Automatic unhooking and hooking device for roll change of horizontal mill and unhooking and hooking method

A technology of horizontal rolling mill and decoupling, which is applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., and can solve problems such as potential safety hazards, prolonged roll changing time, uncontrollable roll changing state and time, etc. Achieve the effect of releasing manpower input, reducing manual operation, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

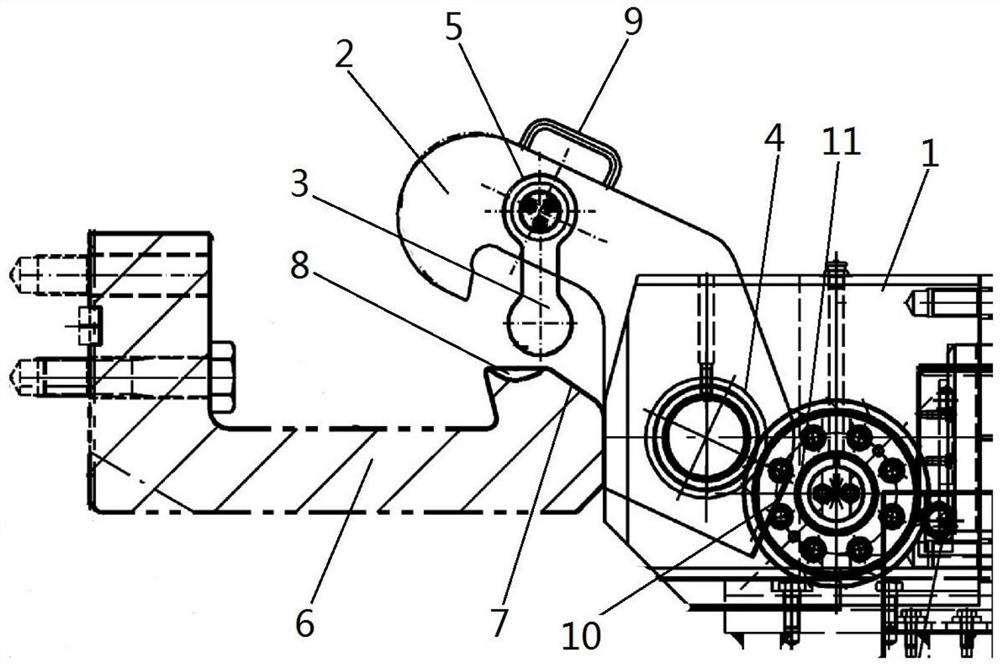

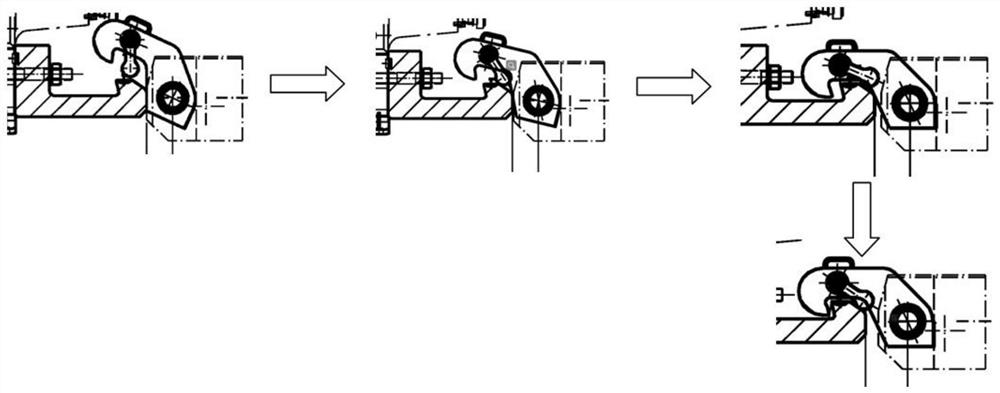

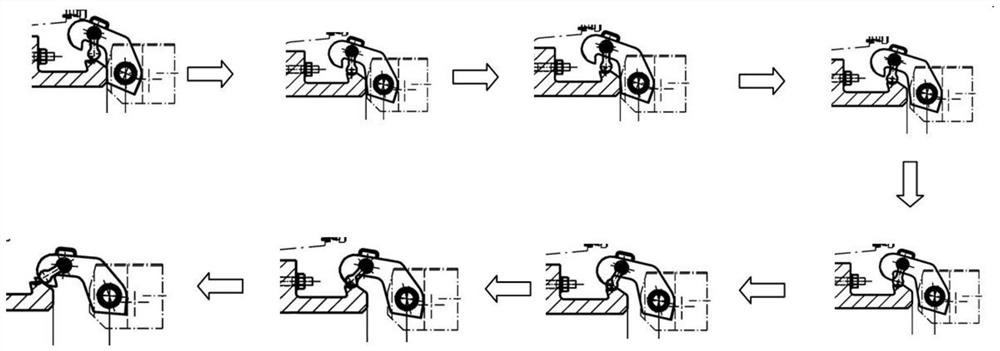

[0030] combine figure 1 , figure 2 , image 3 As shown, the embodiment of the present invention provides a device for automatic decoupling of roll changing in a horizontal rolling mill, including a roll changing trolley 1, a trolley coupler head 2, a positioning pendulum bar 3 and a roll coupler arranged at one end of a rolling mill roll 6. One end of the trolley coupler head 2 is hinged to the front end of the roller changing trolley 1 and the hinge axis is parallel to the horizontal direction and perpendicular to the front and rear direction of the roller changing trolley 1. The other end is bent downward about 45 degrees, and the other end is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com