Four-roll roll-arranging type profile steel blooming mill

A technology for blooming mills and roll matching, which is applied in the direction of metal rolling stands, metal rolling mill stands, and rolls, and can solve problems such as low production efficiency of rolling mills, affecting steel rolling production, and increasing energy consumption, so as to save roll costs and improve Utilization rate and the effect of saving roll changing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the embodiments.

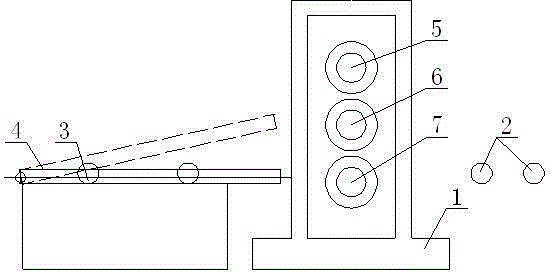

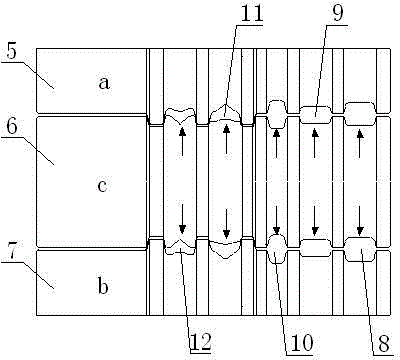

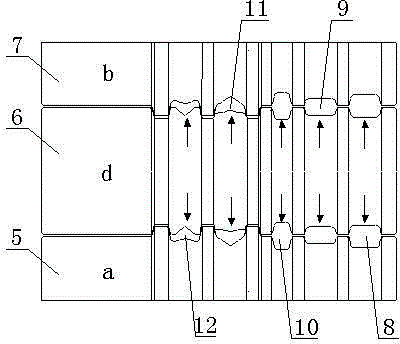

[0016] Depend on Figures 1 to 4 It can be seen that the four-high profiled steel blooming mill includes a rolling mill stand 1, a front working roll table 2, a rear working roll table 3, a lifting platform 4 and their respective connected transmission mechanisms arranged before and after the stand. The upper roll a5 and the lower roll b7 are arranged on the stand of the rolling mill. The lengths and diameters of the two rolls are the same, and 5-7 rolling grooves are set on the roll surface, and their positions and shapes are exactly the same; the middle roll is equipped with at least two structures. For the same middle roll c and middle roll d6, the grooves on the middle roll correspond to the grooves of the upper and lower rolls. According to the first roll pattern of upper roll a, middle roll c and lower roll b, they are fixed from top to bottom. On the rolling mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com