Fixed roll radian-change bending-point position cold-bending shaping process

A cold-formed, roll-fixed technology, applied in the field of cold-formed steel roll forming technology, can solve problems such as roll sharing design limitations, cracking, micro-cracks, etc., to reduce roll investment, reduce production costs, and form natural smoothness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

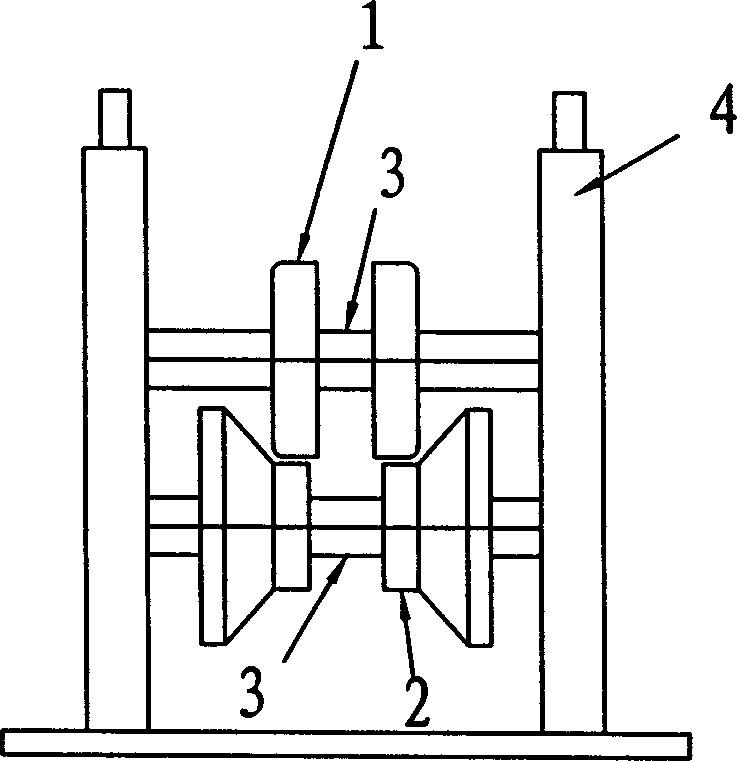

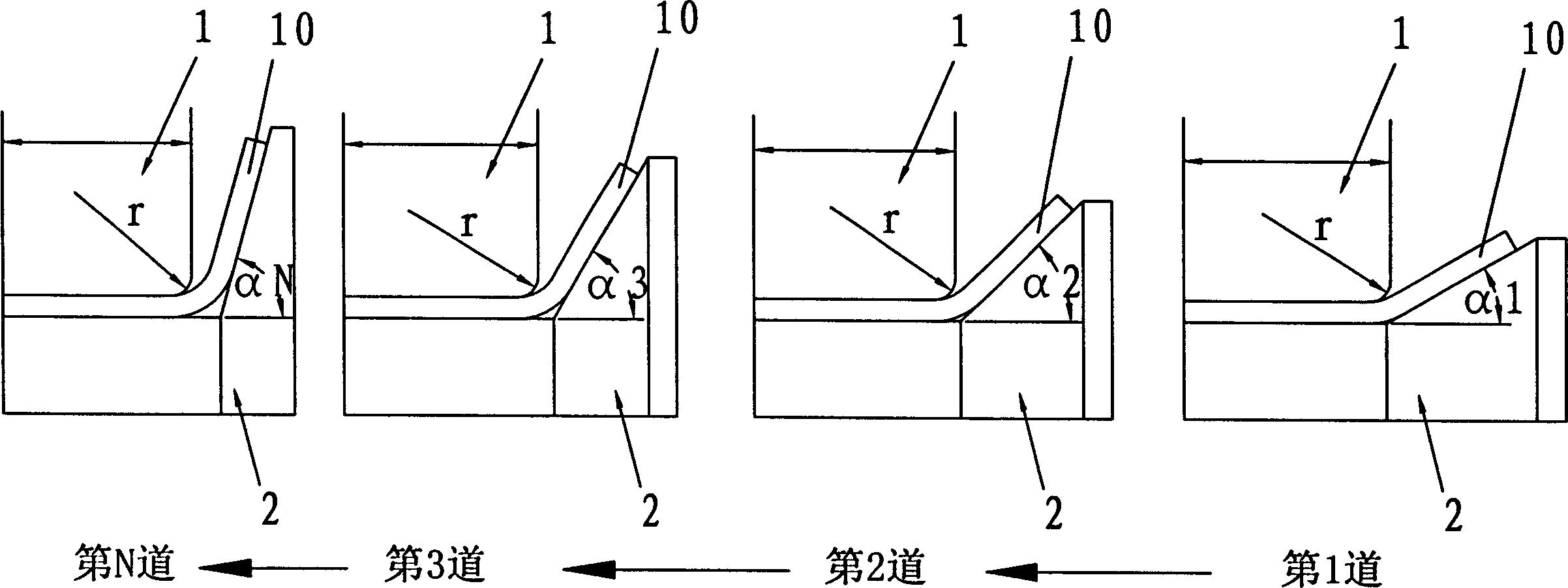

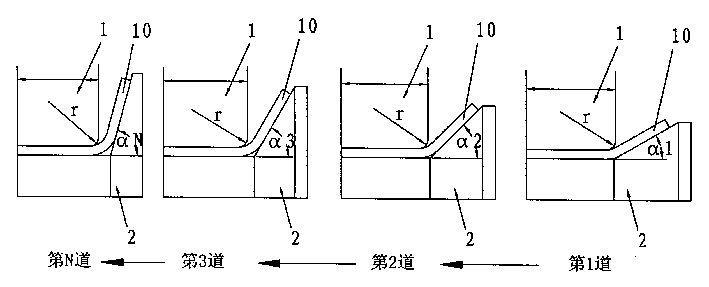

[0016] The following describes in detail the implementation of the cold-bending forming process of changing the position of the inflection point of the fixed roll radian in conjunction with the accompanying drawings. The cold-bending forming process of changing the position of the bending point with the radian of the fixed roll relates to the roll-bending process of cold-formed steel. It adopts the roll bending forming process of fixing the radian of the roll and changing the position of the bending point of the upper roll.

[0017] According to the minimum wall thickness in the product outline of the production unit, the present invention determines the bending radians of the corners of the rolls, and the upper rolls of all actual bending passes take this radian. The bending radian and forming angle of the raw material corner are determined according to the inner arc of the finished product with different wall thickness (considering the appropriate welding extrusion amount an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com