System for producing ribbed bar by quartered hot rolling production line

A ribbed steel bar and production system technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of high equipment investment cost, low roll utilization rate, high capital occupation rate, etc., to reduce production and operation costs, improve The effect of roll utilization rate and reduction of capital occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

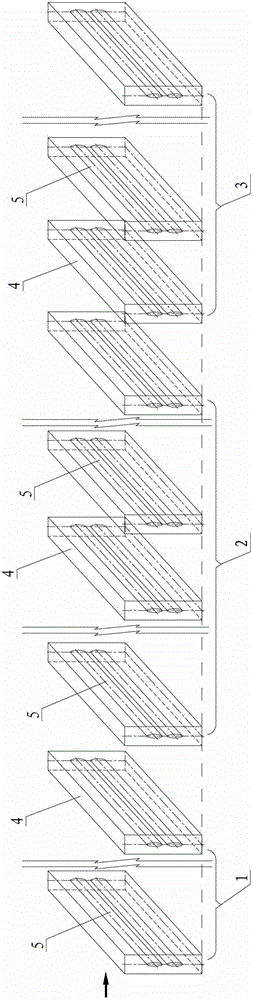

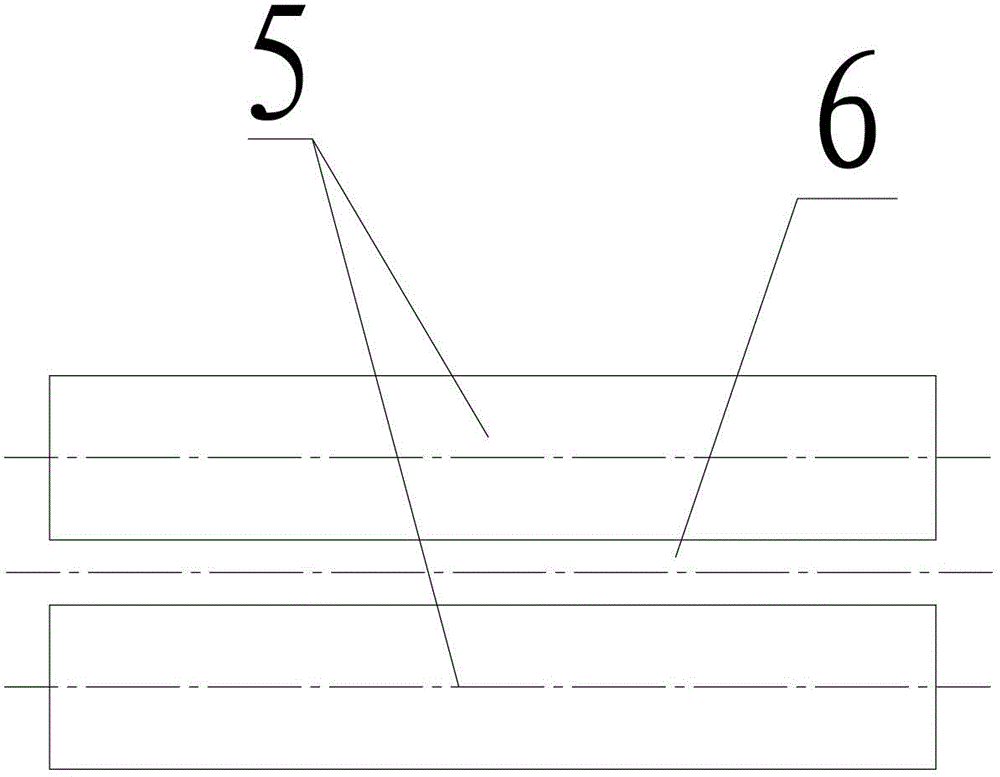

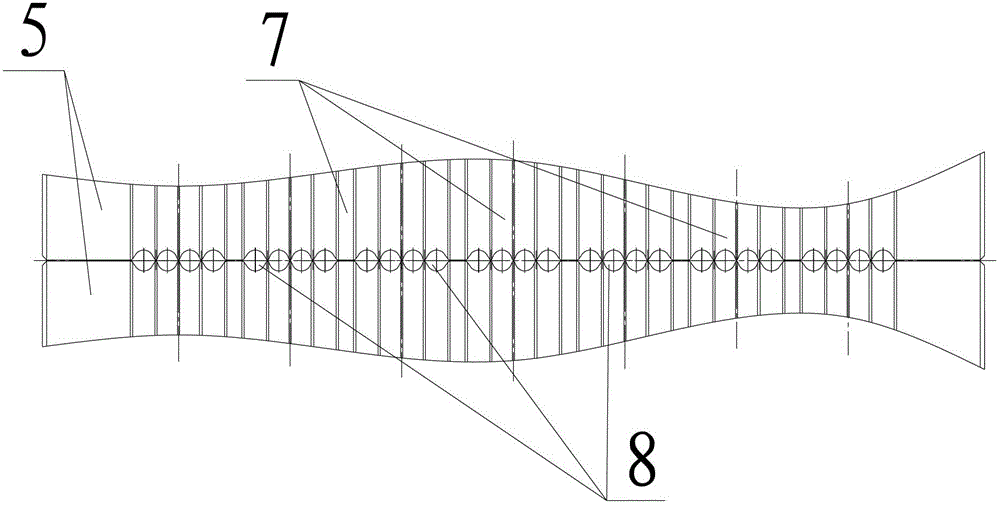

[0017] like figure 1 , figure 2 as well as image 3 Shown is a four-segmented hot rolling production system for producing ribbed steel bars in a rolling production process provided by the present invention, which has relatively low operating costs, relatively small equipment investment costs, and relatively low capital occupation. The production system for the production of ribbed steel bars by four split hot rolling comprises a rough rolling unit 1, an intermediate rolling unit 2 and a finishing rolling unit 3 arranged in sequence, and the rough rolling unit 1, the intermediate rolling unit 2 and the finishing rolling unit 3 are respectively Both comprise at least two rolling mills 4 respectively, and each rolling mill is all provided with roll 5, and the roll 5 arranged on each rolling mill 4 of rough rolling group 1 is the straight roll without rolling groove, and its rolling hole is provided by each rolling mill The radial gap 6 between two adjacent rolls 5 on 4 constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com