On-line roller changing device for float glass transitional roller table and roller changing method

A float glass and roller changing device technology, applied in glass production, glass manufacturing equipment, glass transportation equipment, etc., can solve the problems of difficult replacement of transition rollers, damaged rollers, affecting production, etc. The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

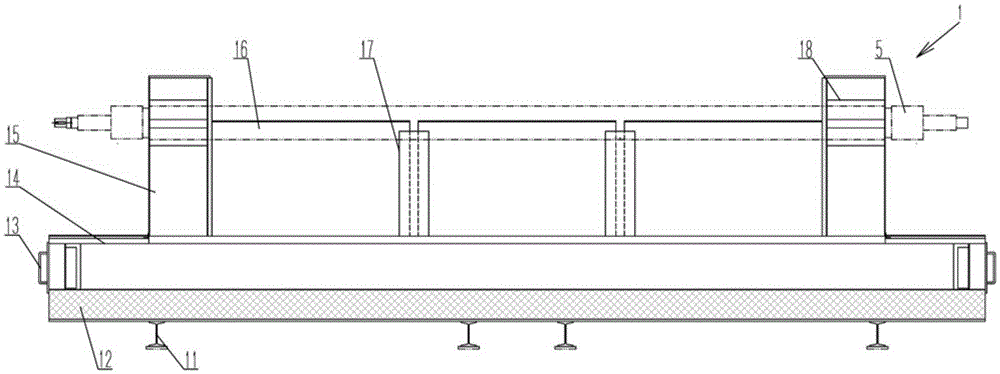

[0034] The online roll changing device and roll changing method of the float glass transition roll table of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] The float glass transition roll table is the key equipment between the tin bath equipment and the annealing kiln, and is used to introduce the glass ribbon drawn from the tin bath at about 600°C into the annealing kiln. The rollers of the transition roller table are used for a long time, and the rollers will stick to sundries, scratches, deformation, etc., which will affect the quality of the lower surface of the glass ribbon, so the rollers need to be cleaned or replaced regularly.

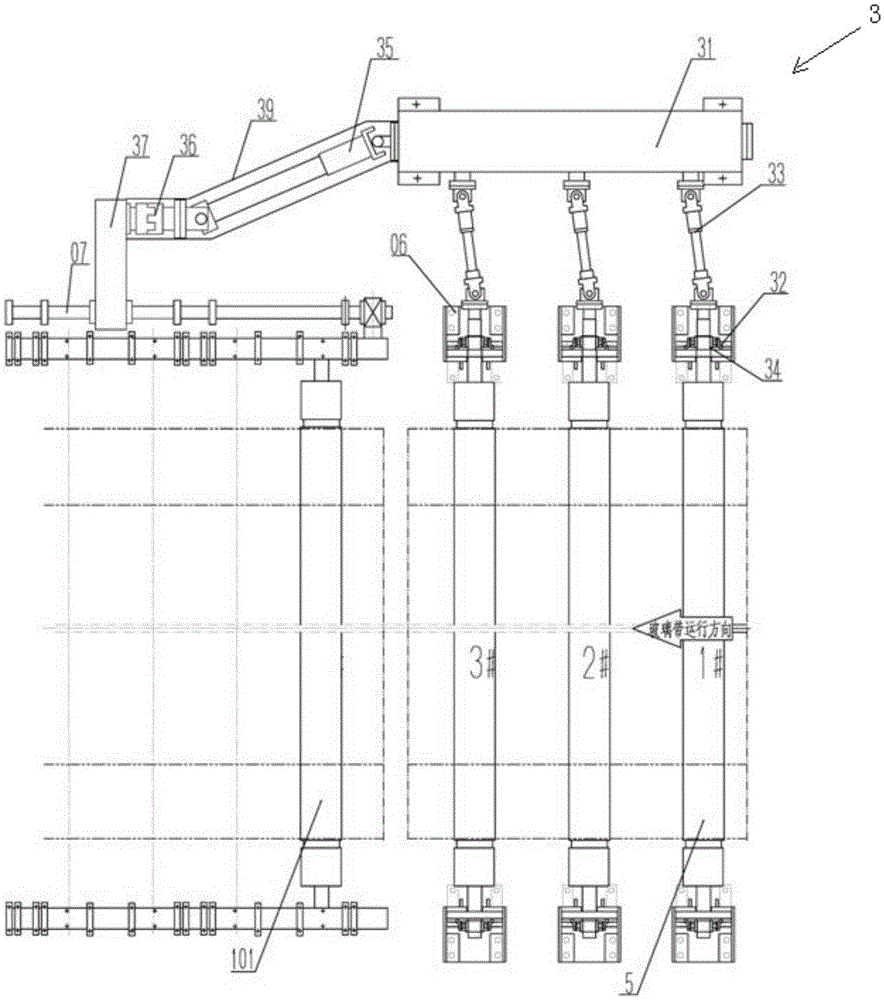

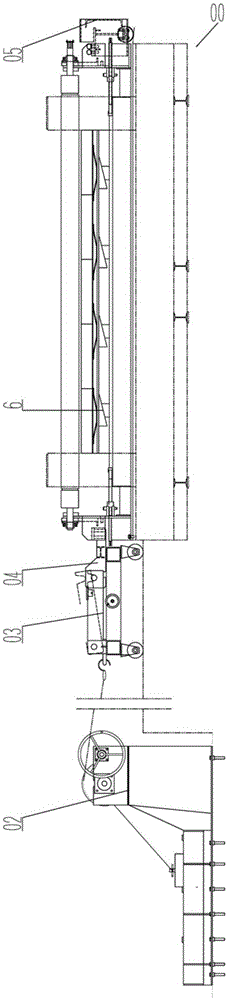

[0036] Based on the above problems, the float glass transition roll table of the present invention cooperates with the roll change device to complete the online change and save the time for roll change. Such as figure 1 As shown, the roll changing device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com