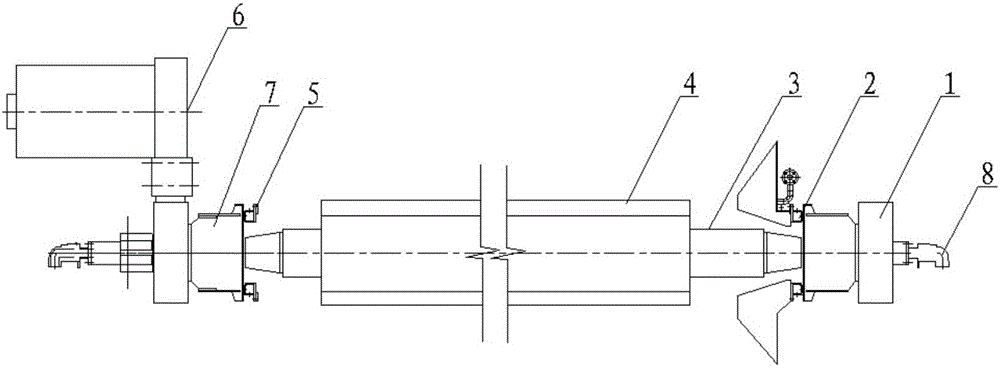

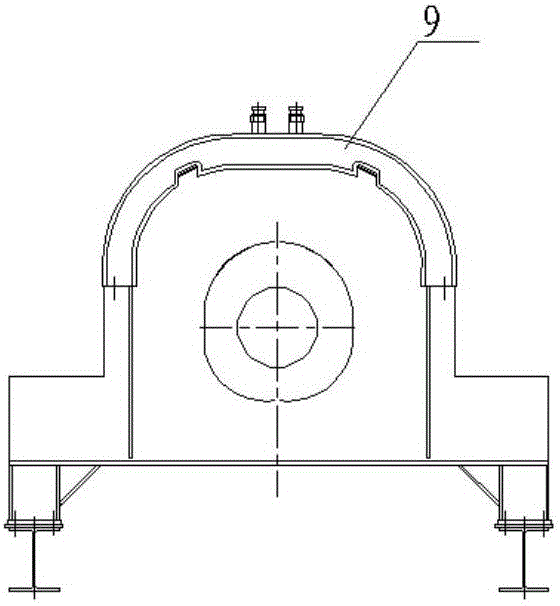

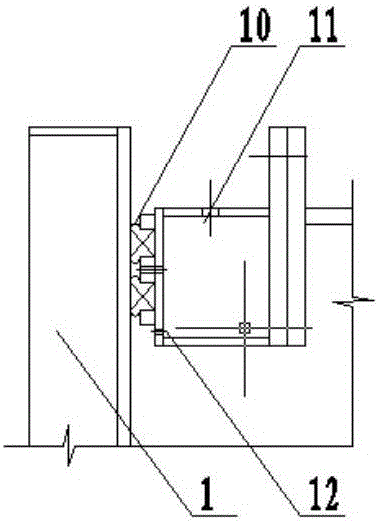

[0019] figure 1 — Figure 4 It is a specific embodiment of the present invention.

[0020] The invention includes: fixed support 1, fixed sealing head 2, shaft 3, spiral blade 4, movable sealing head 5, driving device 6, movable sealing head adjusting device 7, cooling water interface 8, water cooling cover 9, sealing rope 10, Sealing nitrogen interface 11, sealing nitrogen spout 12, adjusting bracket 13, positioning bolt 14 and adjusting cylinder 15. Wherein, the fixed support 1 is installed on the adjustment bracket 13, one end of the adjustment bracket 13 is connected to the outside through a pin shaft, and the other end is connected to the adjustment cylinder 15, and the adjustment cylinder 15 is used to drive the adjustment bracket 13 to lift; the positioning bolt 14 is installed On the adjustment bracket 13, it is used to adjust the height of the adjustment bracket 13 to avoid excessive wear of the helical blade 4; the helical blade 4 is welded on the shaft 3 by weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com