Rotating disc type chip feeding device and core feeding method

A carousel type, chip technology, applied in the direction of rotary conveyor, transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity of operators, small number of materials, poor safety, etc., to achieve compact structure and labor intensity. Small, safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

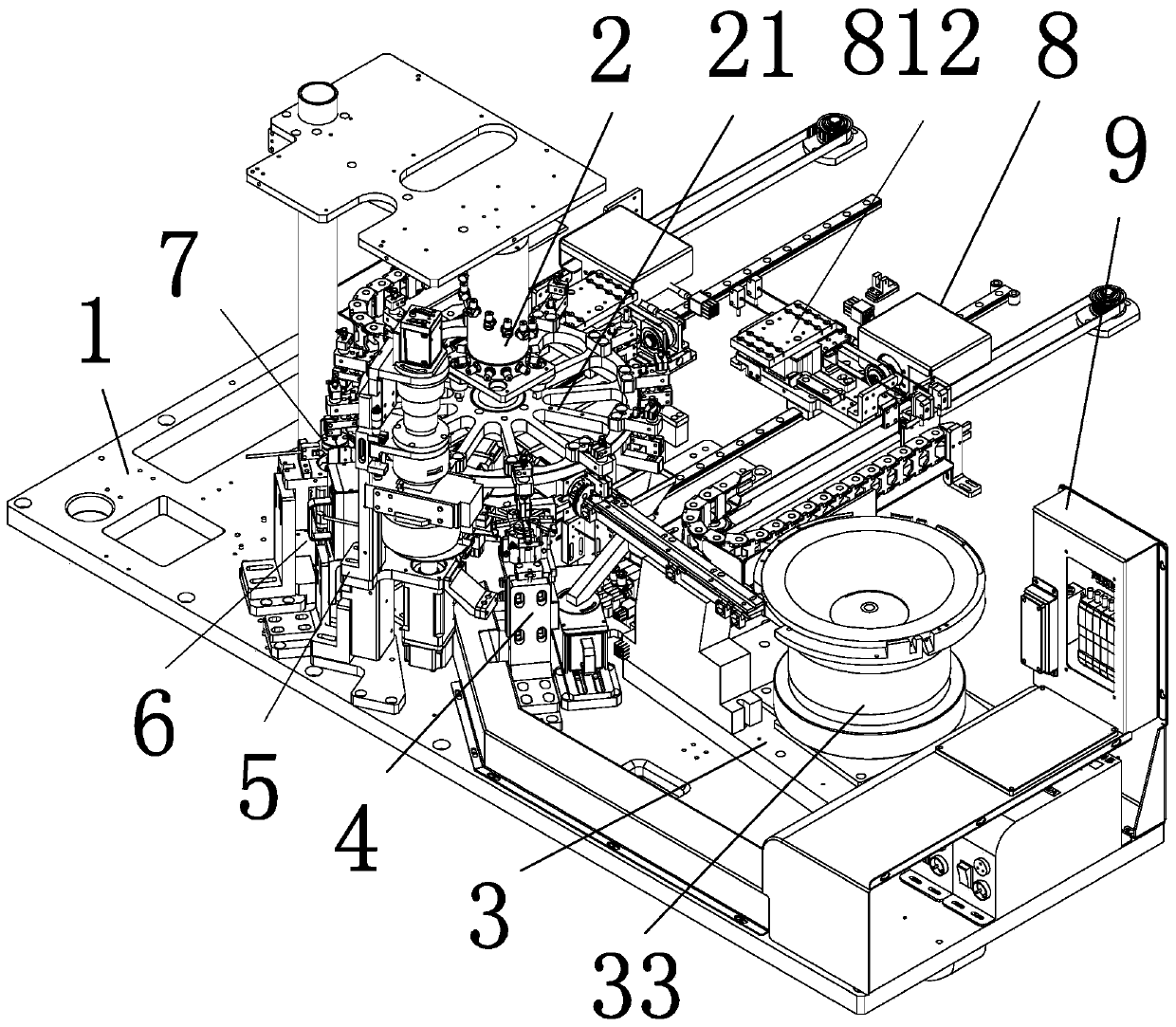

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

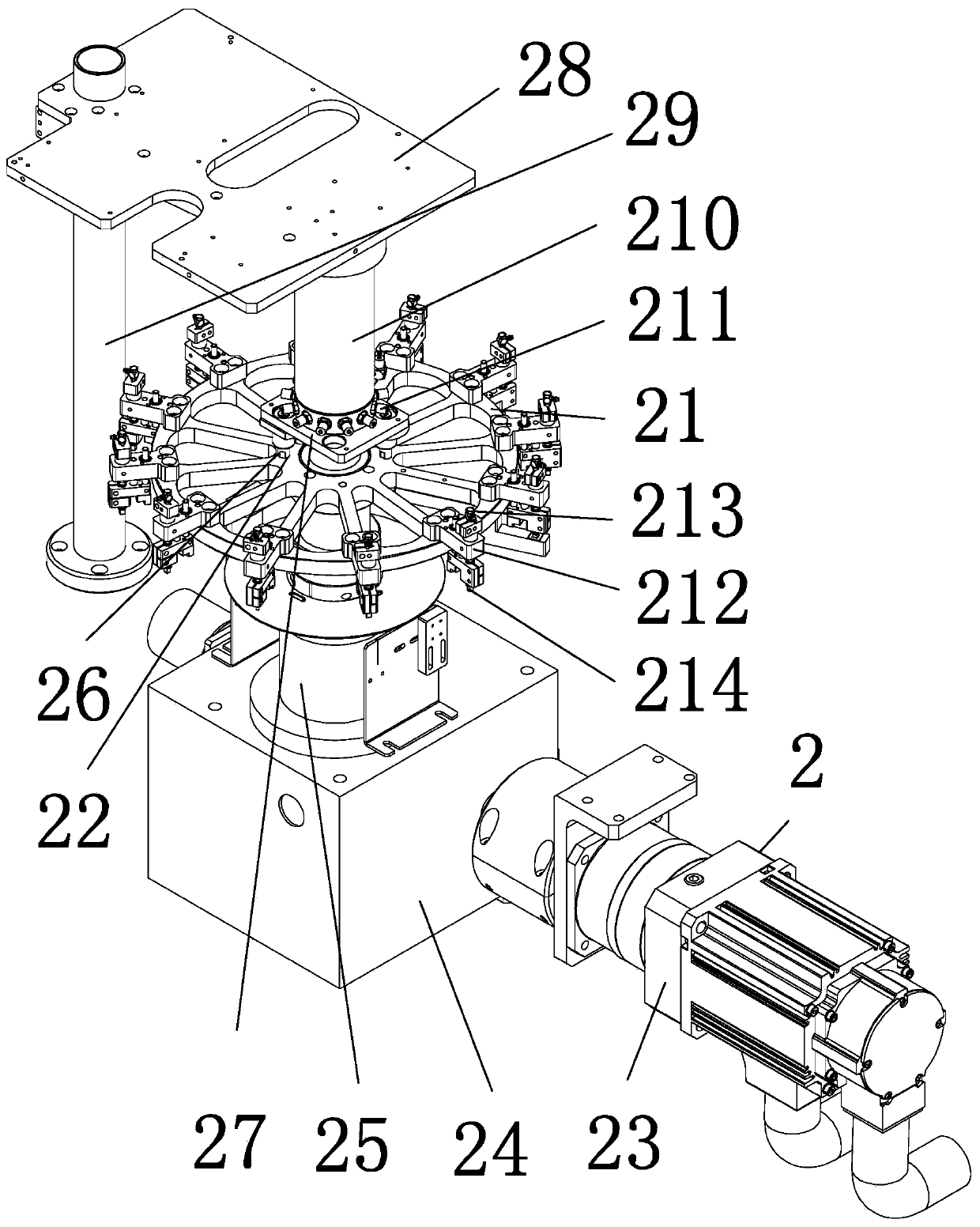

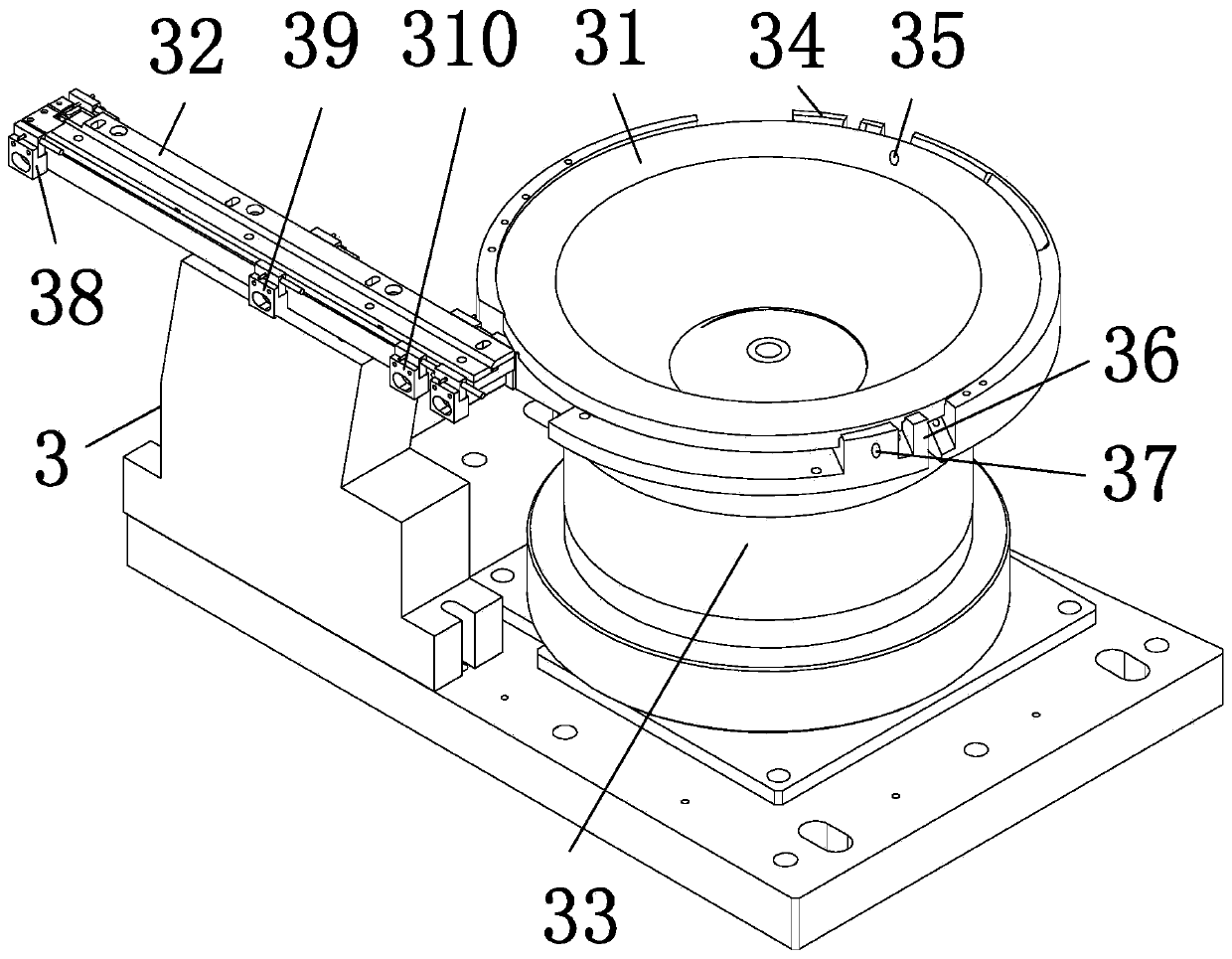

[0026] as attached figure 1 to attach Figure 8 Shown: a turntable type chip feeding device, comprising: a base 1, a turntable indexing device 2 provided on the base 1 and provided with a turntable 21, a vibrating fixed surface discharge device 3 distributed along the circumference of the turntable 21, Chip positioning device 4 , chip marking visual inspection system 5 , defective chip storage device 6 , chip rotating device 7 , and shuttle conveying device 8 .

[0027] Described turntable type indexing device 2 comprises: two guide holes 22 that turntable 21 is provided with, is provided with turntable motor 23 and the lift type cam indexer 24 that is screwed with base 1 upper end, two ends and lift type cam indexer 24 The output shaft and the lower end of the turntable 21 correspond to the turntable adapter column 25 that is screwed one by one, and there are gas jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com