Variable-stroke and variable-step-size roll motion alternating method

A variable step and variable stroke technology, applied in the field of variable stroke and variable step roll shifting, can solve problems such as work roll defects, and achieve the effects of improving wear uniformity, extending the length of the schedule, and improving the shape quality of the strip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

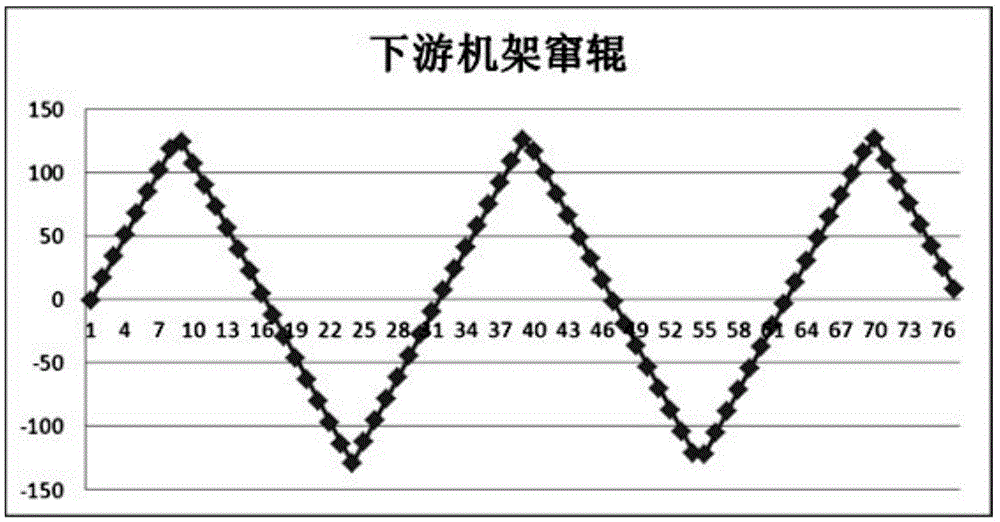

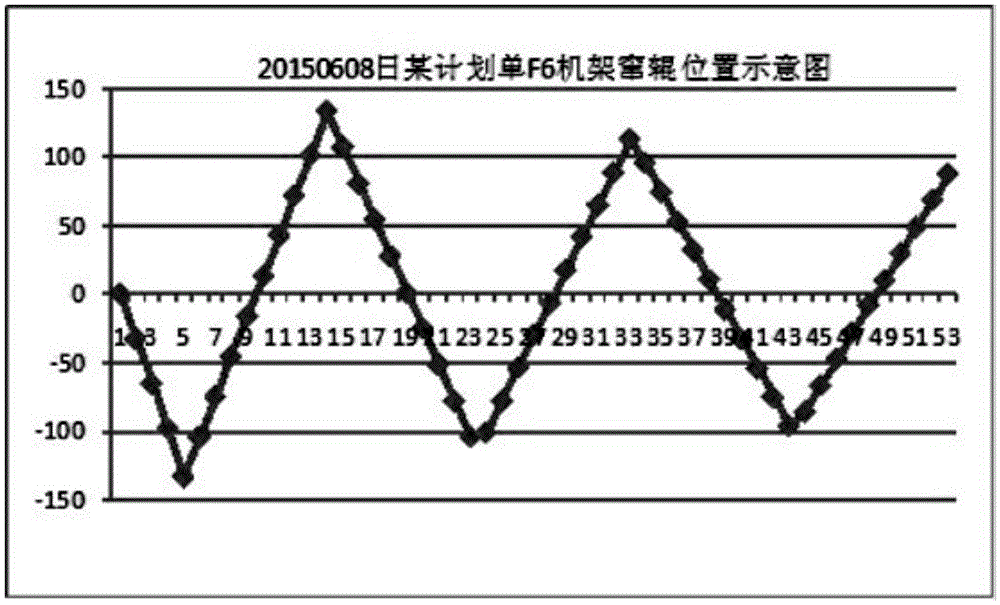

[0029] The embodiment of the present application provides a roll shifting method with variable stroke and step length to solve the problem of the conventional roll shifting method with equal stroke and equal step length. The work rolls form sharp "cat ears" due to local wear and tear, resulting in strip shape defects. Problems, can significantly improve the wear uniformity of the roll, improve the quality of the strip shape, and extend the length of the plan sheet.

[0030] The general idea of the technical solution of the embodiment of the present application is as follows:

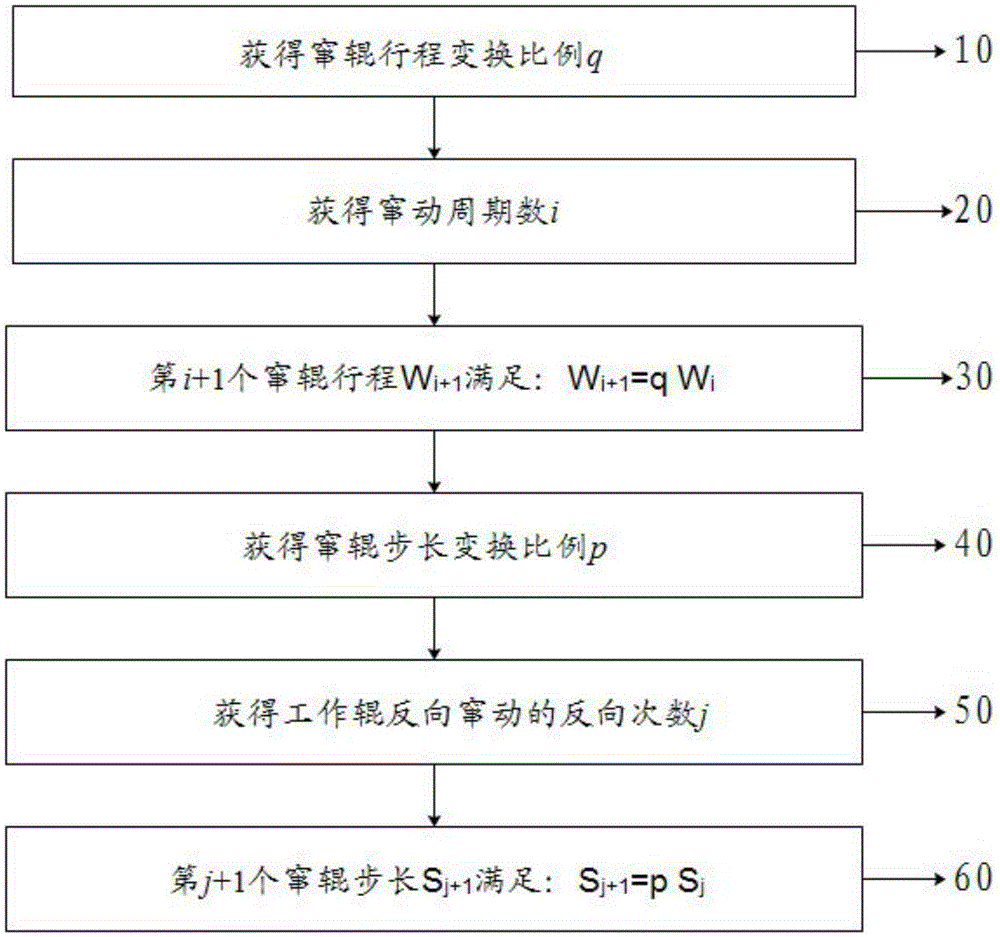

[0031] A roll shifting method with variable stroke and step length, obtaining the conversion ratio q of the roll shifting stroke; obtaining the number i of shifting cycles; Roll stroke W i+1 , the i+1th roll shifting stroke W i+1 Meet: W i+1 =qW i , where W i is the roll shifting stroke when the number of cycles is i; obtain the roll shifting step conversion ratio p; obtain the reverse number j of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com