Ceramic pipe grinder for food grinding processing

A technology of grinding processing and ceramic pipes, which is applied in the fields of application, food science, cocoa, etc., can solve the problems of intermittent air grinding and instantaneous air grinding, large material discharge resistance, poor impact resistance, etc., to overcome brittleness, overcome Poor impact resistance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

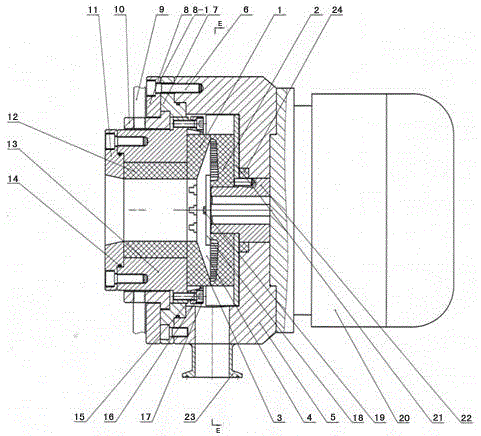

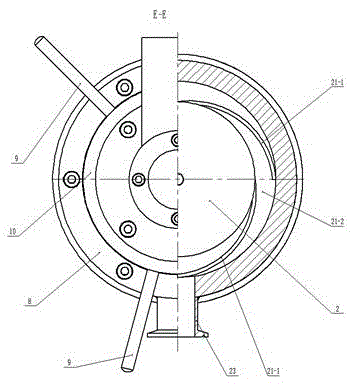

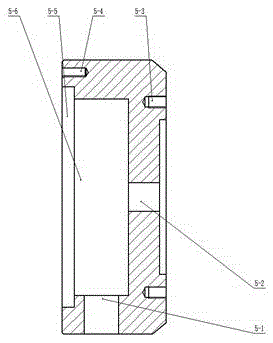

[0096] like figure 1 , figure 2 , image 3 ,picture, Figure 5 and Image 6As shown, the present invention includes a housing 5, the housing 5 is a horizontal cylindrical housing, and a discharge hole 5-1, a motor shaft sleeve mounting hole 5-1 are processed on the horizontal cylindrical housing 5. 2. Motor flange connection hole 5-3, first threaded hole 5-4, casing wall groove 5-5 and grinding disc installation cavity 5-6, grinding disc installation cavity 5-6 is for installing static grinding disc 1 and moving grinding disc 2, the motor 20 is installed on the right side of the housing 5, the motor shaft sleeve 22 is installed on the output shaft of the motor 20, and the motor shaft stretched into the grinding disc installation cavity 5-6 through the motor shaft sleeve installation hole 5-2 Install the movable grinding disc 2 on the cover 22, fasten the left end surface of the movable grinding disc 2 with fastening screws 19 and gaskets 18, install the static grinding d...

specific Embodiment approach 2

[0099] It is the same as the specific embodiment 1, except that the static grinding disc 1 is described in detail.

[0100] like Figure 7 , Figure 8 and Figure 9 As shown, the substrate of the static grinding disc 1 of the present invention is a cylinder with a thickness of 15 mm to 35 mm and an outer diameter of 60 mm to 500 mm, but not limited to 500 mm. The center of the static grinding disc 1 is provided with a feed hole 1-1, and the feed hole 1 The diameter of -1 is 20-80mm, so that the material can be fed from the central feeding port of the static grinding disc 1, and the food material can be diffused to the surroundings, which overcomes the problem that the eccentric feeding port feeds unevenly in one direction, and the food material cannot enter the center of the grinding disc. According to different food materials and different purposes, different static grinding disc thicknesses, static grinding disc outer diameters and static grinding disc feeding hole diamete...

specific Embodiment approach 3

[0102] It is the same as the specific embodiment 1, the difference is that the movable grinding table 2 will be described in detail.

[0103] like Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, the base body of the movable grinding disc 2 of the present invention is a cylinder with a thickness of 15 mm to 35 mm and an outer diameter of 60 mm to 500 mm, but not limited to 500 mm. The center of the movable grinding disc 2 is provided with a motor shaft mounting hole 2-1 and a fixed nut installation Plane 2-8, the diameter of the mounting hole 2-1 matches the diameter of the output shaft of the motor used for its installation, the back of the moving grinding disc 2 is a light plane 2-3, and a weight-reducing groove is arranged on the light plane 2-3 2-4, the working face of the movable grinding disc 2 is provided with a peripheral grinding plane 2-2 of 3-10mm wide along the outer diameter circumference, and the peripheral grinding plane 2-2 of the dynamic grindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com