Breast-roll set replacement method and hoisting clamp thereof

A replacement method and rack roll technology are applied to metal rolling racks, manufacturing tools, transportation and packaging, etc., which can solve the problems of high labor intensity for workers, large volume of roll changing trolleys, inconvenient transportation and storage, etc., and achieve Improved work efficiency, shortened roll change time, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the examples.

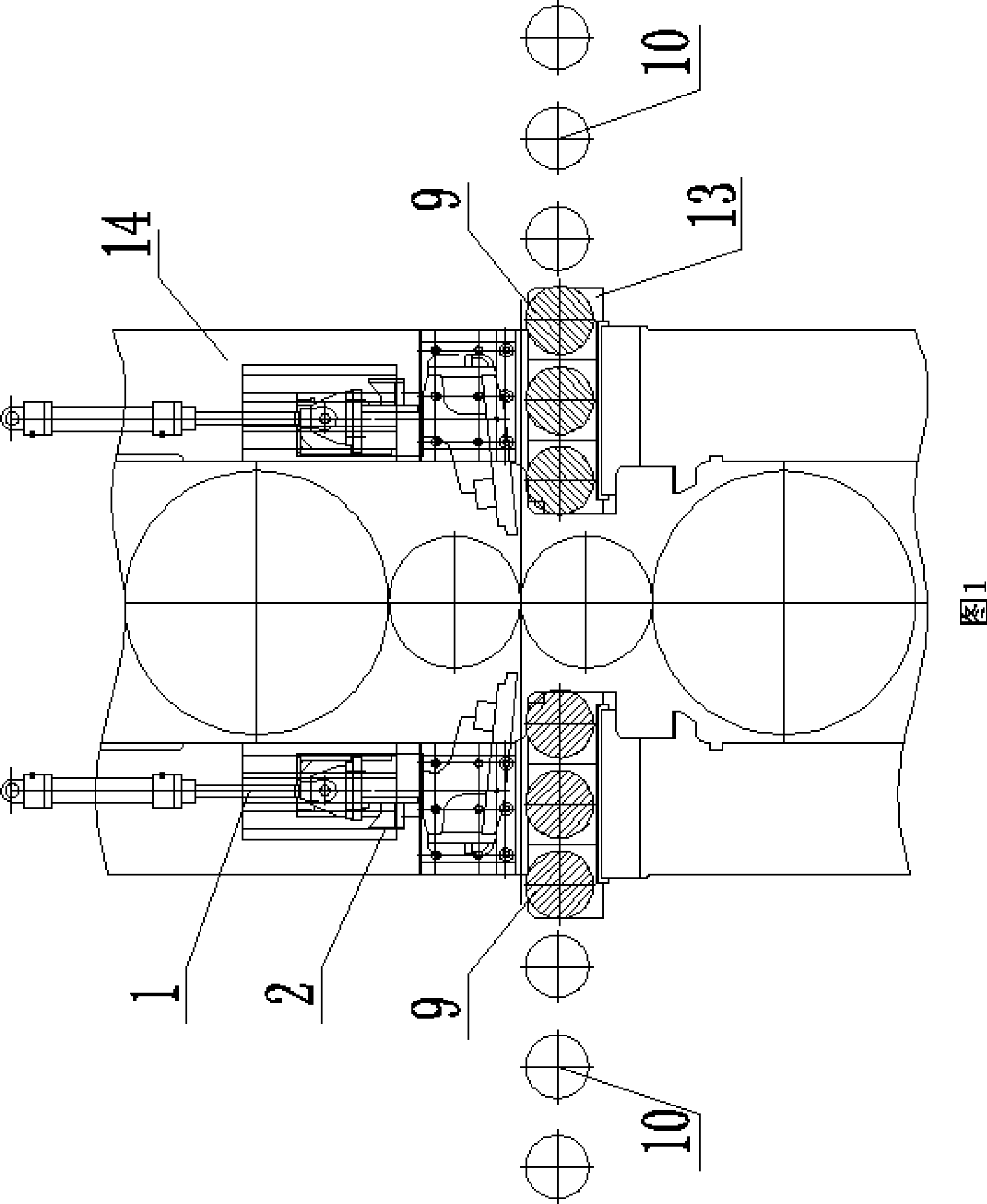

[0025] As shown in Figure 1, it is a schematic diagram of the frame roll structure of a reversible rolling mill for wide and thick plates. A working roller table 10 is installed and arranged at the front and rear of the frame archway 14 along the direction of the rolling line, and three rack rolls at the front and rear are installed in the frame archway 14. The frame roller group 13 that 9 forms, the top of corresponding front and back frame roller group 13 on the frame archway 14 is equipped with guide guard lifting cylinder 1 and guide guard frame 2. After working for a period of time, due to the wear and tear of the stand rollers 9, the stand roller set needs to be replaced. The replacement steps are as follows:

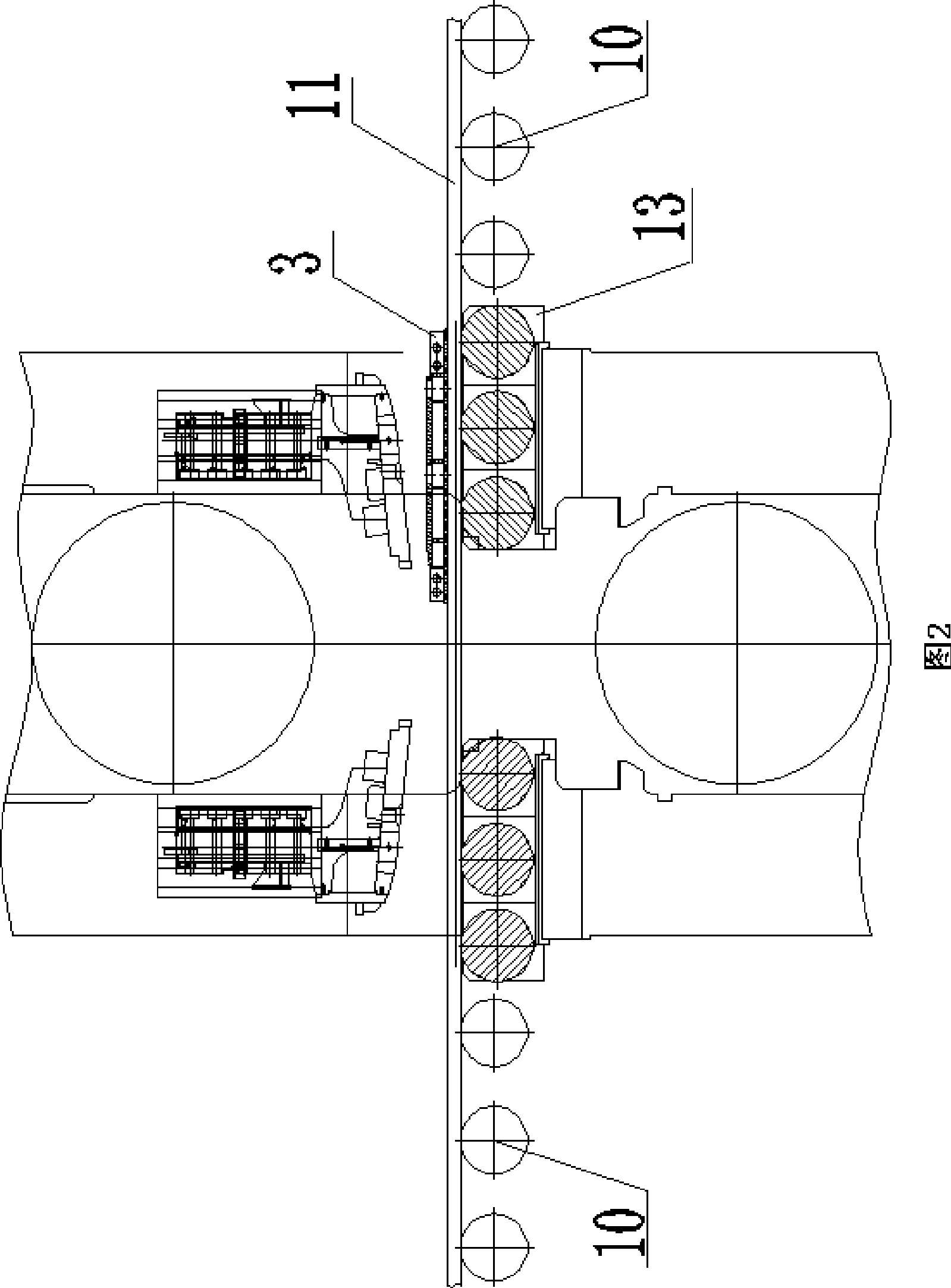

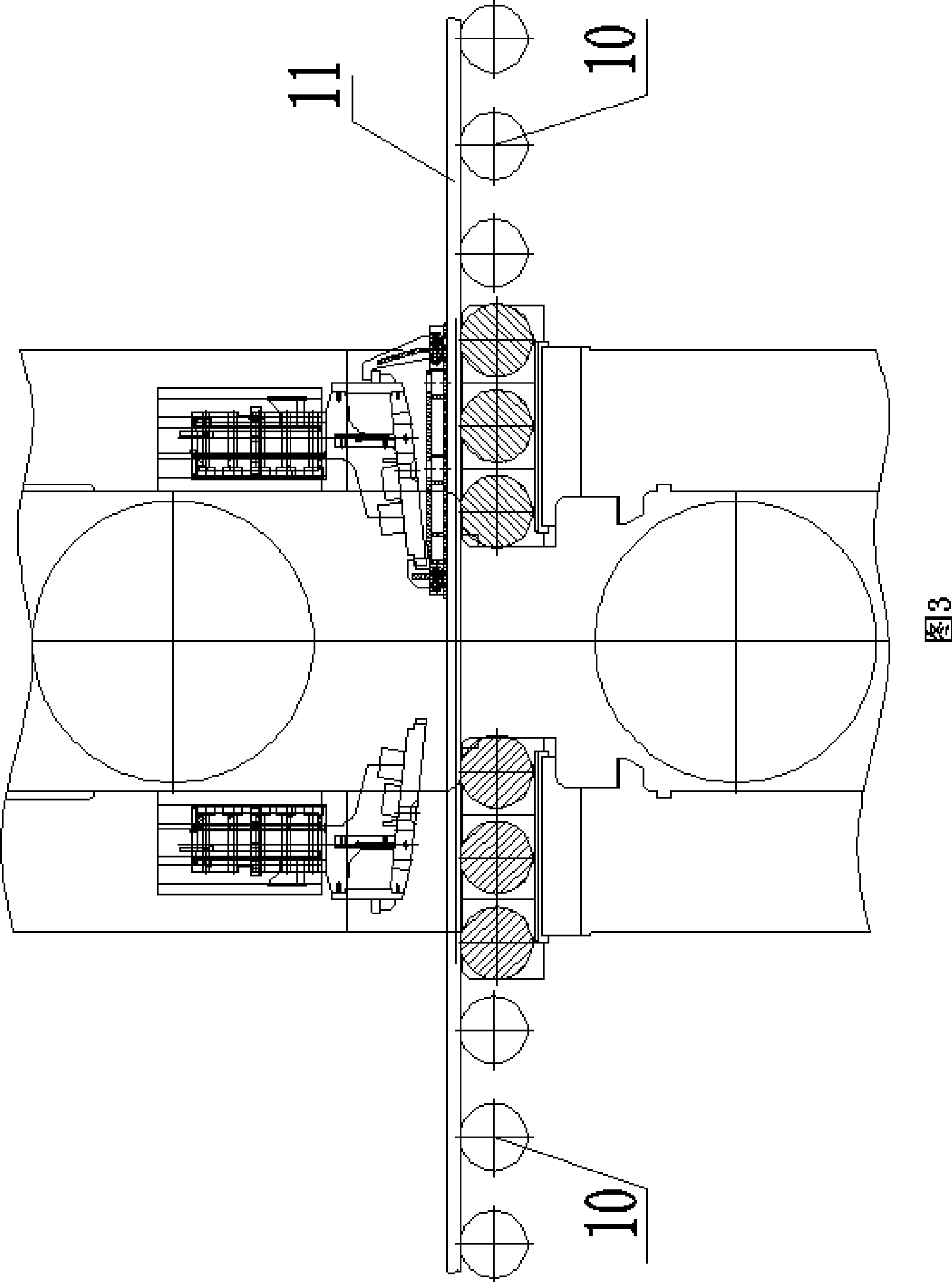

[0026] A. As shown in Figure 2, through the work roller table 10 will be as Figure 6 The two left and right spreaders 3 arranged left and right according to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com