Patents

Literature

94results about How to "Less plastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

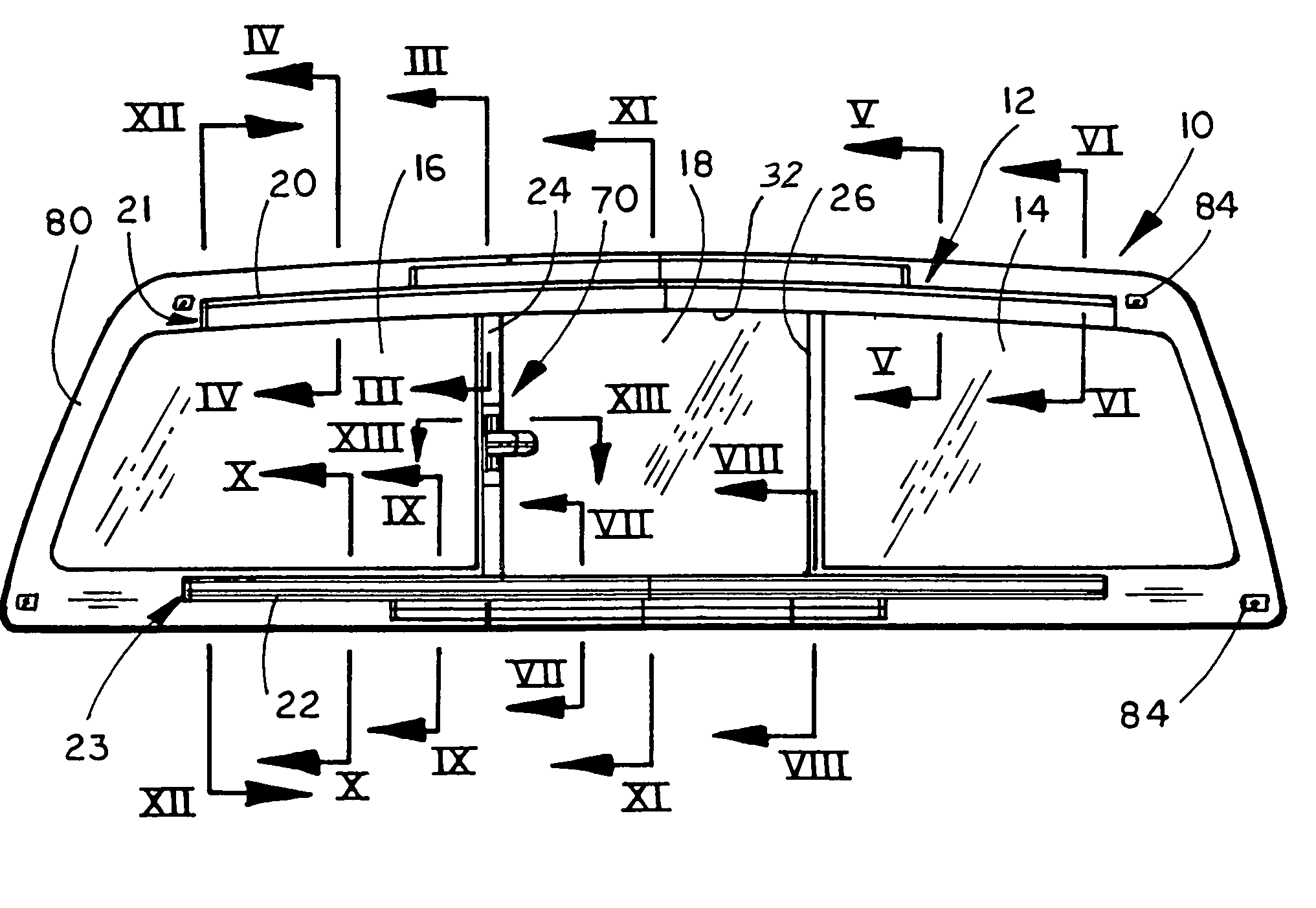

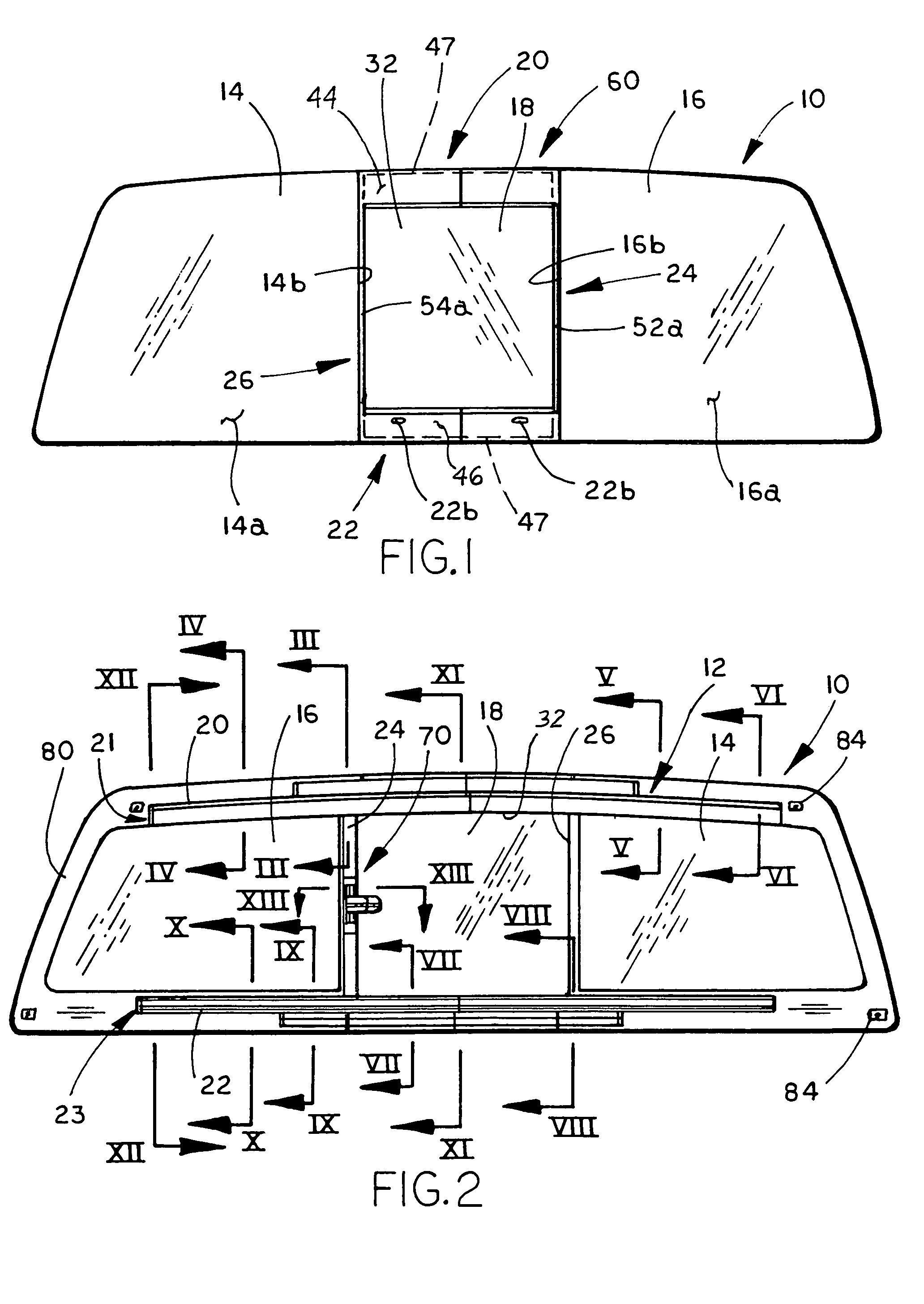

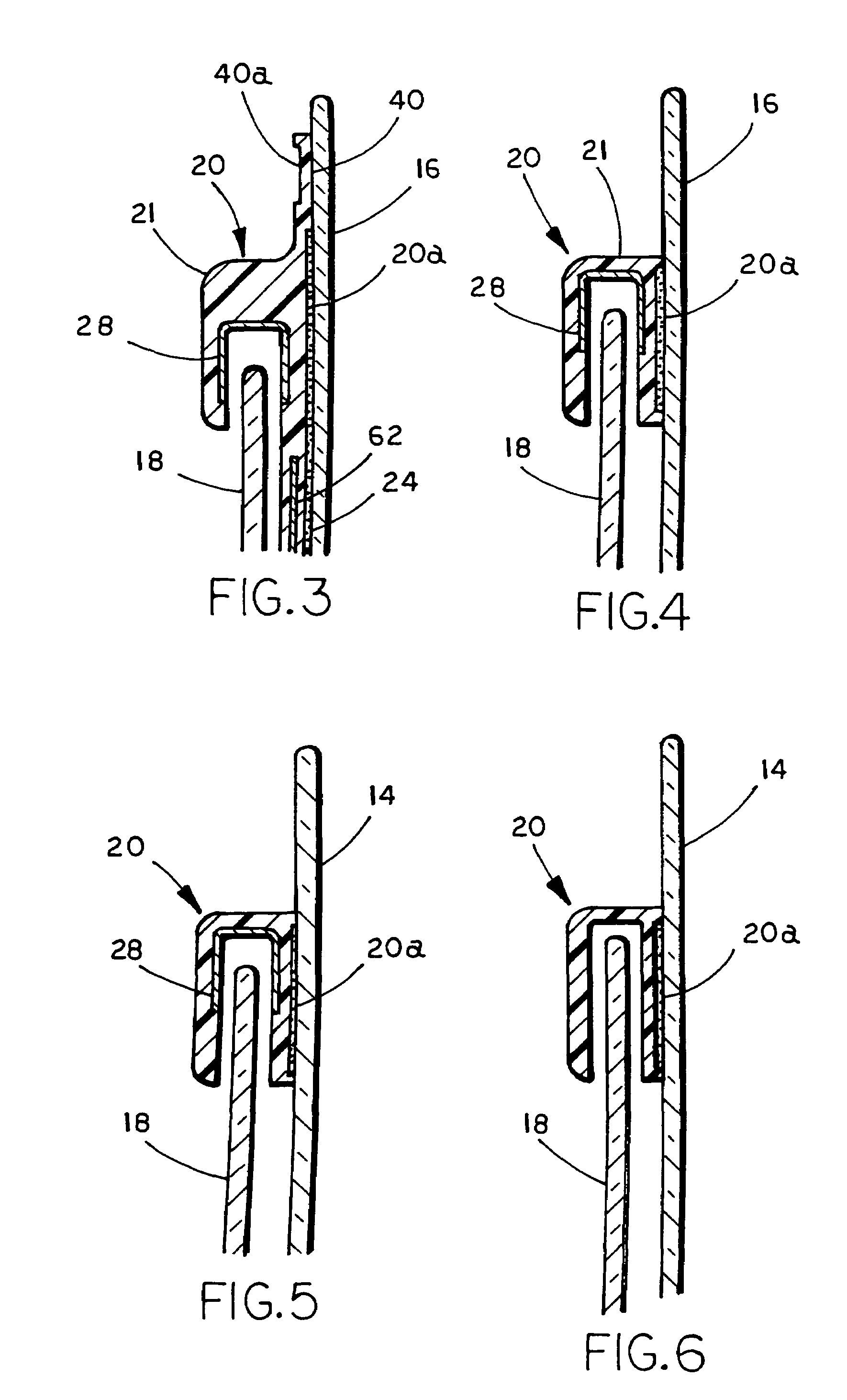

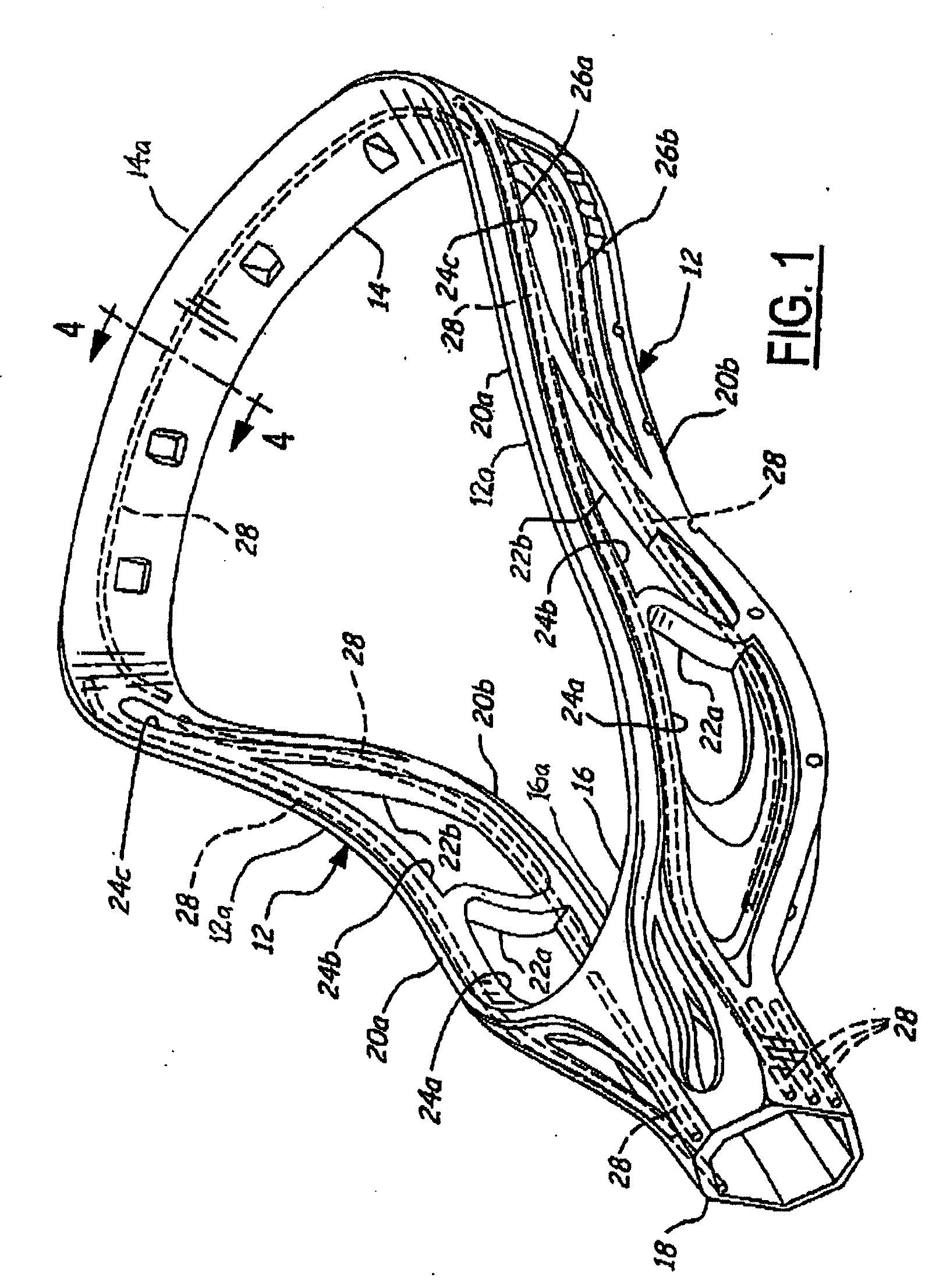

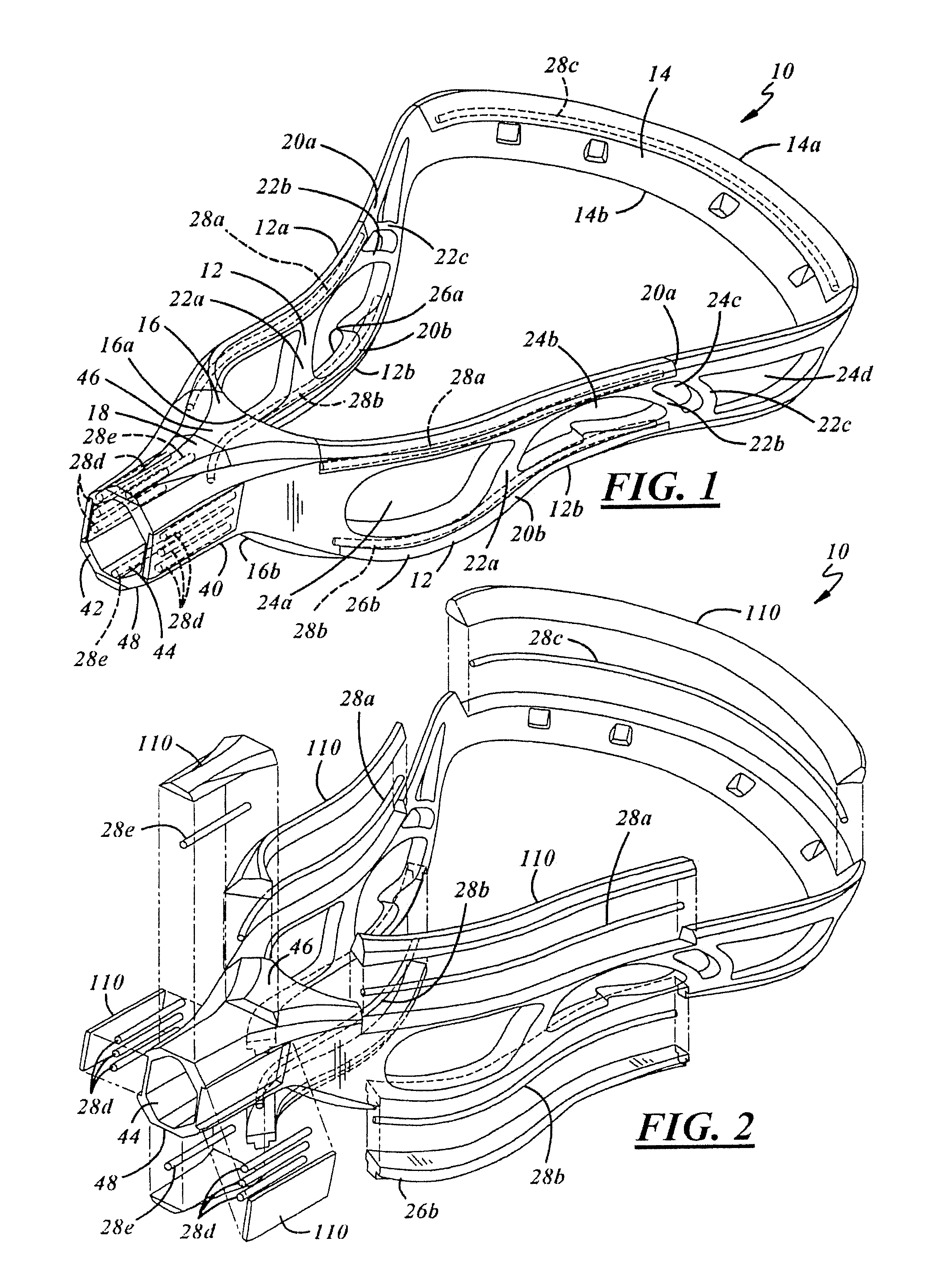

Horizontal slider window assembly

A vehicular rear window assembly for a vehicle comprises a first fixed pane, a second fixed pane, and a sliding pane, which is supported for horizontal movement between open and closed positions. The window assembly includes a support system with an upper horizontal member, a lower horizontal member, and a pair of spaced apart vertical members, which interconnect the upper horizontal member and the lower horizontal member to define a central opening. The fixed panes adhesively mount to the upper and lower horizontal members. The vertical members have exposed exterior surfaces that are preferably generally flush with the exterior surface of the fixed panes.

Owner:DONNELLY CORP

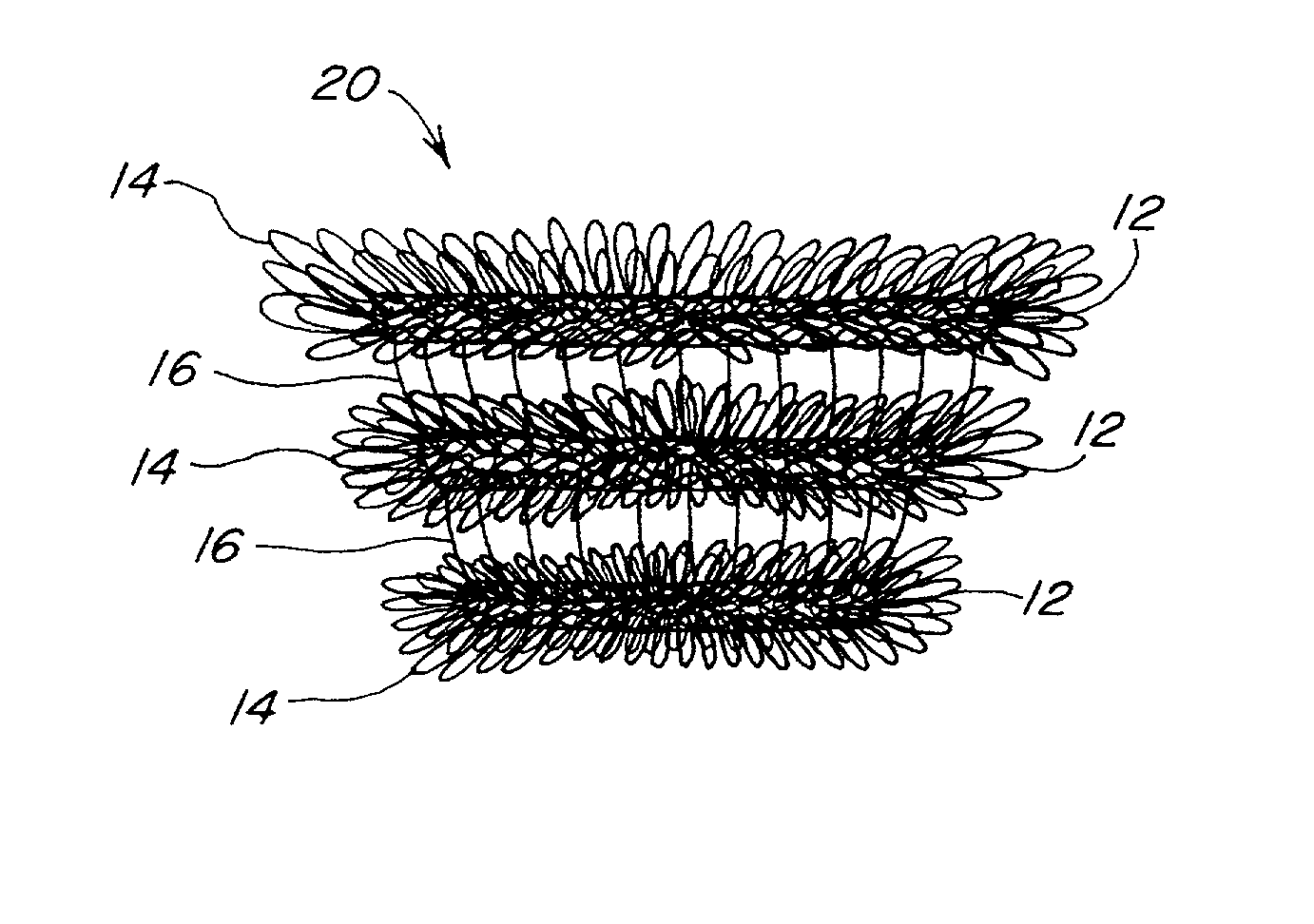

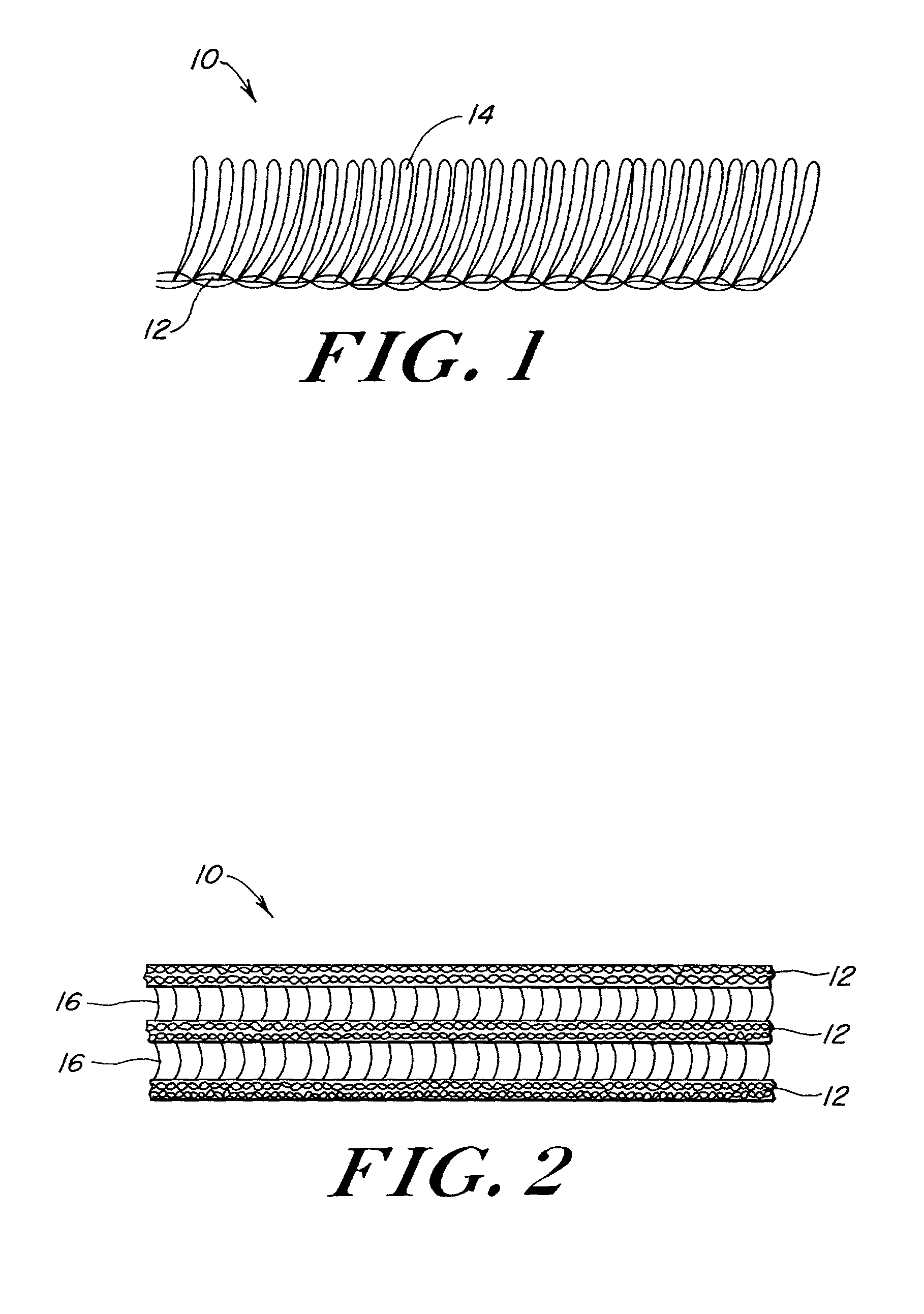

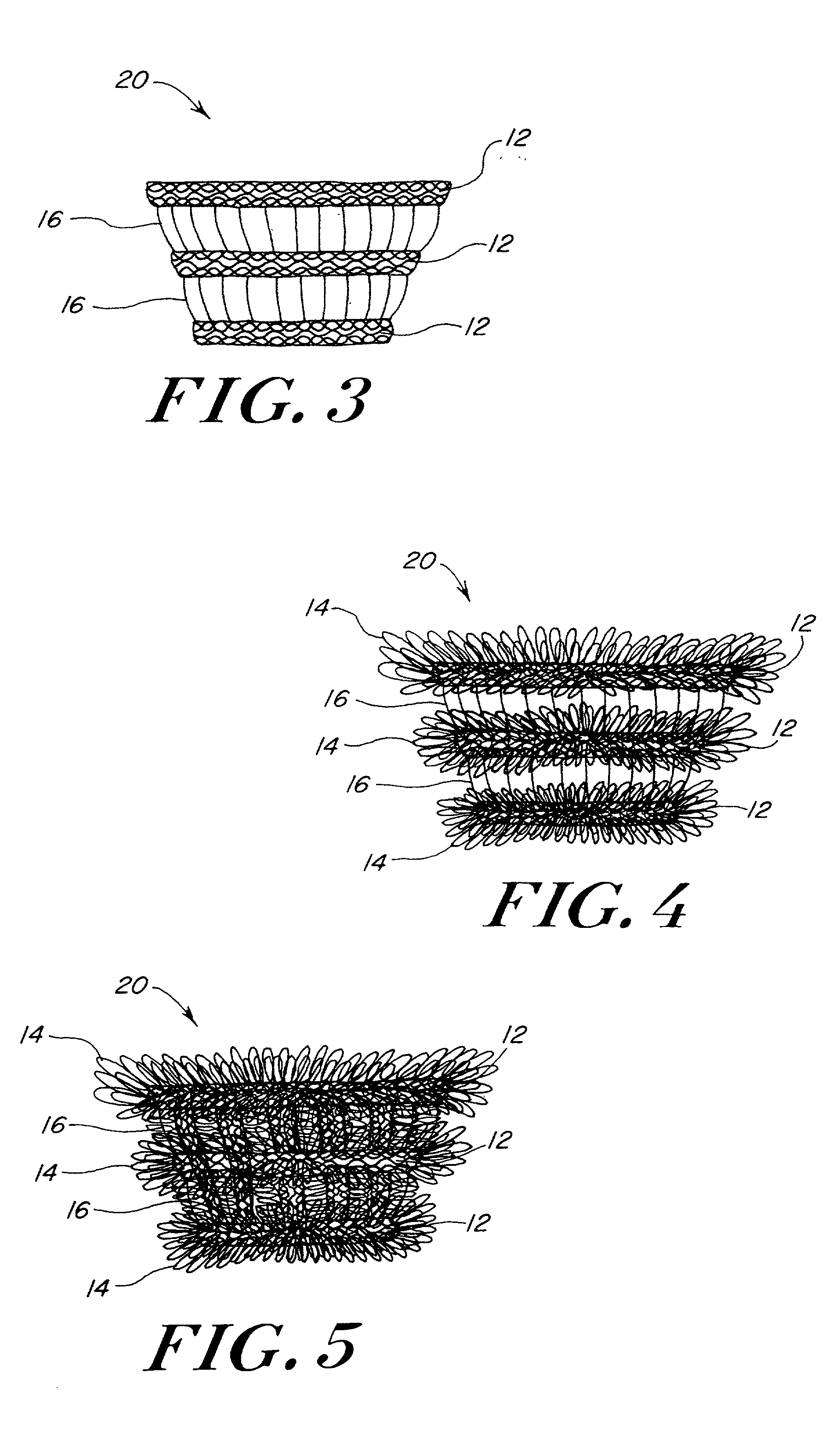

Pile mesh prosthesis

InactiveUS20020116070A1Add support structurePromoting rapid tissue in-growthWeft knittingWarp knittingRepair tissueProsthesis

A method and apparatus relating to a biocompatible soft tissue implant is disclosed. The implant, in the form of a prosthesis, is constructed of a knitted pile mesh material arranged into either a 3-dimensional structure or a planar shape or structure. The material or fabric includes a plurality of filament extensions projecting outwardly therefrom. The filament extensions can be radially projecting looping filaments from one or more rows of the knitted pile mesh material. The combination of the filament extensions with the 3-dimensional structure results in the biocompatible implant having a structural resistance to hinder anticipated crushing forces applied to the implant, and also provide a suitable 3-dimensional structure for promoting rapid tissue in-growth to anchor such implant without migration and strengthen the repaired tissue area.

Owner:ATRIUM MEDICAL

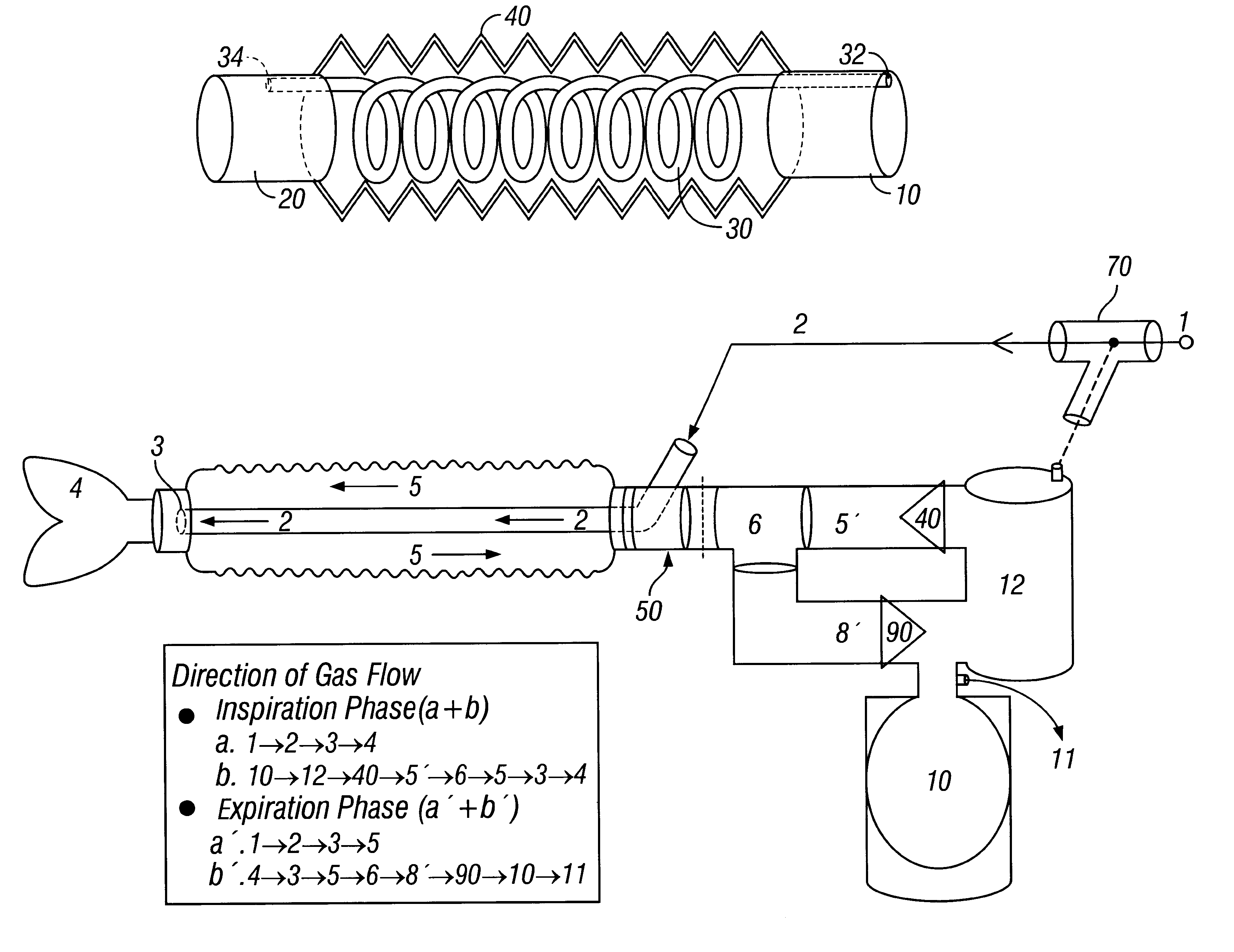

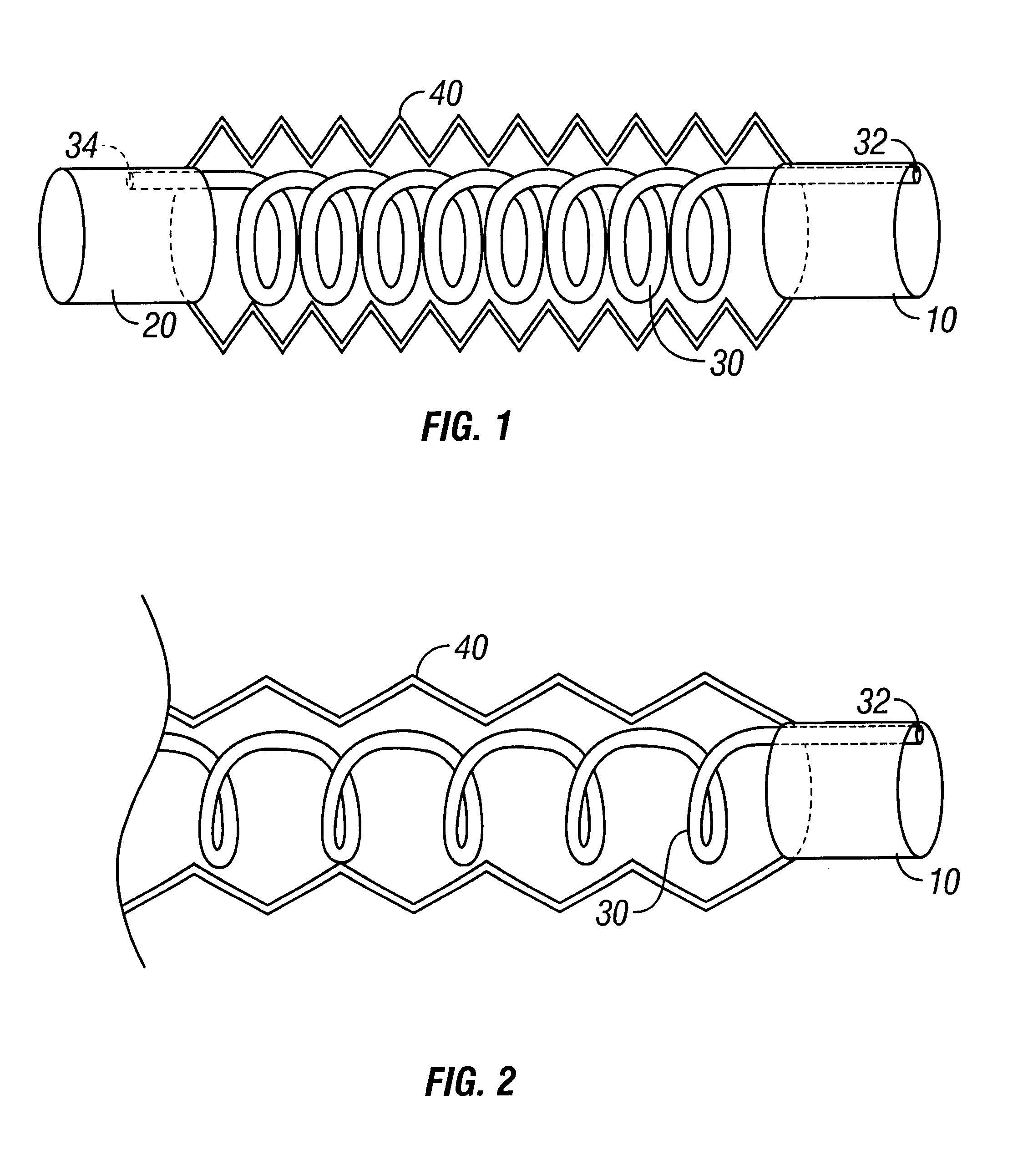

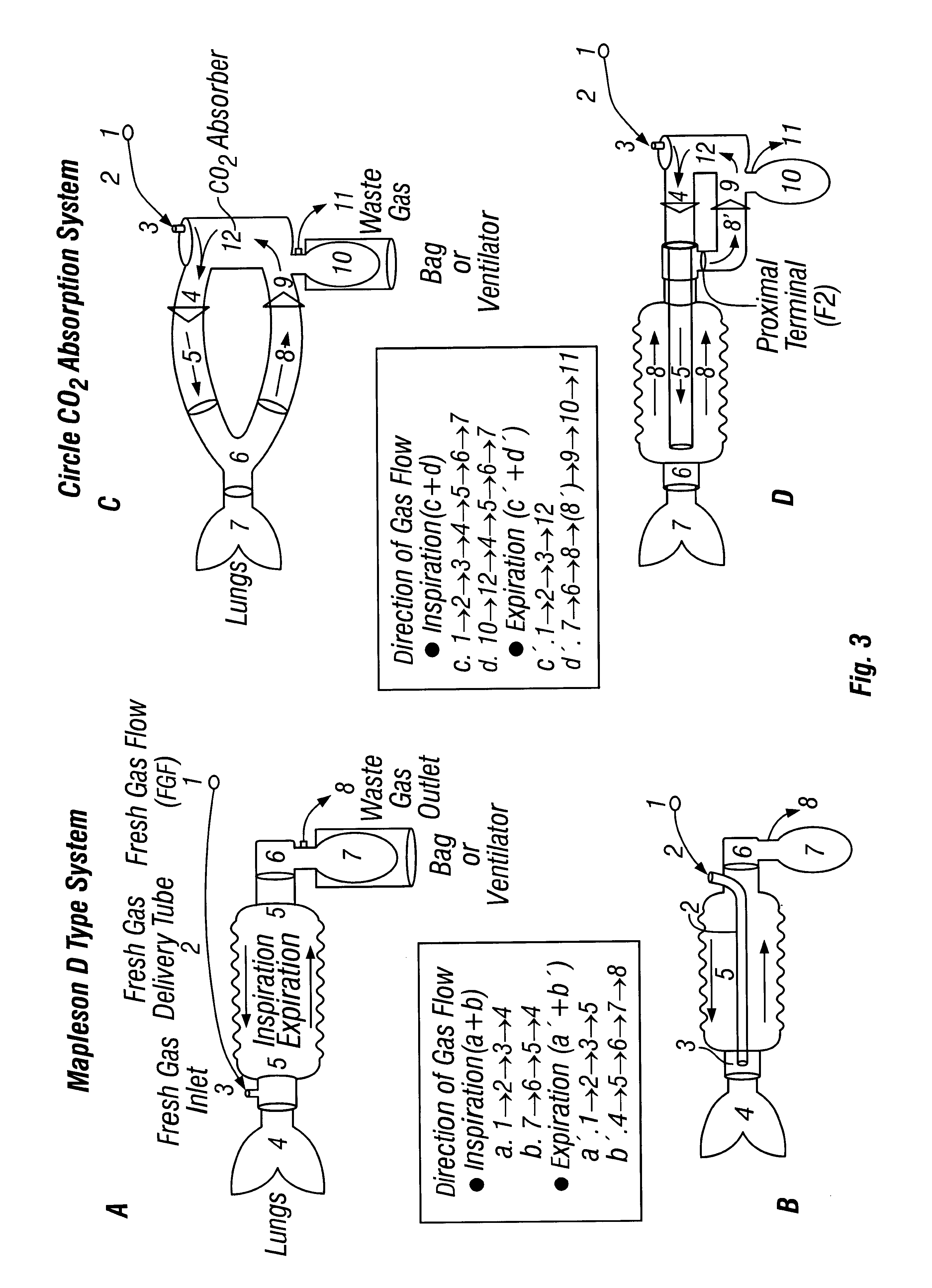

Breathing circuits having unconventional respiratory conduits and systems and methods for optimizing utilization of fresh gases

InactiveUS6874500B2Regulate securityOptimizing the utilization of anesthetic gasesRespiratorsSurgeryBreathing gasCatheter

A breathing circuit comprising first and second conduits, wherein at least one of the conduits is a non-conventional conduit. In an embodiment, a multilumen unilimb breathing circuit has first and second conduits, wherein when the proximal ends of said first and second conduits are each connected to an inlet and outlet fitting, respectively, movement of the distal end of the first conduit causes a corresponding movement of the distal end of the second conduit. In an embodiment, at least one of said conduits is coiled. In another embodiment, a coiled conduit is contained within an outer flexible conduit that is axially extendable and compressible, forming a unilimb multilumen respiratory circuit. The outer flexible conduit may be pleated to provide for non-rebounding axial extension and contraction. The multilumen respiratory circuit can provide a variable rebreathing volume. In an embodiment, at least one tube in a multilumen respiratory conduit is radially collapsible and radially expandable to a maximum radius for carrying respiratory gases to and from a patient. The methods and systems can be used to administer anesthesia and for other purposes.

Owner:AMBU AS

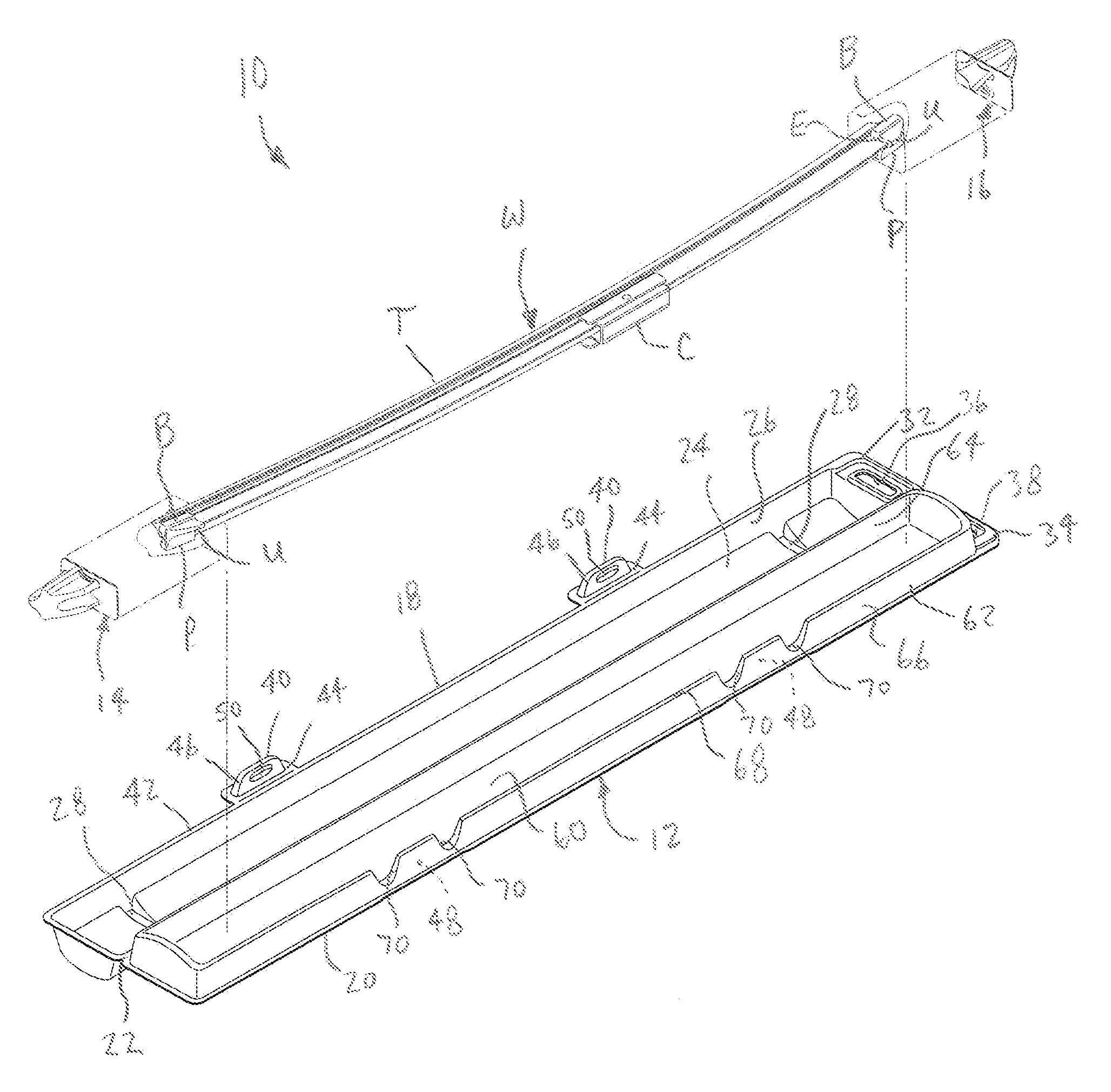

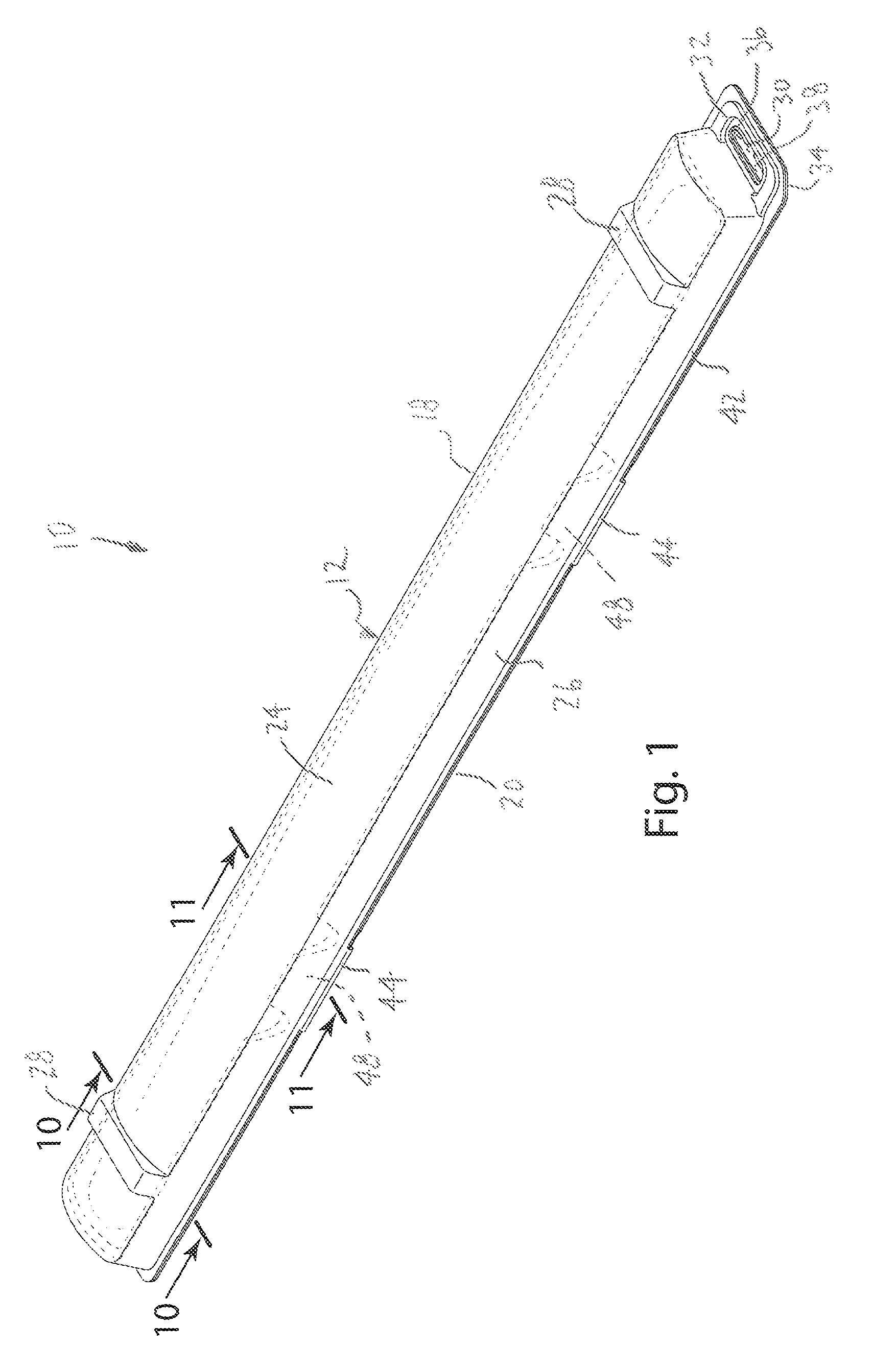

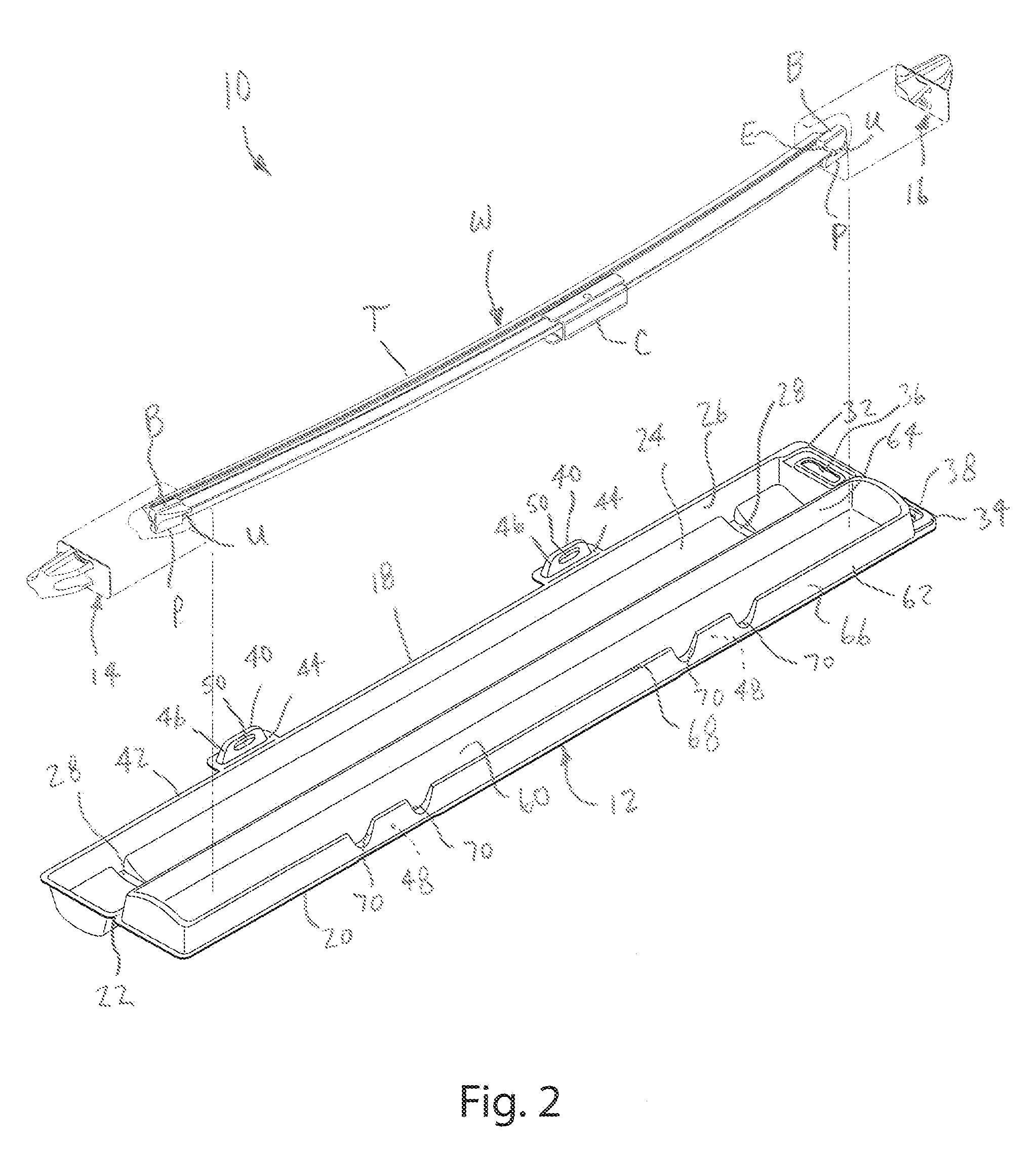

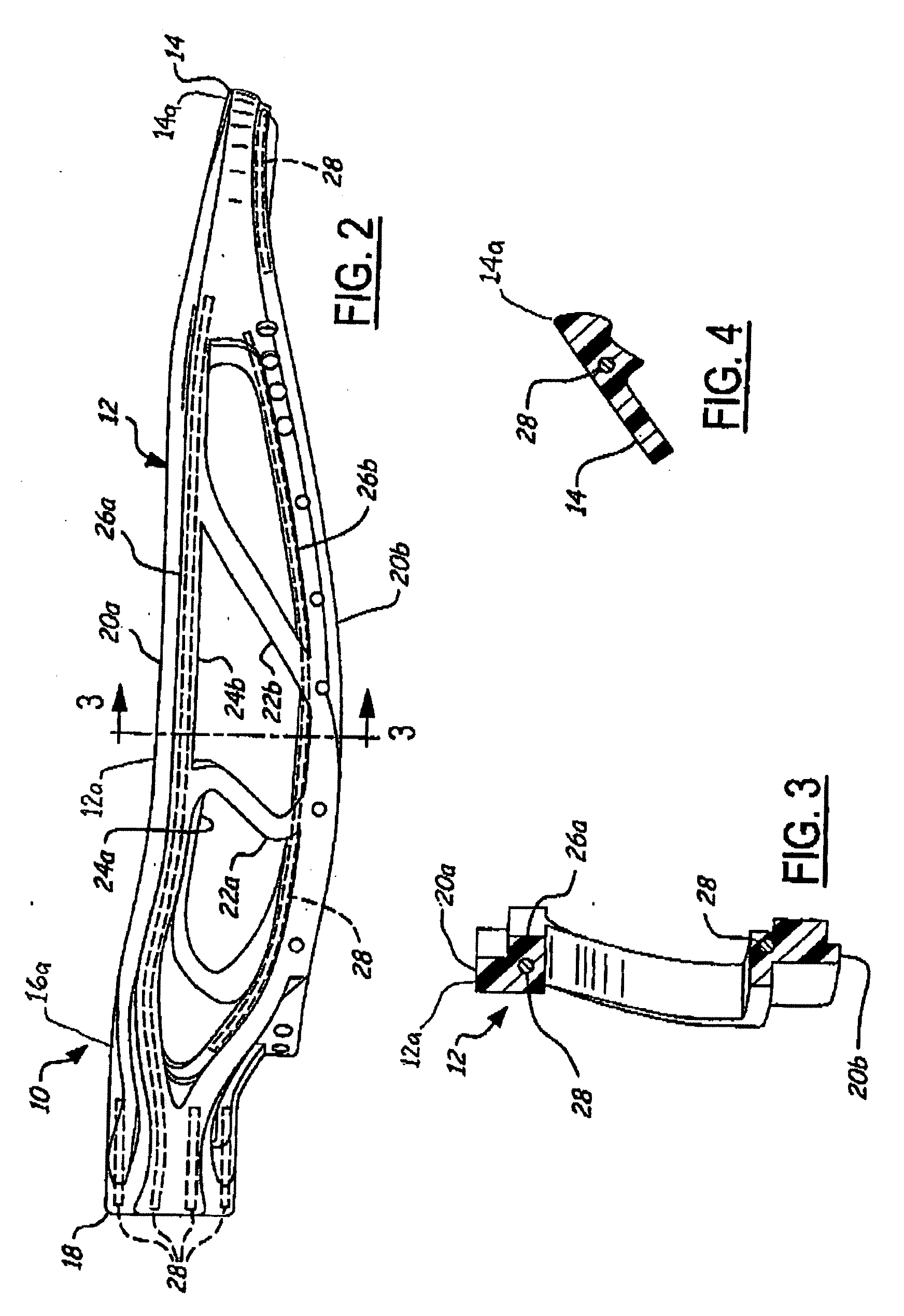

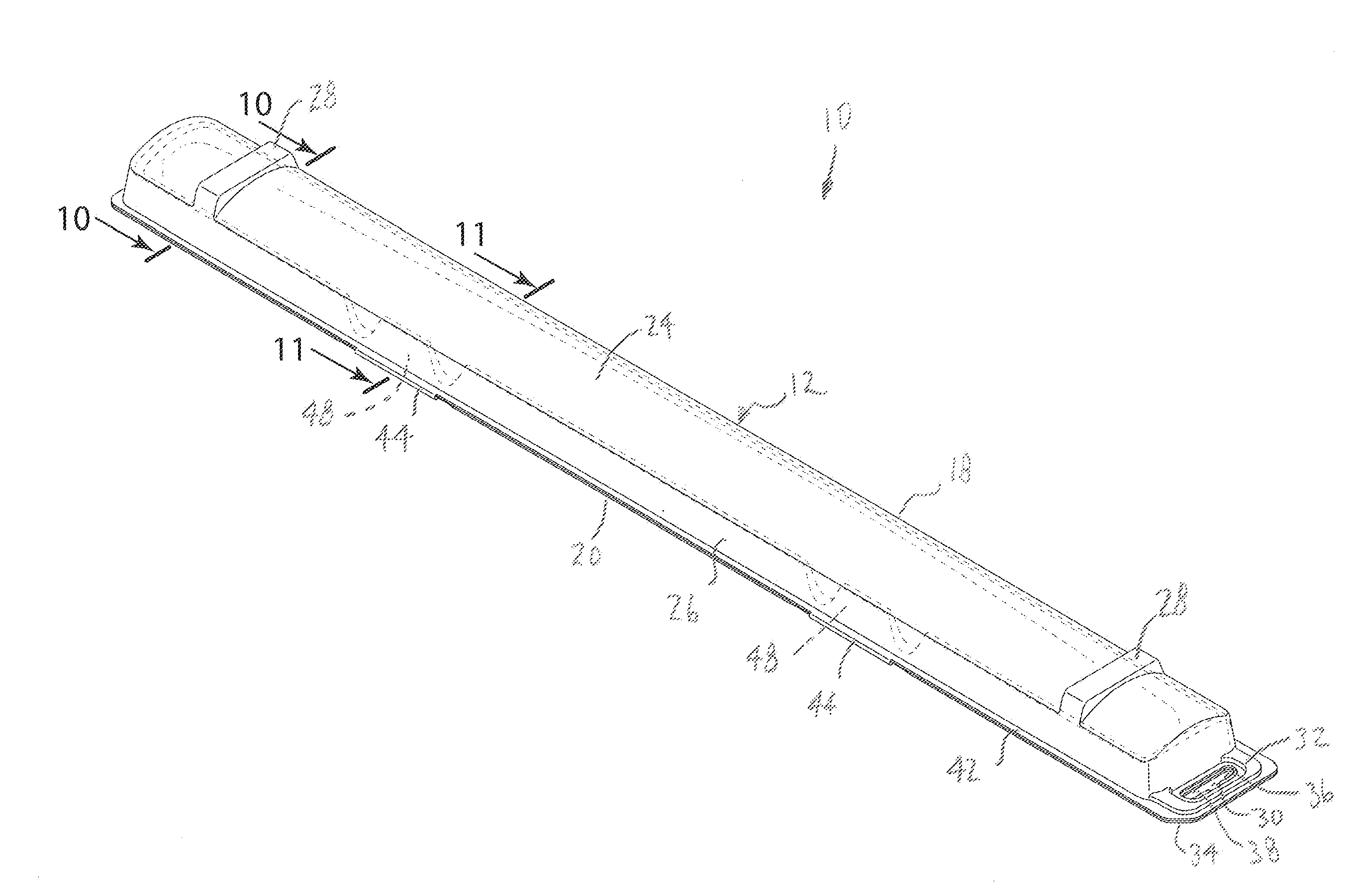

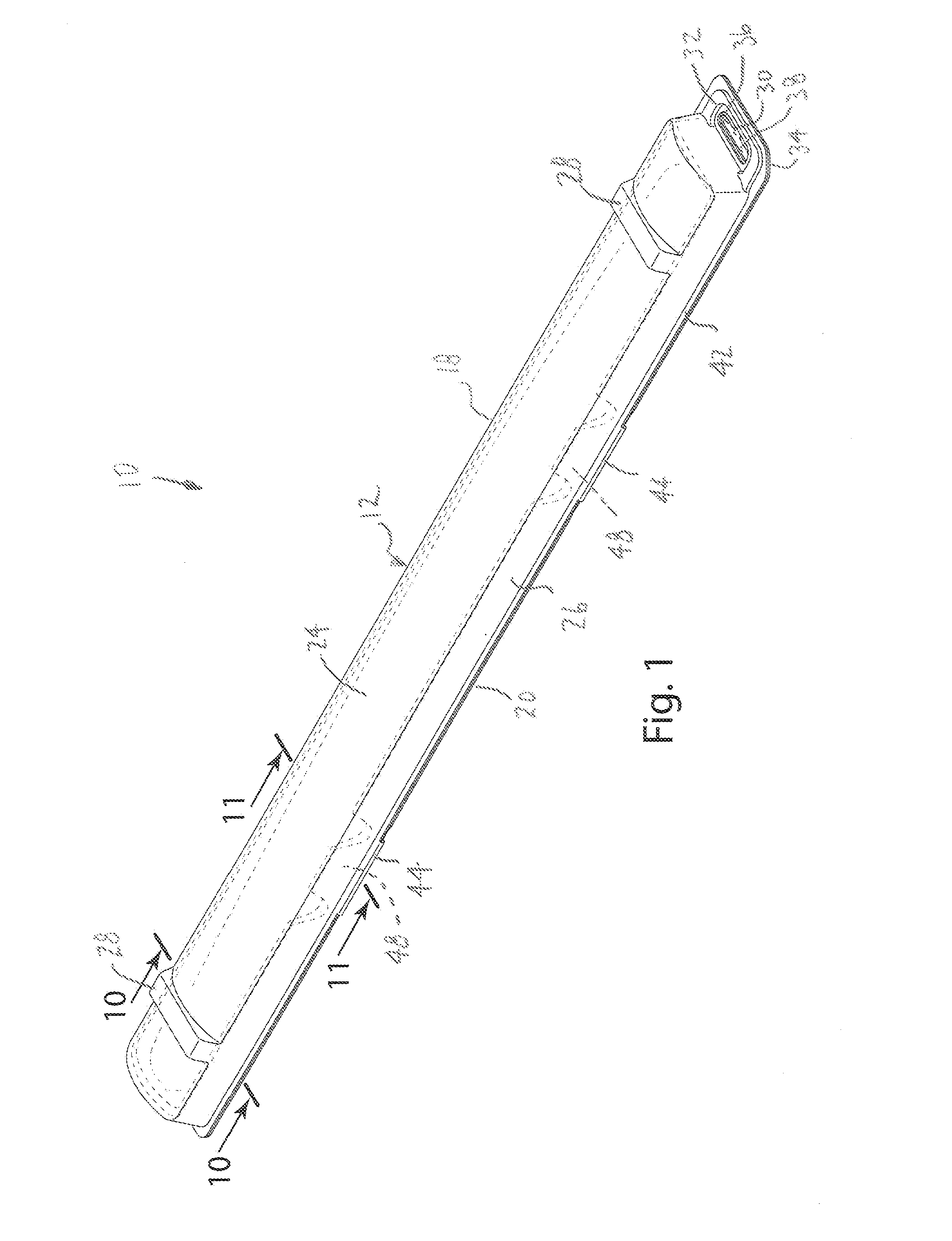

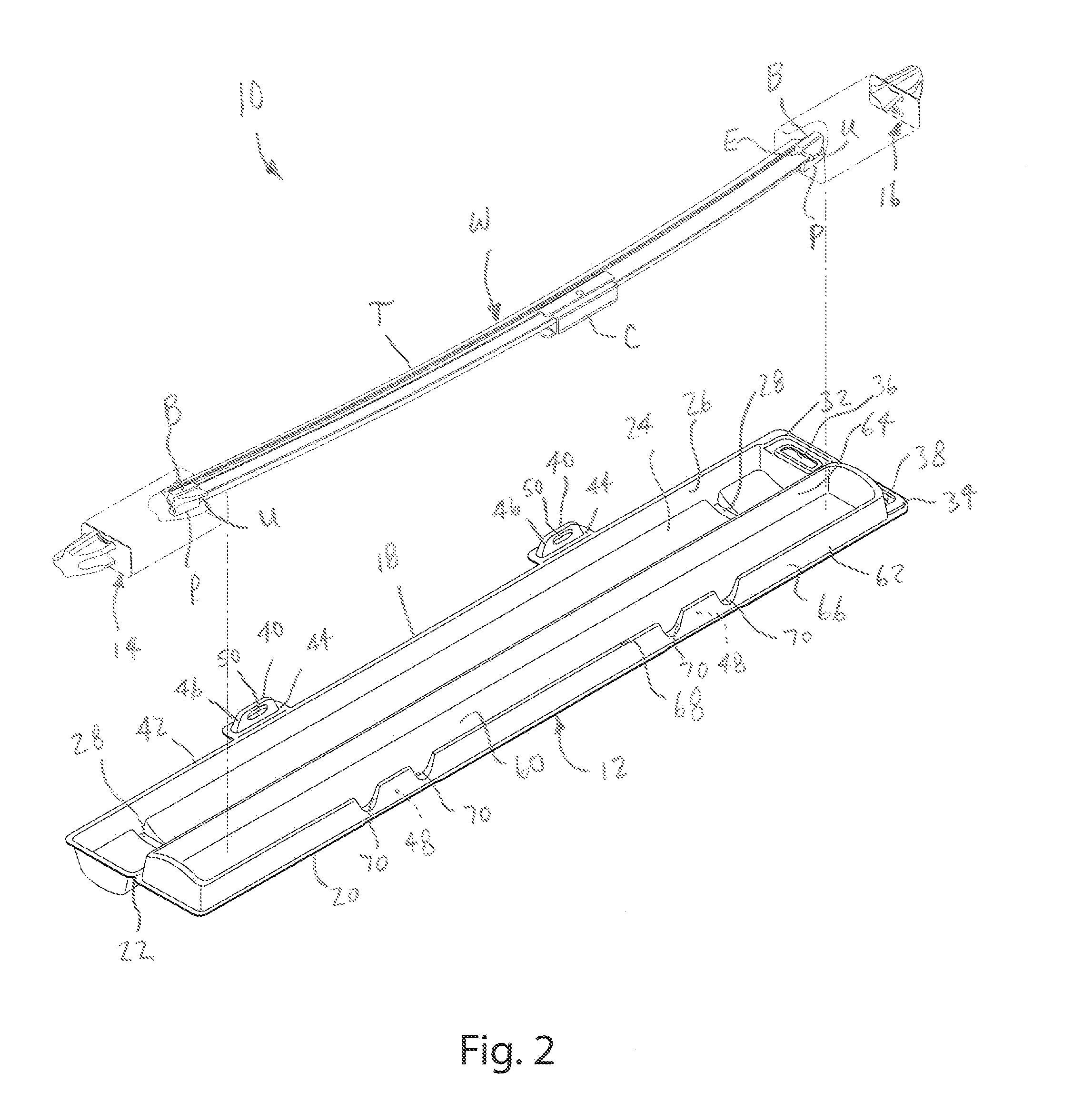

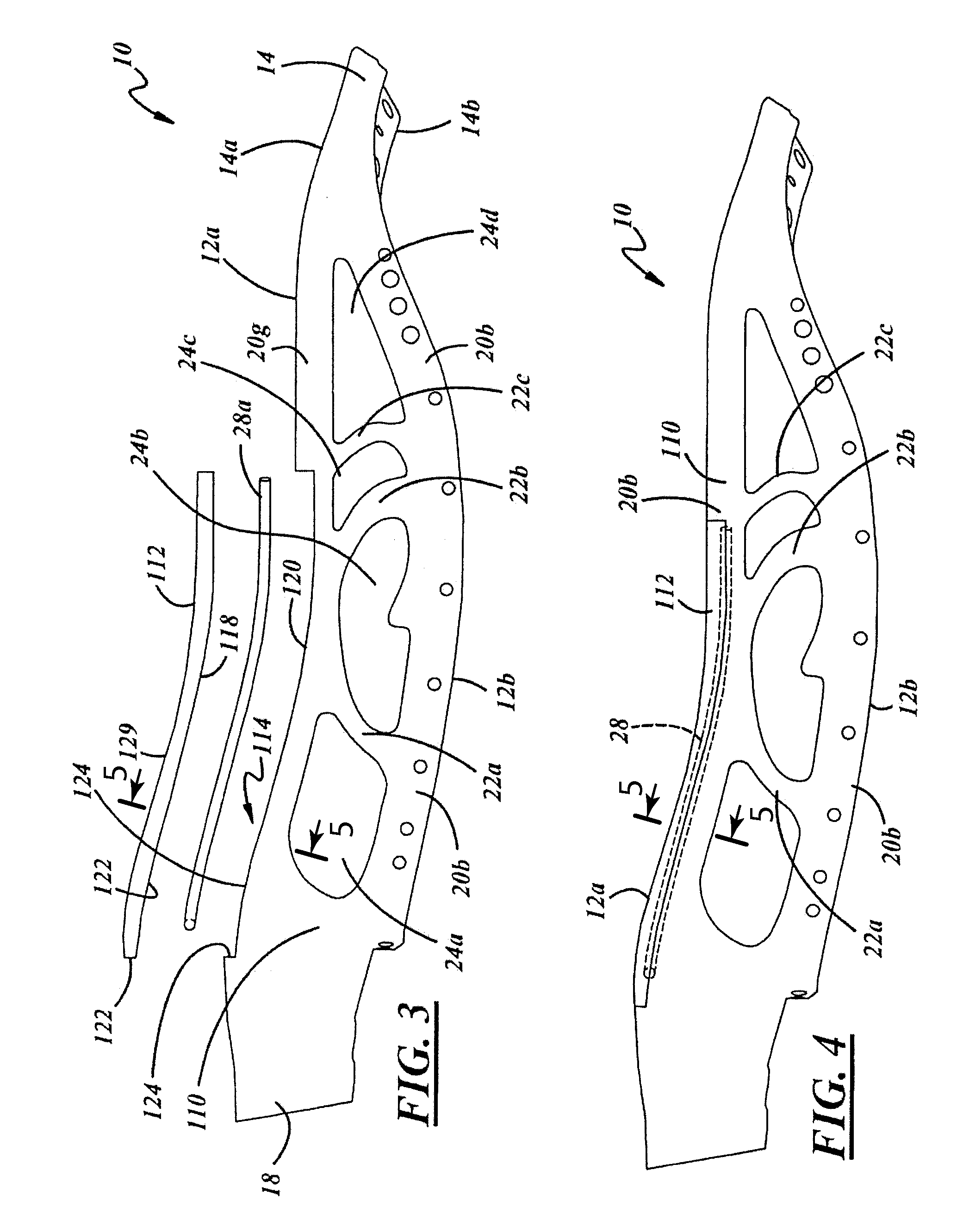

Package assembly for wiper blade

ActiveUS8505724B2Reduce riskReduce widthOther accessoriesTray containersEngineeringMechanical engineering

A wiper package assembly for use in packaging a pre-curved wiper blade. The wiper package assembly generally includes a package and a pair of end caps fittable onto the wiper blade and into the package. The package and end caps may be configured to cooperatively hold the pre-curved wiper blade in an at least partially straightened condition. The end caps may be configured to engage the wiper blade without altering the shape of the wiper blade tip, thereby reducing the risk of the wiper tip becoming deformed during by the package. In one embodiment, the end caps are ambidextrous in the sense that identical end caps can be used on opposite ends of the wiper blade. The end cap may include two support slots configured to correspond with the shape of the opposite ends of an asymmetrical wiper blade.

Owner:DISPLAY PACK

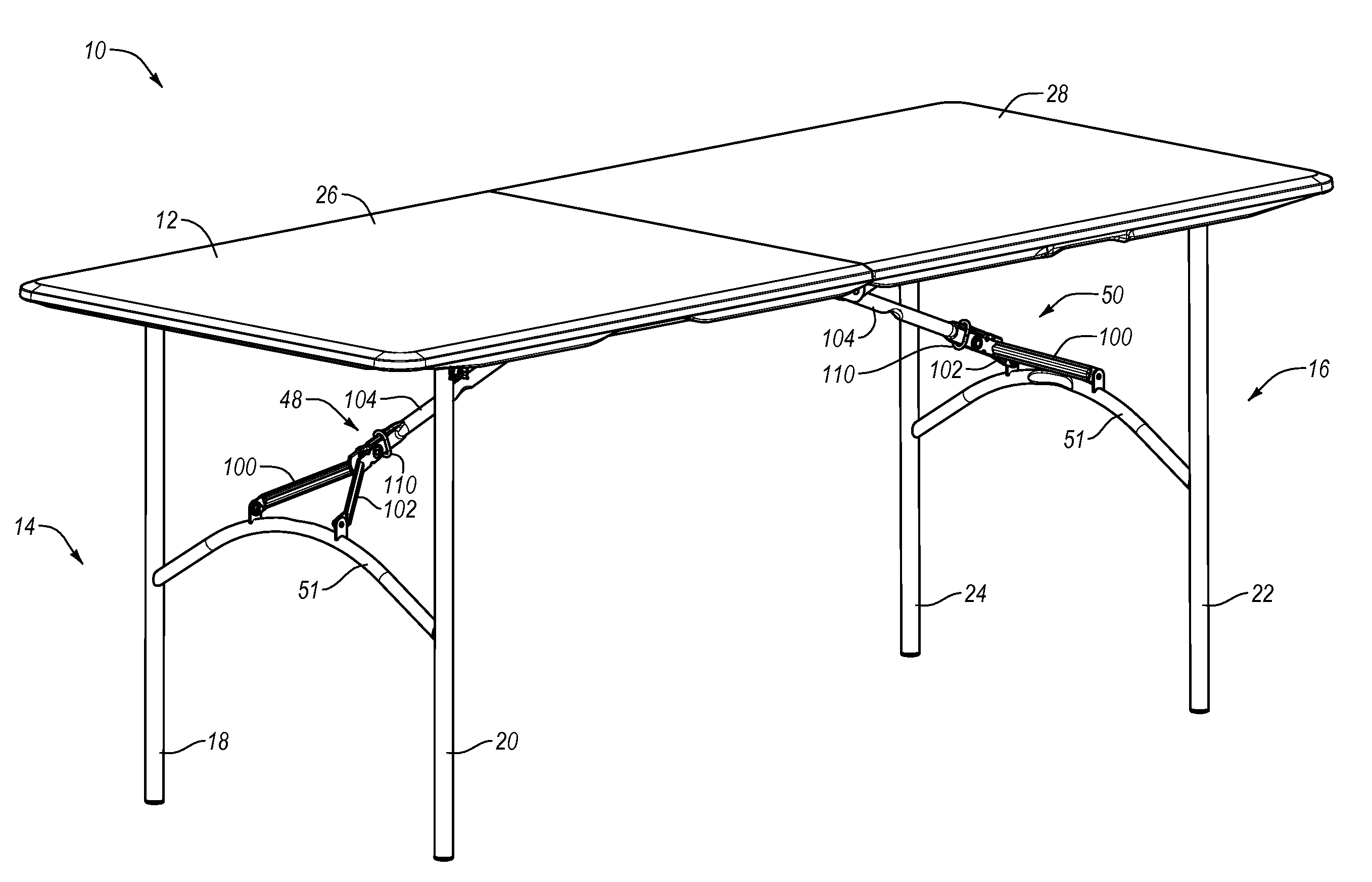

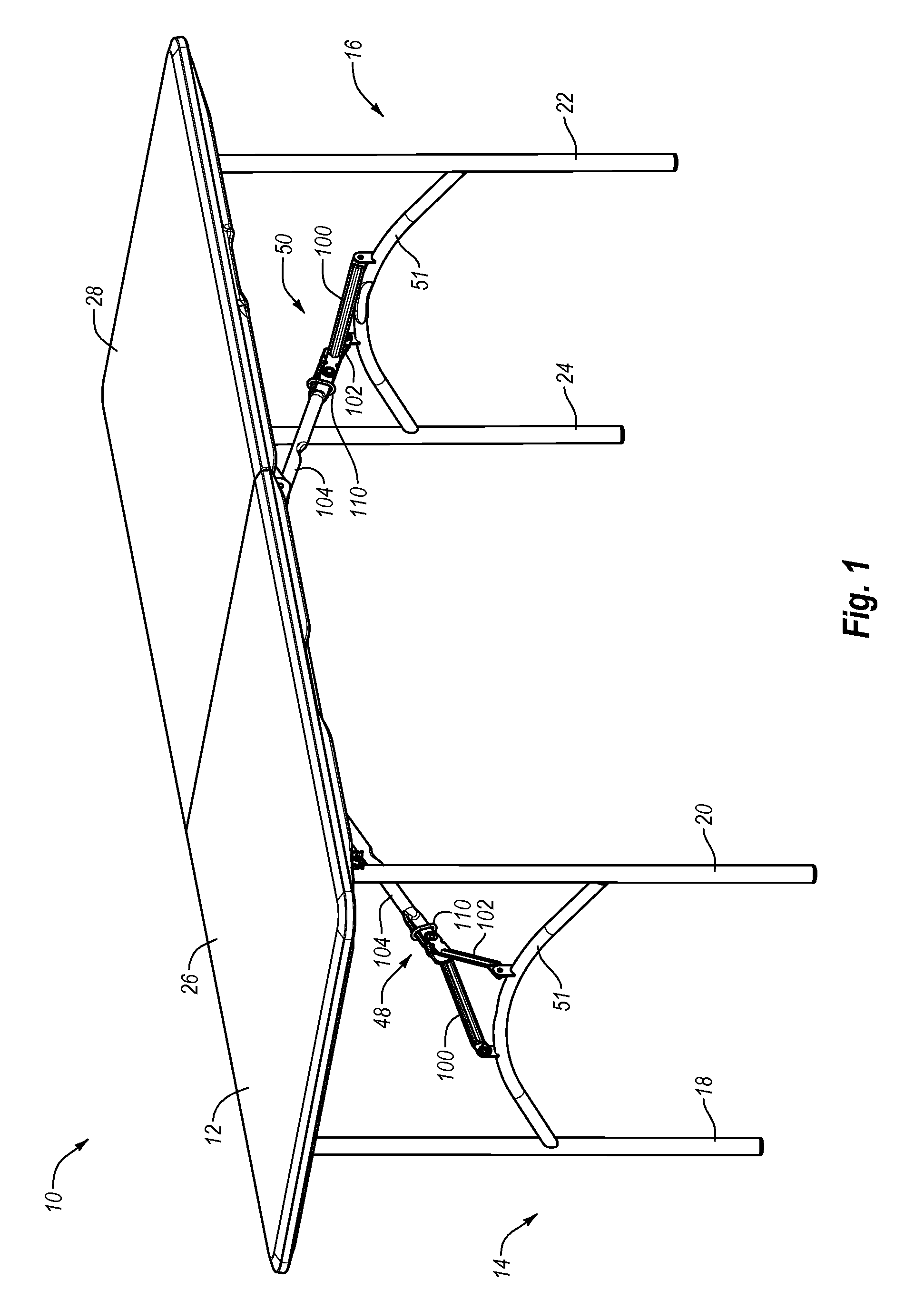

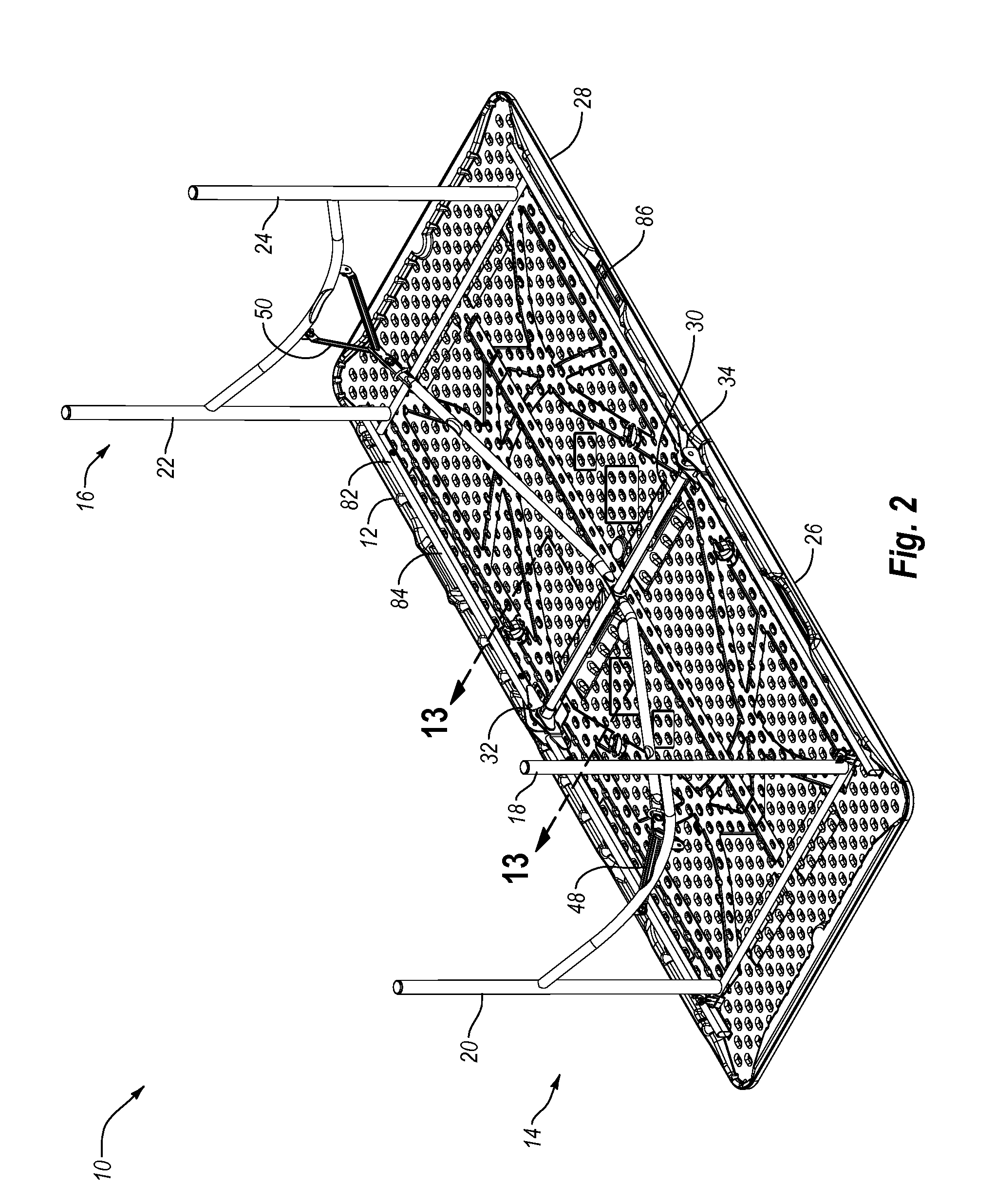

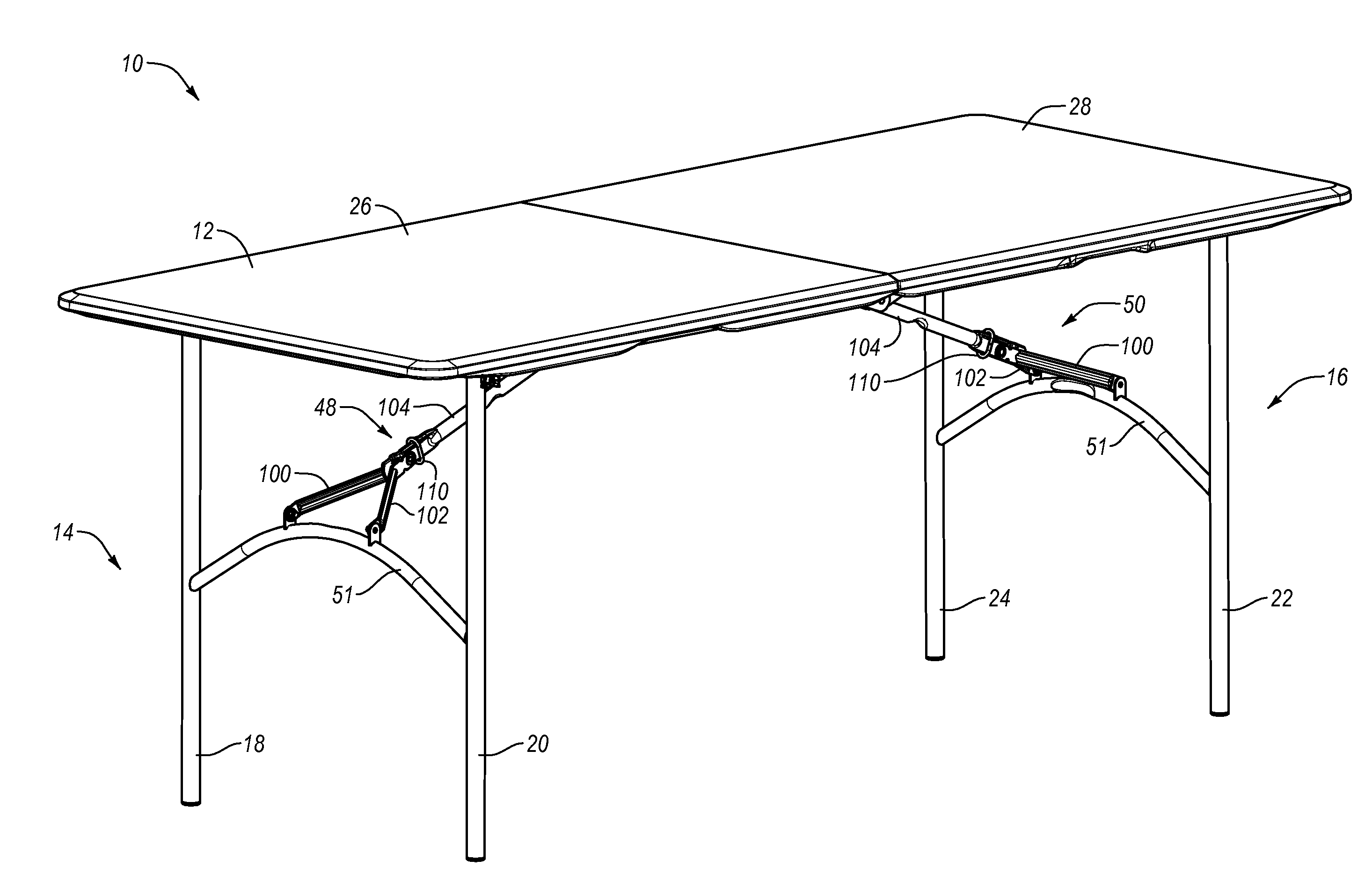

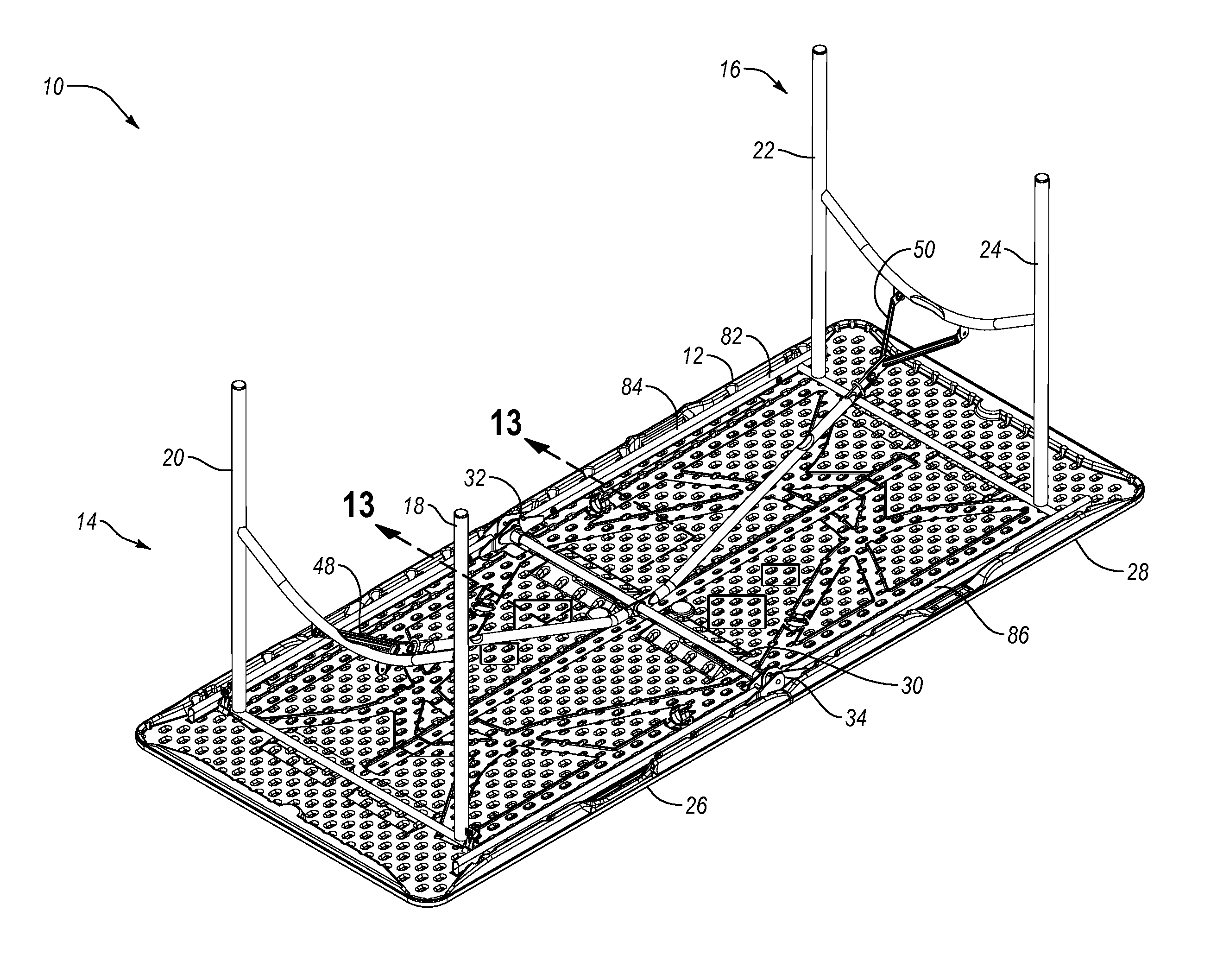

Table

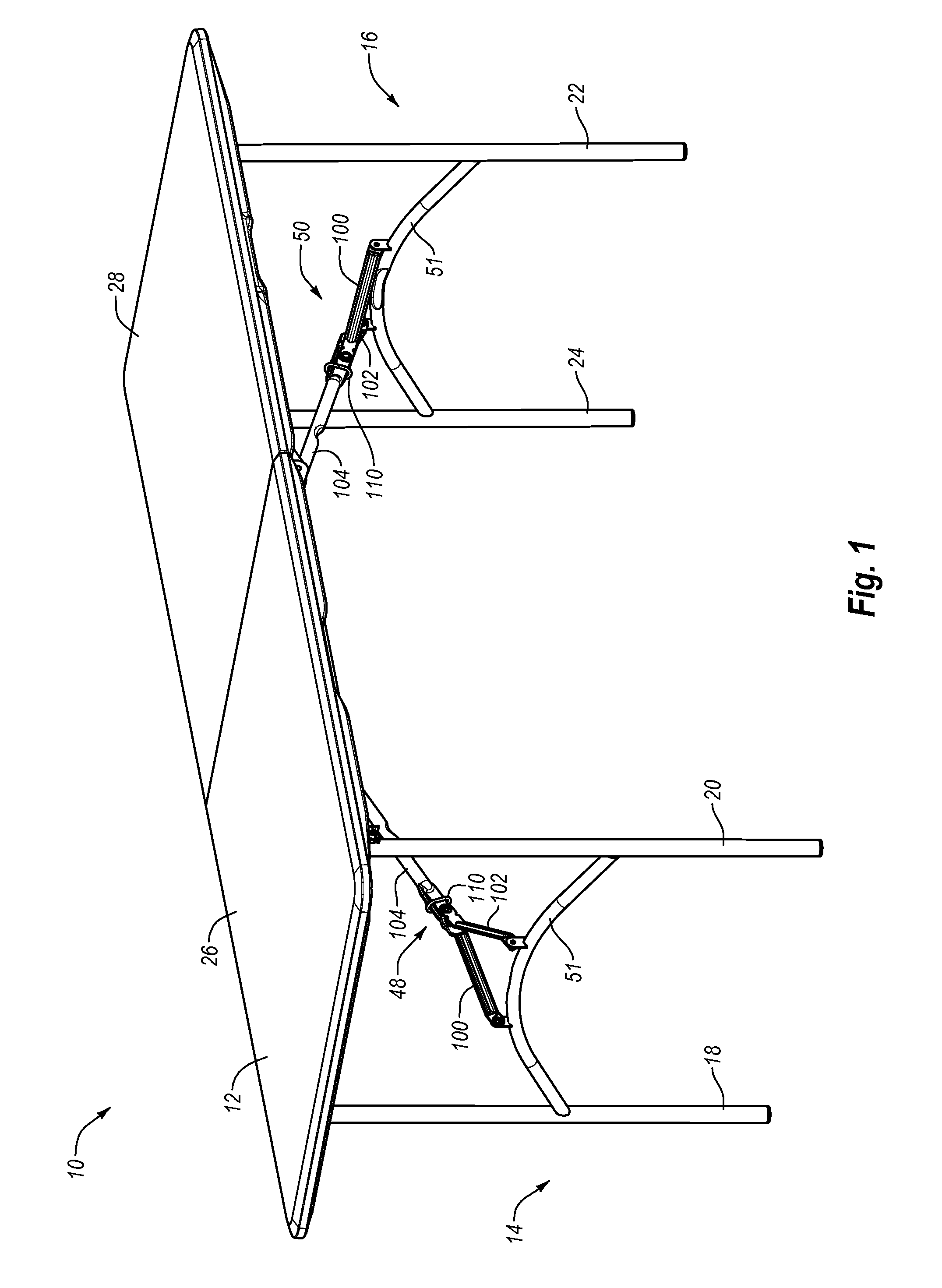

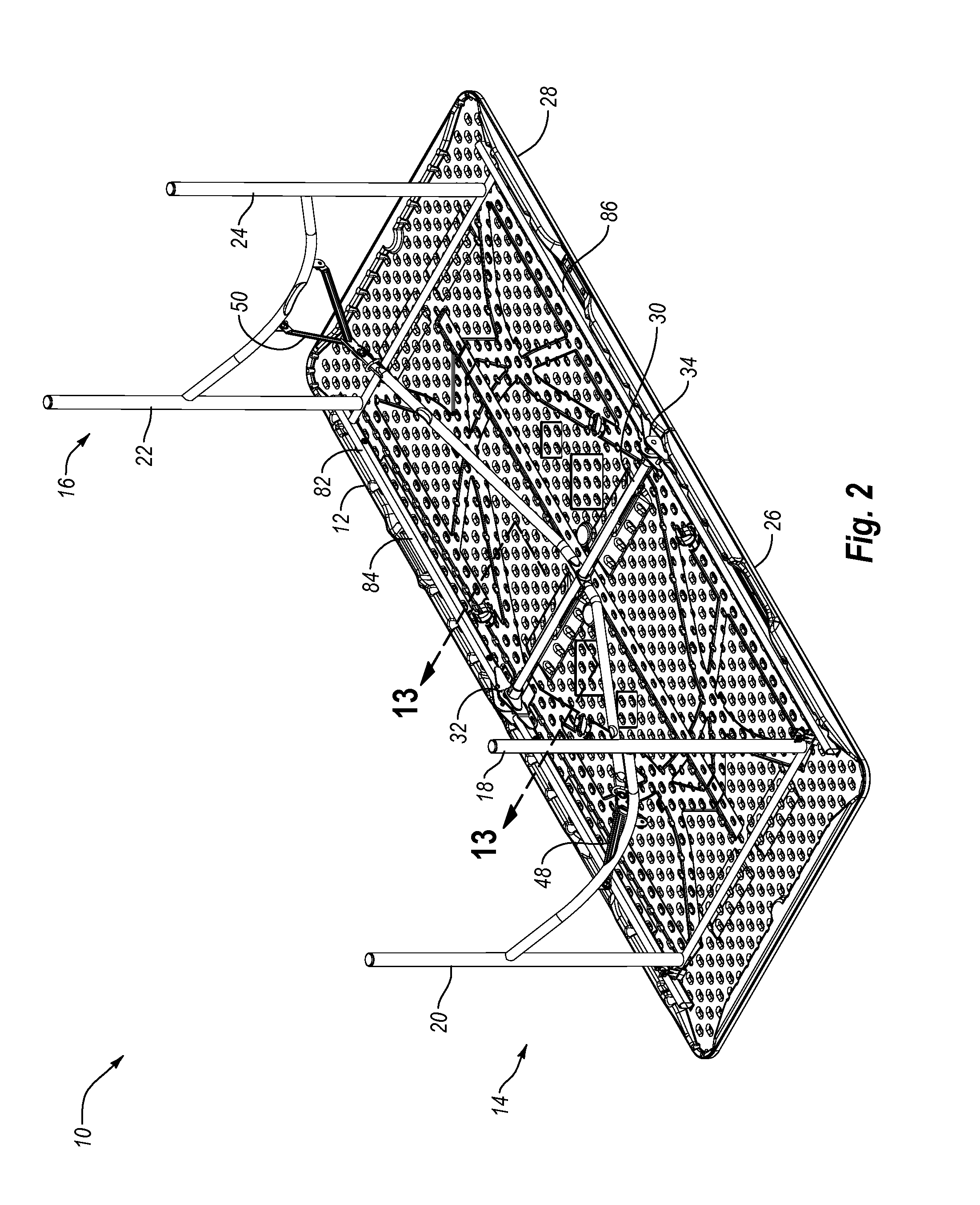

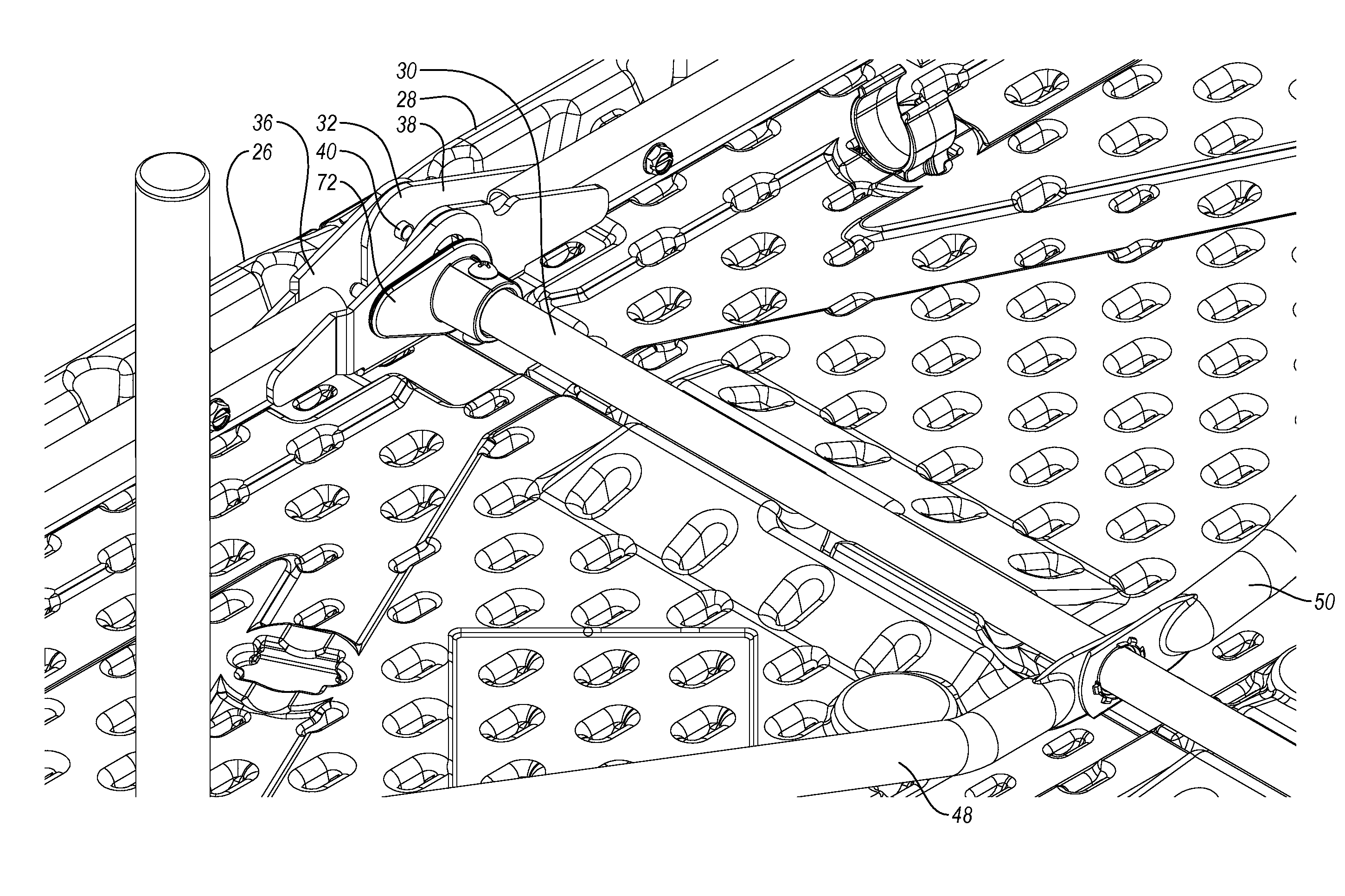

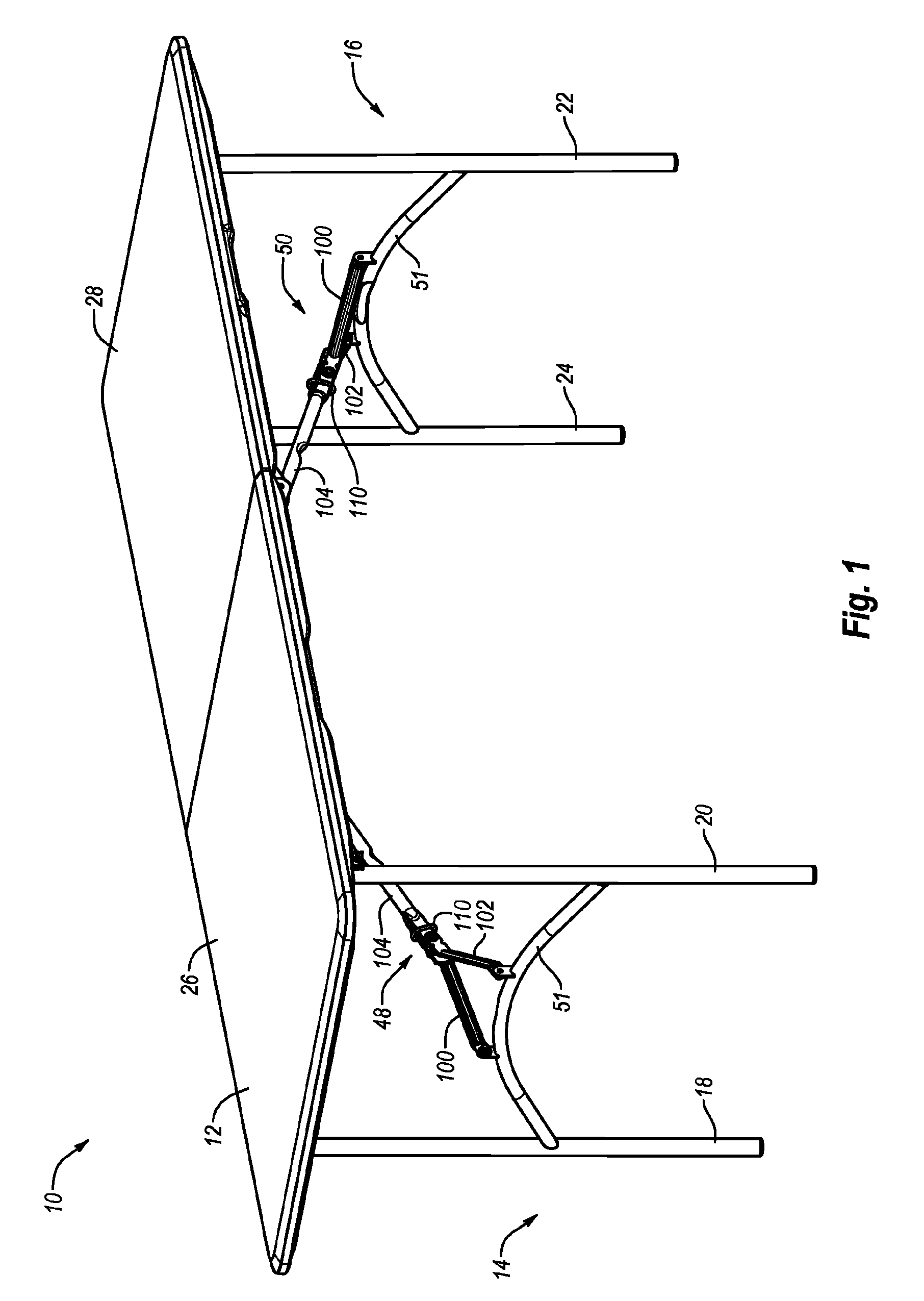

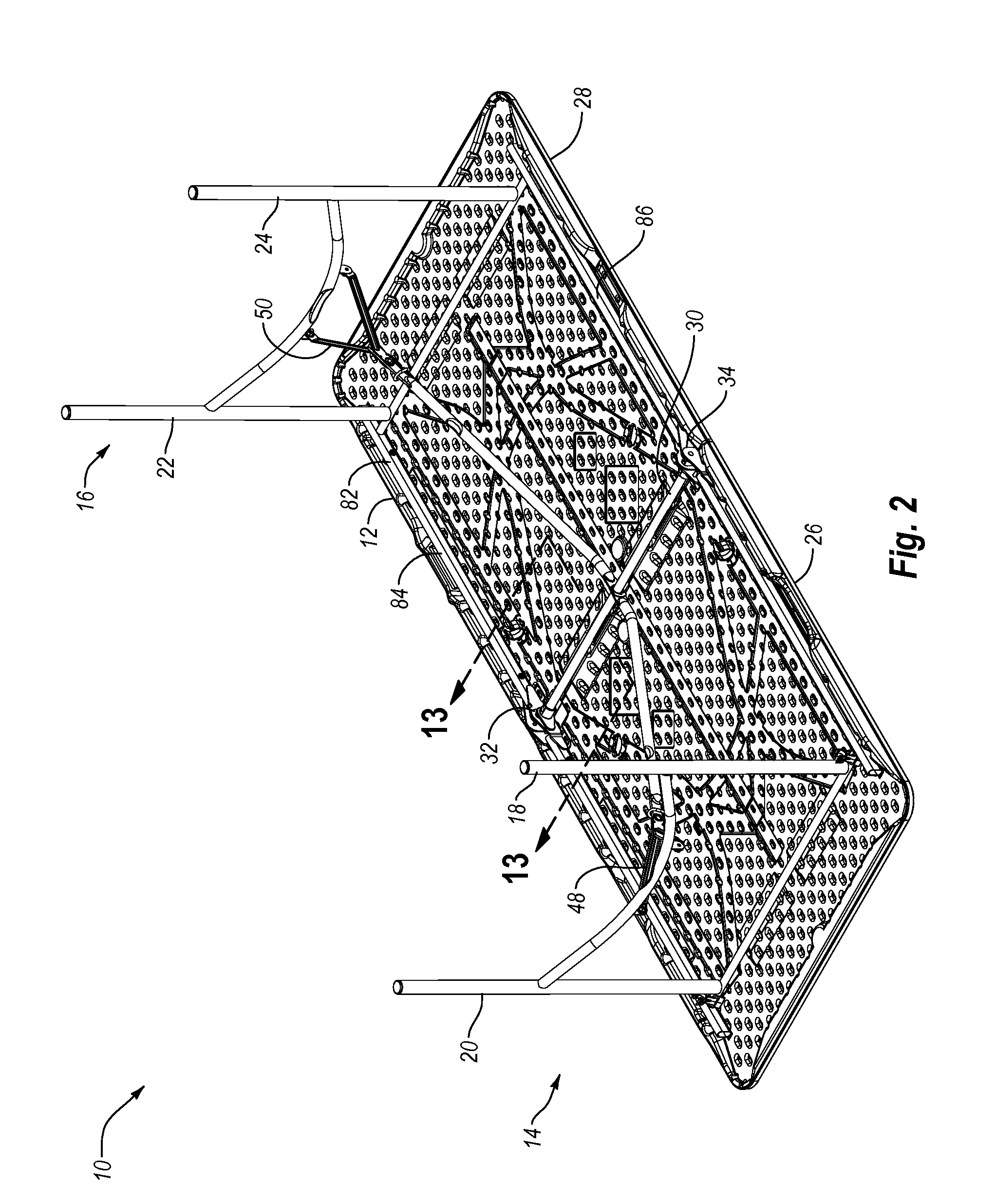

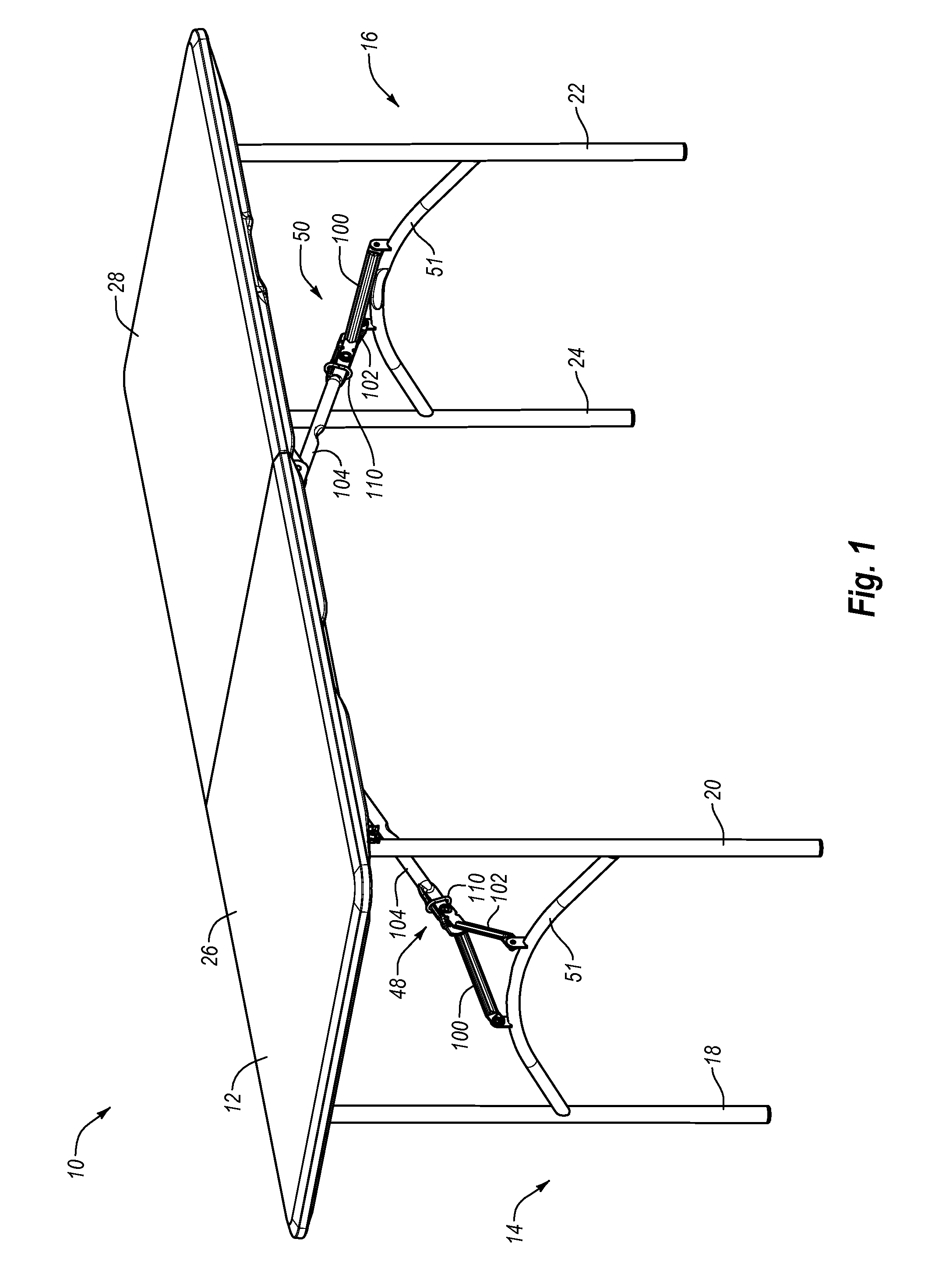

ActiveUS20110203493A1Reduce areaEasy to moveFoldable tablesStowable tablesEngineeringMechanical engineering

A table may include a table top and a leg assembly. The leg assembly may be moved between use and storage positions, and the movement of the leg assembly may move a cross member between a first position in which the cross member resists folding of the table top and a second position in which the cross member facilitates folding and unfolding of the table top. The table top may include first and second sections with portions that overlap and / or interlock when the table top is unfolded. When the table top is in the unfolded position, movement of the leg assembly towards the use position may move the cross member towards the overlapping and / or interlocking portions, which may move the overlapping and / or interlocking portions towards each other. When moved towards each other, the overlapping and / or interlocking portions may be securely connected.

Owner:LIFETIME PRODUCTS

High-intensity wood plastic composite board and fabrication method thereof

InactiveCN101708614AEasy to produceHigh strengthWood veneer joiningFlat articlesMechanical propertyWhite oil

The invention relates to a wood plastic composite, in particular to a high-intensity wood plastic composite board and a fabrication method thereof. The method for fabricating the high-intensity wood plastic composite board comprises the following steps: treating nano titanium dioxide with silane coupling agent to obtain modified nano titanium dioxide; mechanically stirring the modified nano titanium dioxide, plastic particles, maleic anhydride grafted plastic particles, calcium stearate and the like, and extruding and pelleting all the materials to obtain modified plastic particles; mechanically stirring the modified plastic particles, wood flour, terpene resin, chopped glass fiber, white oil, antioxidant and the like, and extruding, melt-blending and pelleting all the materials to obtain high-intensity wood plastic composite particles; and finally extruding the high-intensity wood plastic composite particles with a machine to mold the high-intensity wood plastic composite board. The high-intensity wood plastic composite board has extremely wide application range, and is applied to the fields such as transportation, construction, decoration, ornament, municipal works, garden and park, packaging and the like. The high-intensity wood plastic composite board has the advantages of reproducibility, low cost and higher mechanical properties such as static bending strength and the like, thereby being an ideal material for replacing wood. Compared with traditional wood plastic composites, the high-intensity wood plastic composite board has longer service life, and is a novel upgrade product of the present wood plastic composites.

Owner:江苏森诺塑胶科技有限公司

Anti-ageing wood-plastic composite board and preparation method thereof

InactiveCN101708617AEasy to produceHigh degree of mechanizationDomestic articlesFlat articlesUltravioletStearate

The invention relates to a wood-plastic composite, in particular to an anti-ageing wood-plastic composite board and a preparation method thereof. The anti-ageing wood-plastic composite board of the invention is manufactured by mechanically mixing and melt-mixing wood meal, calcium carbonate powder, plastic particles, maleic anhydride, stearate, pigment, antibacterial agent, antioxidant and ultraviolet absorber in sequence, and extruding and molding the mixture. The anti-ageing wood-plastic composite board has extremely wide application, is suitable for the industries of architectural decoration, transportation, furniture, municipal administration, gardens and the like, is renewable, has low cost, ageing resistance and ultraviolet resistance, is an ideal material for replacing wood, and is a novel upgraded product of the wood-plastic composite.

Owner:江苏森诺塑胶科技有限公司

Table

InactiveUS20110203494A1Reduce areaEasy to moveFoldable tablesStowable tablesEngineeringMechanical engineering

A table may include a table top and a leg assembly. The leg assembly may be moved between use and storage positions, and the movement of the leg assembly may move a cross member between a first position in which the cross member resists folding of the table top and a second position in which the cross member facilitates folding and unfolding of the table top. The table top may include first and second sections with portions that overlap and / or interlock when the table top is unfolded. When the table top is in the unfolded position, movement of the leg assembly towards the use position may move the cross member towards the overlapping and / or interlocking portions, which may move the overlapping and / or interlocking portions towards each other. When moved towards each other, the overlapping and / or interlocking portions may be securely connected.

Owner:LIFETIME PRODUCTS

Folding table with locking member

ActiveUS8397653B2Reduce areaEasy to moveFoldable tablesStowable tablesMechanical engineeringEngineering

Owner:LIFETIME PRODUCTS

Surface flame-retardant wood-plastic composite material plate and preparation thereof

InactiveCN101486267AReasonable designSimple structureSynthetic resin layered productsFiberMagnesium Sulfate whiskers

The invention relates to a surface flame retarded wood plastic composite plate and a method for preparing the same, which relates to a composite material, an environment-friendly material and a method for preparing the same. The composite material is applicable to making the following products: floor boards, shelf boards, and the like for means of transportation such as automobiles, planes, and the like in the field of transportation; road slabs, fences, wallboards, aisle guard bars, and the like in the field of construction; and outdoor desks and chairs, office partition boards, storage boxes, flower boxes, adjustable shelves, beach chairs, and the like in the furniture industry. The surface flame retarded wood plastic composite plate consists of two layers of crystal whisker modified plastic layers and plant fiber reinforced plastic layers, wherein the plant fiber reinforced plastic layers are arranged between the two layers of the crystal whisker modified plastic layers through die stamping. The crystal whisker modified plastic layers are made from modified basic magnesium sulfate whiskers, plastic particles, and the like through mixed calendering. The plant fiber reinforced plastic layers are made from plastic particles and plant fibers through mixed calendering.

Owner:NANJING FORESTRY UNIV

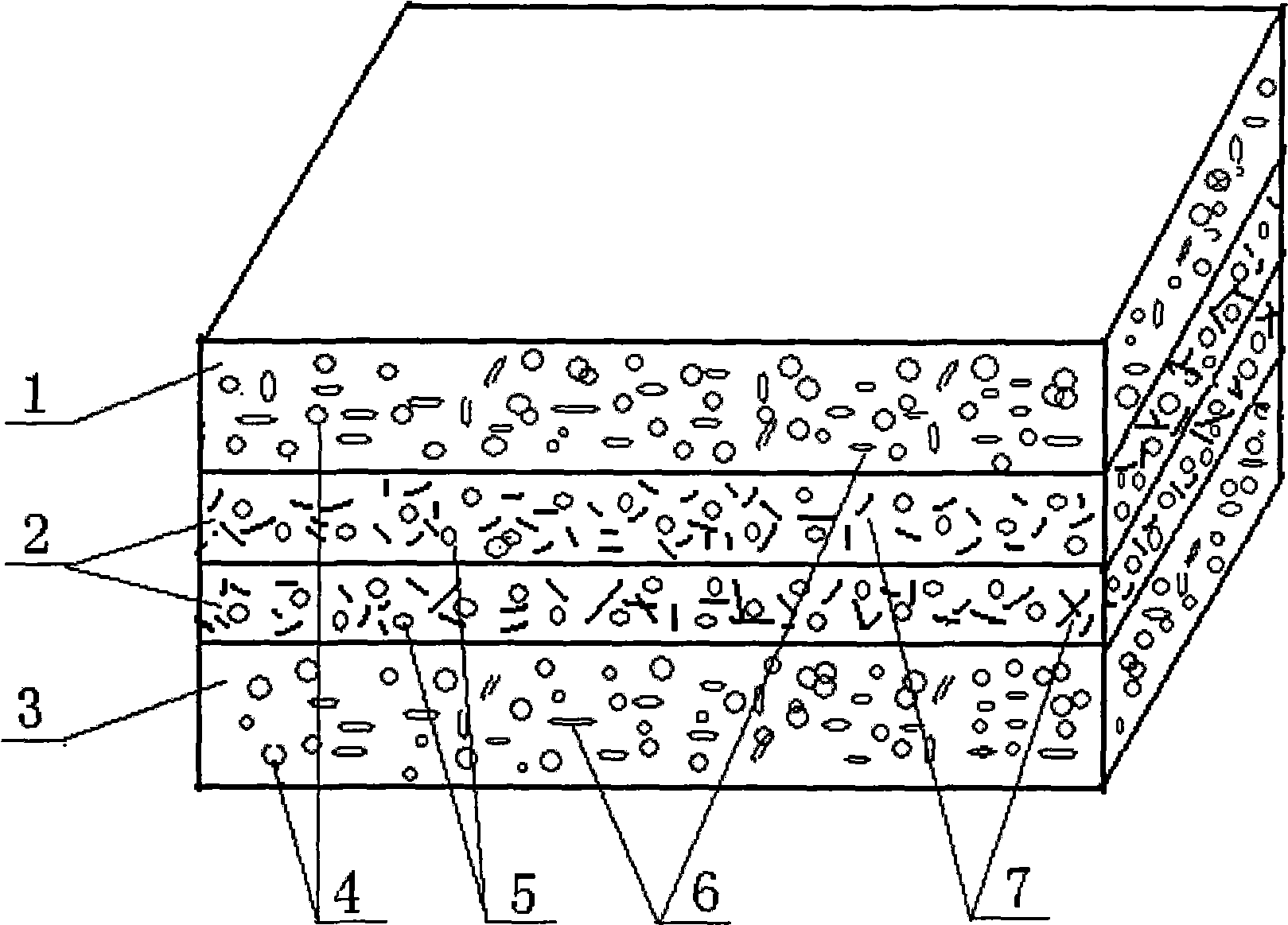

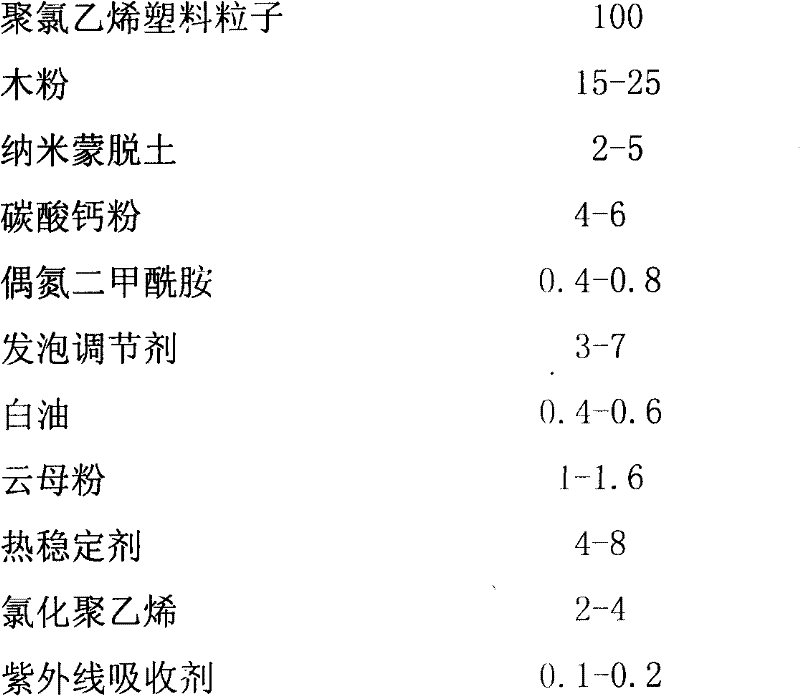

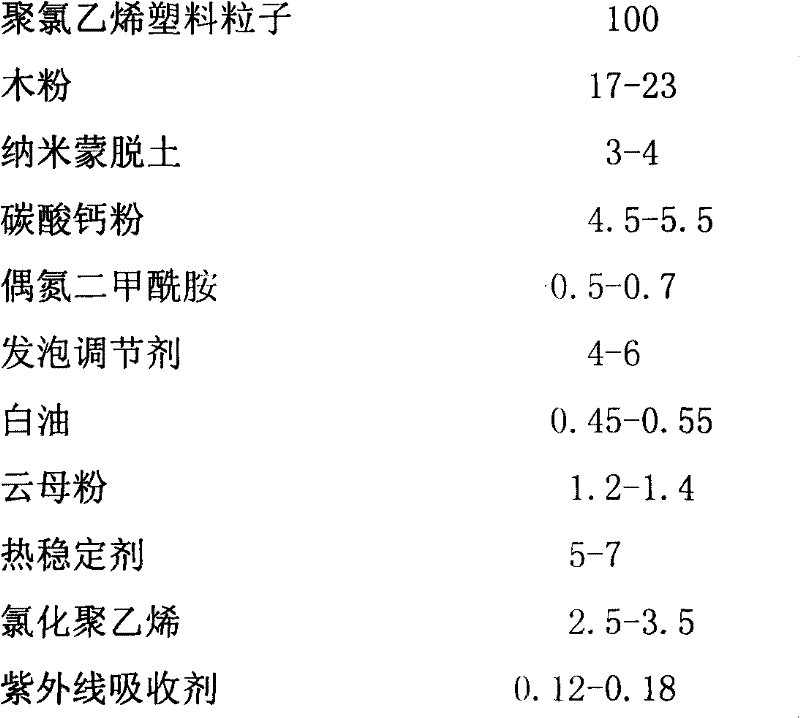

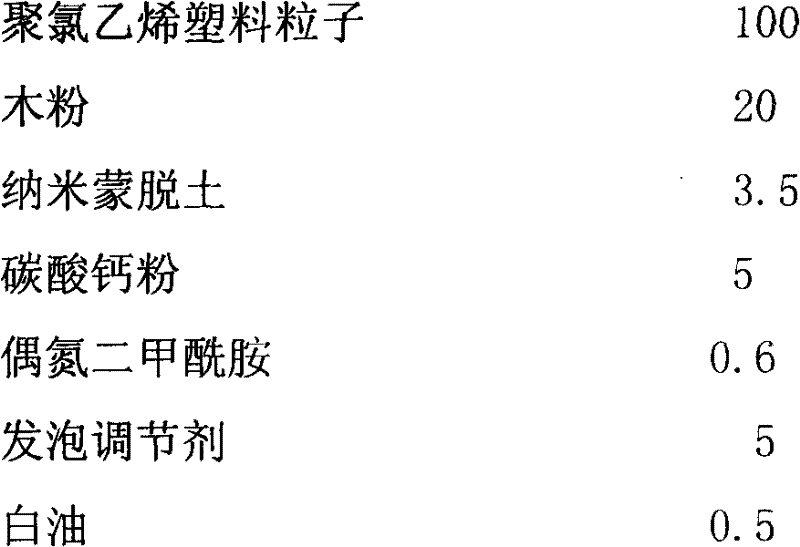

Micro-foaming wood plastic composite sheet and preparation method thereof

The invention relates to a wood plastic material and particularly relates to a micro-foaming wood plastic composite sheet and a preparation method thereof. The method provided by the invention comprises the following steps: evenly mixing polyvinyl chloride, nano-montmorillonite, calcium carbonate powder, white oil, a heat stabilizer and mica powder are uniformly stirred; and then carrying out extruding pelletization to obtain modified plastic particles; and then uniformly stirring the modified plastic particles with wood meal, azobisformamide, a foaming regulator, chlorinated polyethylene andan ultraviolent absorbent, and performing extrusion and foaming formation to obtain the micro-foaming wood plastic sheet. The micro-foaming wood plastic sheet has high degree of mechanization and lowcost, is lower in density, less in plastic amount and more environmentally-friendly compared with plastic sheets, is lower in density and higher in impact strength compared with other wood plastic materials, is lower in weight and cost and more convenient in installation and maintenance compared with gypsum boards, aluminum pinch plates and the like, and also has an air purification function. Themicro-foaming wood plastic sheet can be manufactured into products, such as photo frames, picture frames, skirtings, hangers and pinch plates and the like, and is widely applied to plenty of occasions, such as halls, guest houses, small offices and the like.

Owner:扬州润友复合材料有限公司

Wood plastic composite plate capable of adsorbing toxic gas, and preparation method thereof

The invention relates to a wood plastic composite material, in particular to a wood plastic composite plate capable of adsorbing toxic gas, and a preparation method thereof. The wood plastic composite plate is characterized by: adopting silane coupling agent modified wood flour as a raw material, mixing polyvinyl chloride, nano-magnesium oxide, active carbon and a heat stabilizer through stirringto obtain modified plastic particles; uniformly stirring the modified plastic particles, the modified wood flour, azobisformamide, a composite foaming agent, acrylic acid, chlorinated polyethylene and a ultraviolet absorber, followed by extruding, foaming and forming to obtain the wood plastic composite plate. The preparation method for the wood plastic composite plate is convenient. Compared to a common plastic plate, a gypsum board, a aluminum buckle plate and other wood plastic materials, the wood plastic composite plate provided by the present invention has characteristics of low density,light weight, high impact strength, low cost and toxic gas adsorbing, and can be made into a plurality of products such as photo frame, picture frame, ground pin line and the like, and can be widely applicable for a plurality of situations such as auditoriums and hotels, homes, office buildings, and the like.

Owner:扬州润友复合材料有限公司

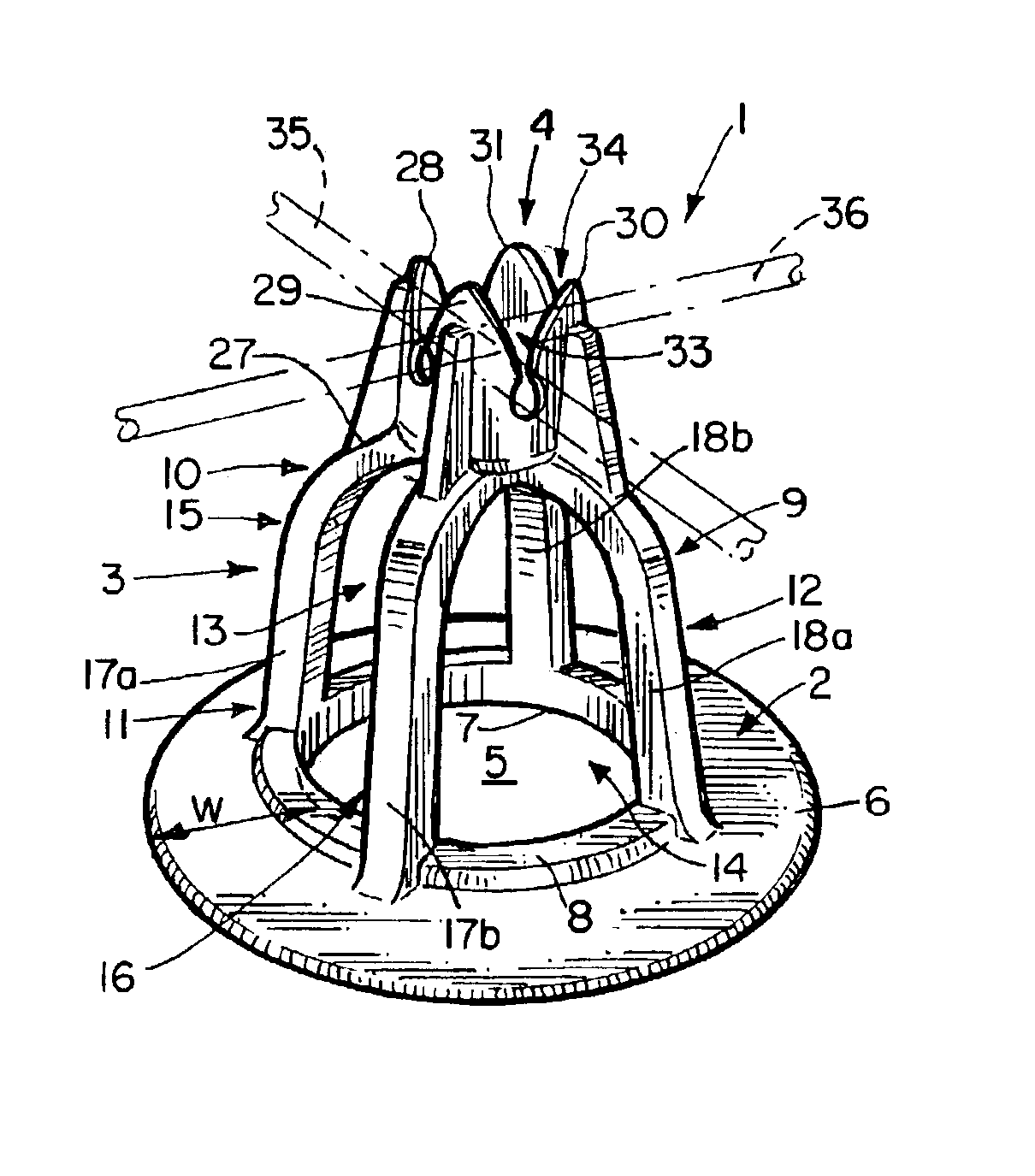

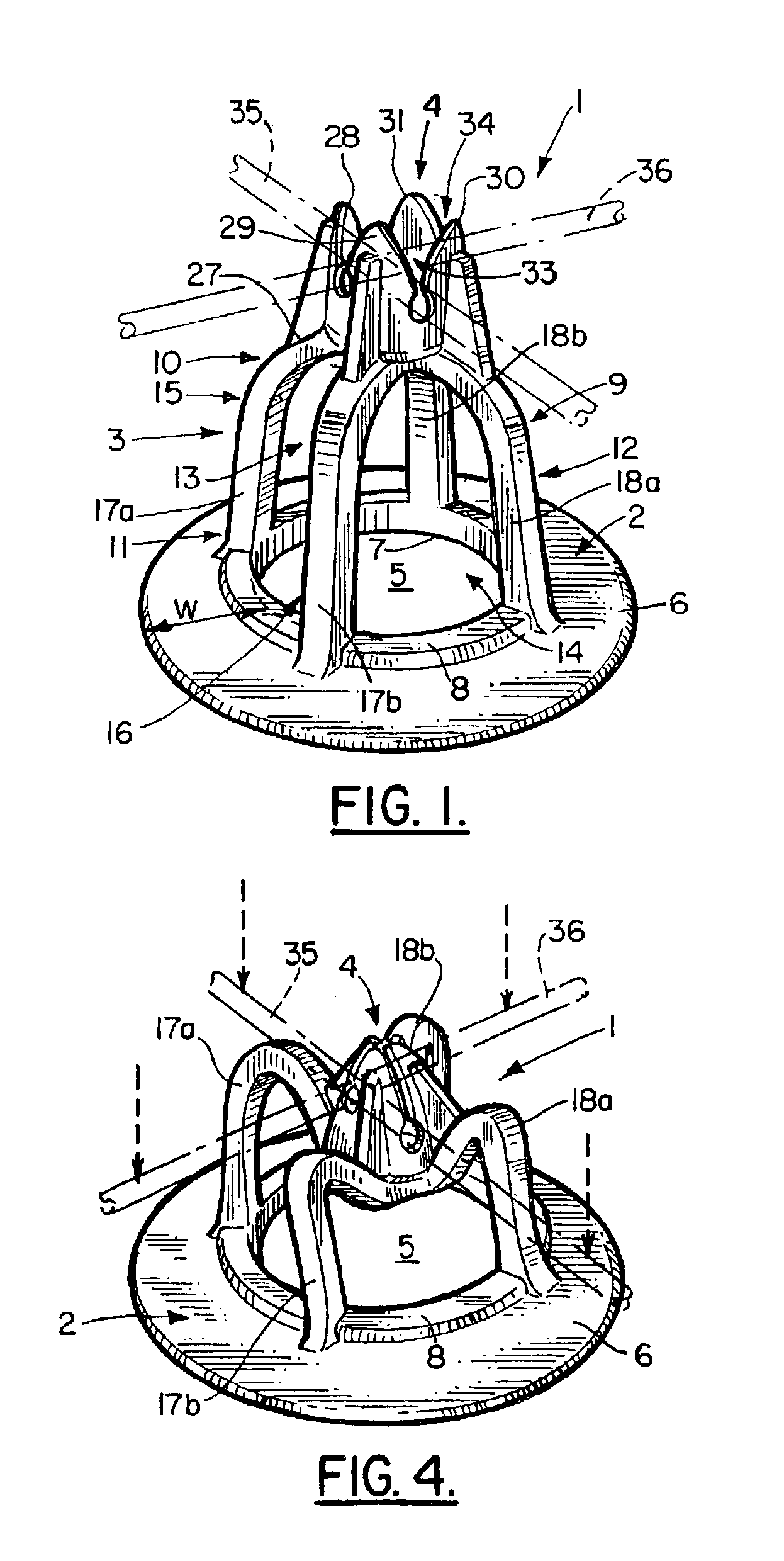

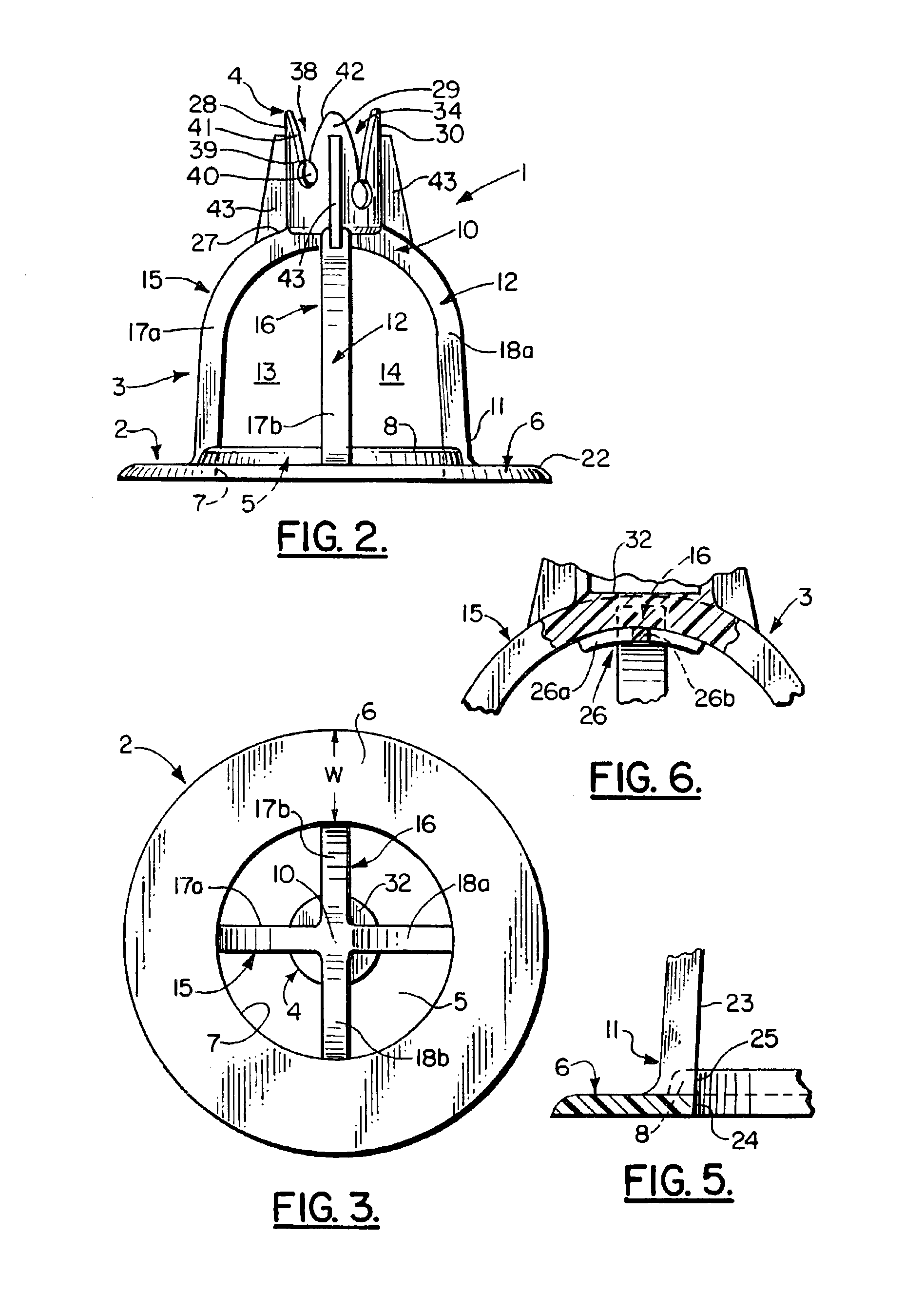

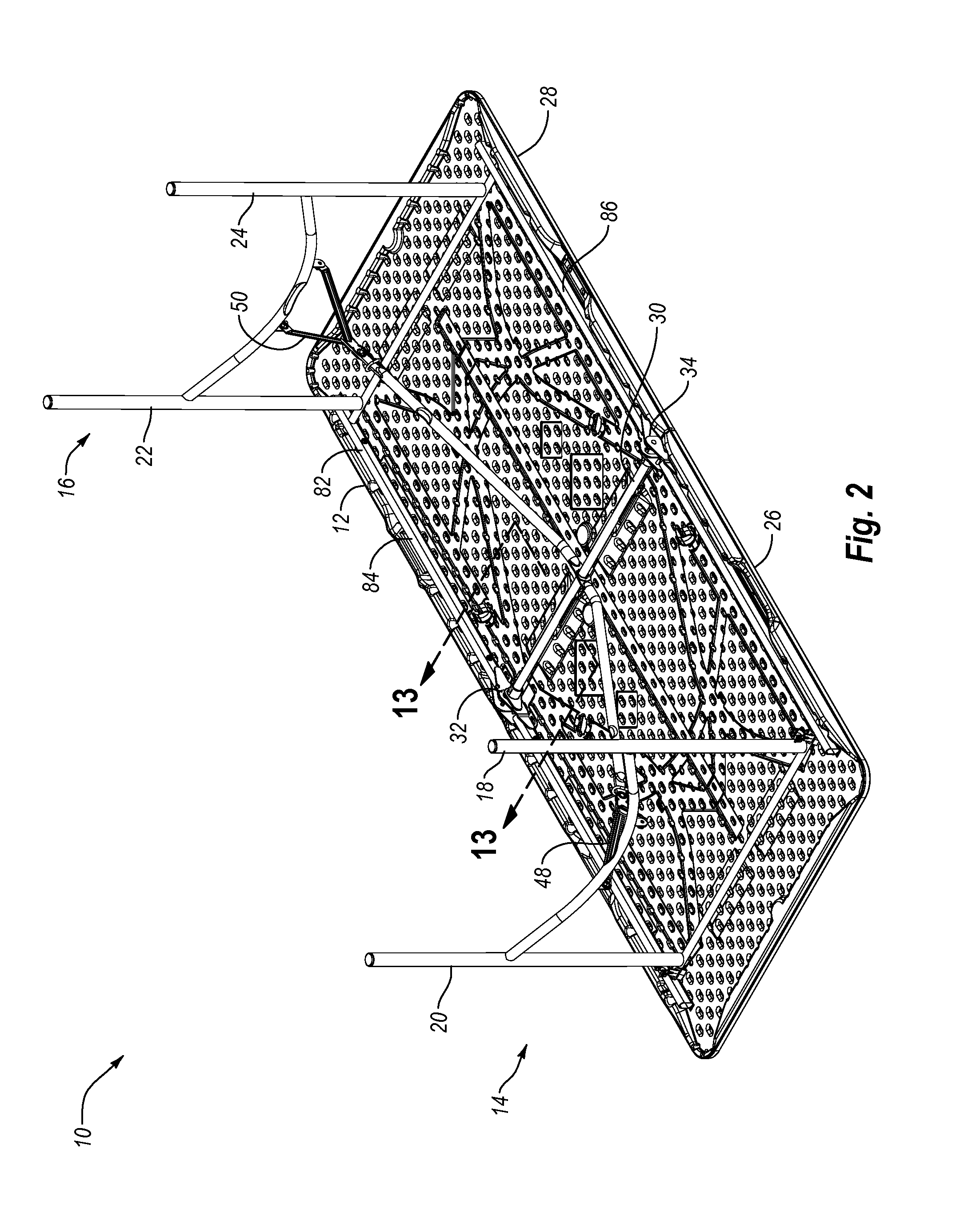

Chair for supporting wire mesh

InactiveUS6962029B2Reduce crackingLess plasticPaving detailsBuilding reinforcementsHigh densityEngineering

An improved chair for supporting intersecting wires forming a wire mesh at a pre-selected elevated position above a bearing surface during formation of a concrete slab is constructed having a base member shaped to rest on the bearing surface, a compressible support structure having a lower section affixed to the base member, a middle section and an upper section affixed to a setting shaped to support the wire mess at the elevated position. The chair is constructed having an improved compressible, generally bell-shape support structure having two pairs of opposing arched-shaped openings in the middle section forming two intersecting arches, each arch having a pair of opposing flexible legs that bow outward when a pre-determined load is applied to the upper section. The support structure further having a strengthening plate affixed on an interior surface of the upper section of the support structure formed by the intersecting arches. The chair constructed from a blend of high density and low density crystalline polymer.

Owner:JOHN L LOWERY & ASSOC

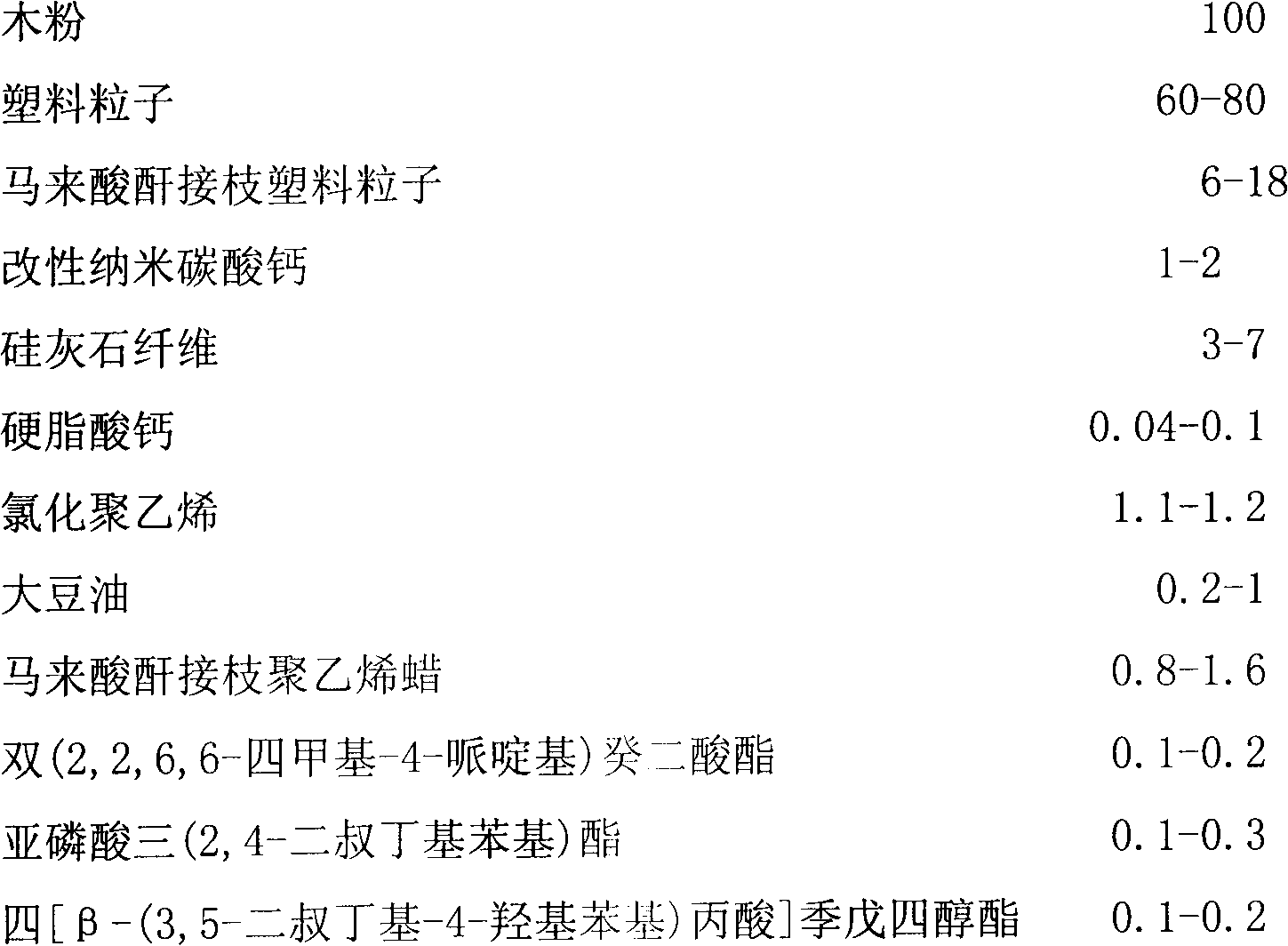

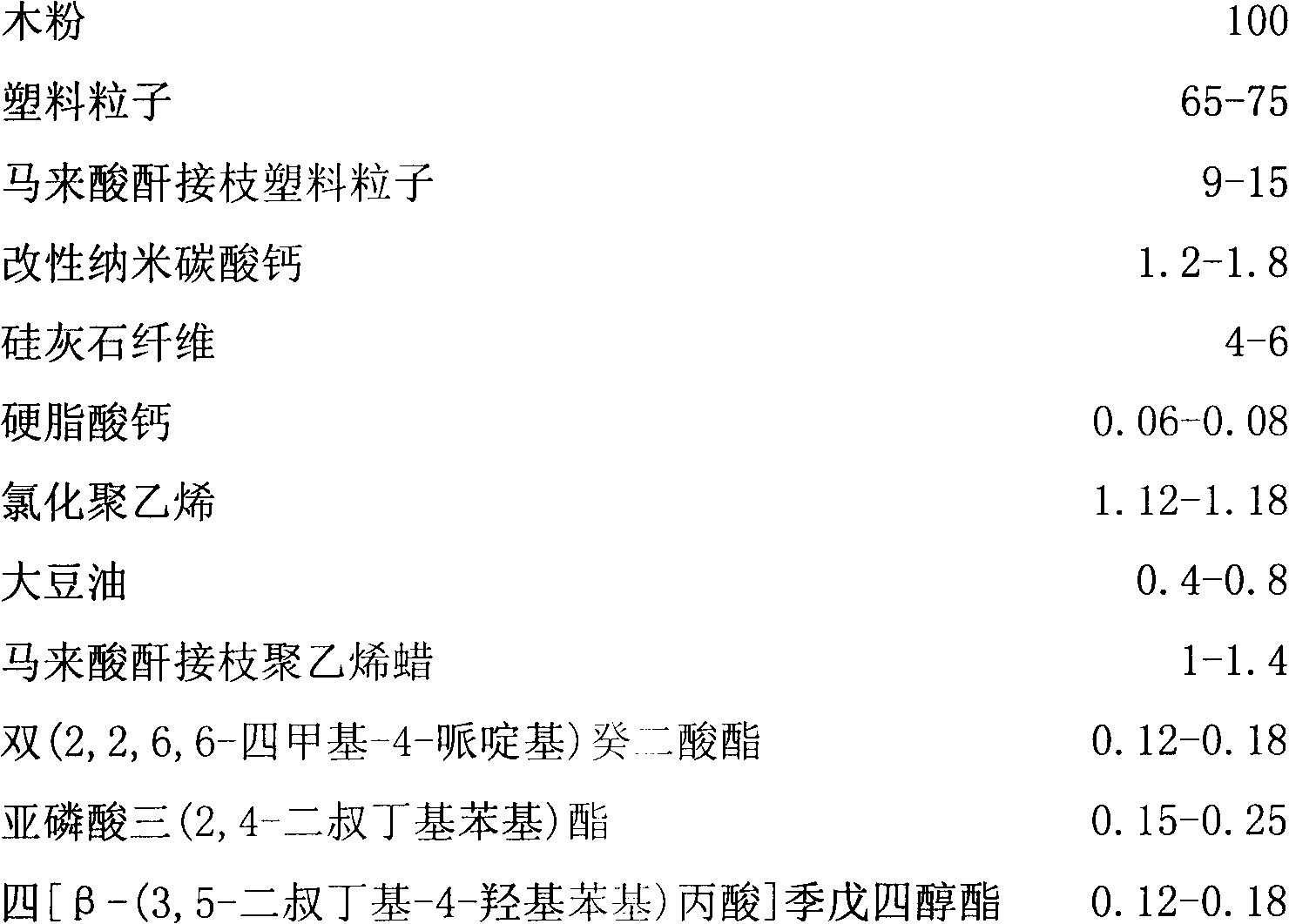

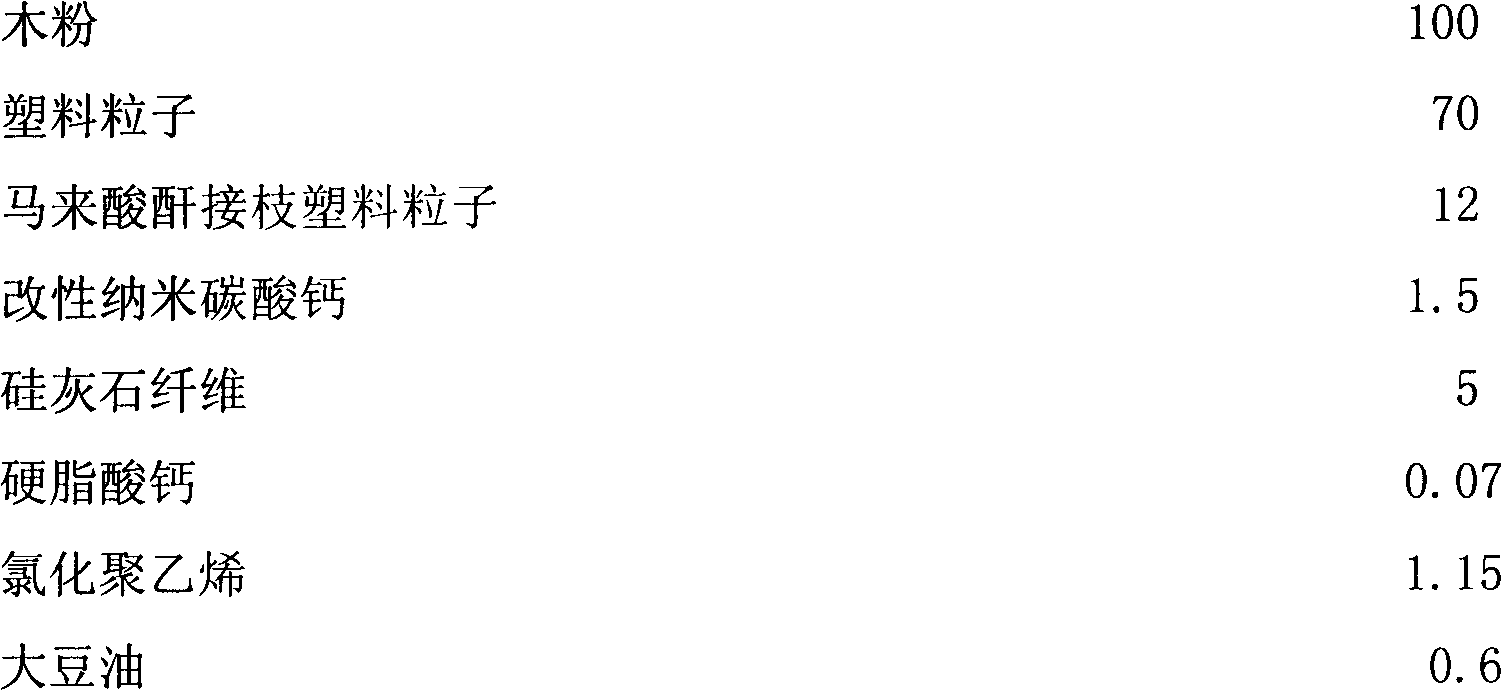

High-strength plastic wood dalle and preparation method thereof

The invention relates to a high-strength plastic wood dalle and a preparation method thereof. The preparation method comprises the following steps of: modifying nano calcium carbonate by a coupling agent; then carrying out treatment by ultrasonic waves to obtain nano modified wood powder; obtaining modified plastic particles by plastic particles, maleic anhydride grafted plastic particles, wollastonite fibers, calcium stearate and chlorinated polyethylene; obtaining high-strength plastic wood particles by the modified plastic particles, the nano modified wood powder, soybean oil, maleic anhydride grafted polyethylene wax, bi(2,2,6,6-tetramethyl-4-piperidyl) sebacate, tris(2,4-di-t-butylphenyl)phosphite and pentaerythritol tetrakis(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate); and finally forming the high-strength plastic wood dalle. The high-strength plastic wood dalle is convenient to produce, has low cost, has low plastic content, is environmental-friendly, has high bending strength and modulus and high ridigity and has creep resistance and aging resistance. The color of the high-strength plastic wood dalle cannot be changed after the high-strength plastic wood dalle is usedfor a long time. Few mechanical properties are reduced. The service life of the high-strength plastic wood dalle is long. The high-strength plastic wood dalle can be widely applied to various fields of traffic, decoration, municipal garden, packaging and the like.

Owner:江苏福瑞森塑木科技股份有限公司

Flame-retardant and environment-friendly material for electric automotive trims and preparation method of material

The invention discloses a flame-retardant and environment-friendly material for electric automotive trims and a preparation method of the material. The material is prepared from 200-350 parts of polypropylene resin, 80-150 parts of filler, 6-12 parts of PE wax, 2-5 parts of maleic anhydride graft, 2-5 parts of a titanate coupling agent, 6-12 parts of an activator, 2-5 parts of ethylene bisoleamide, 12-25 parts of an expanding flame retardant, 6-15 parts of an external lubricant, 5-10 parts of an internal lubricant, 10-25 parts of a stabilizer and a proper amount of dye. The preparation method comprises the process of mixing at a high temperature, treating by stirring and extrusion molding. The flame-retardant and environment-friendly material is high in surface glossiness, non-tacky, attractive in appearance, firm and durable without deformation, good in quality product and wide in application range, and has bright development prospect.

Owner:SHANDONG XINHAI NEW MATERIAL

Table

A table may include a table top and a leg assembly. The leg assembly may be moved between use and storage positions, and the movement of the leg assembly may move a cross member between a first position in which the cross member resists folding of the table top and a second position in which the cross member facilitates folding and unfolding of the table top. The table top may include first and second sections with portions that overlap and / or interlock when the table top is unfolded. When the table top is in the unfolded position, movement of the leg assembly towards the use position may move the cross member towards the overlapping and / or interlocking portions, which may move the overlapping and / or interlocking portions towards each other. When moved towards each other, the overlapping and / or interlocking portions may be securely connected.

Owner:LIFETIME PRODUCTS

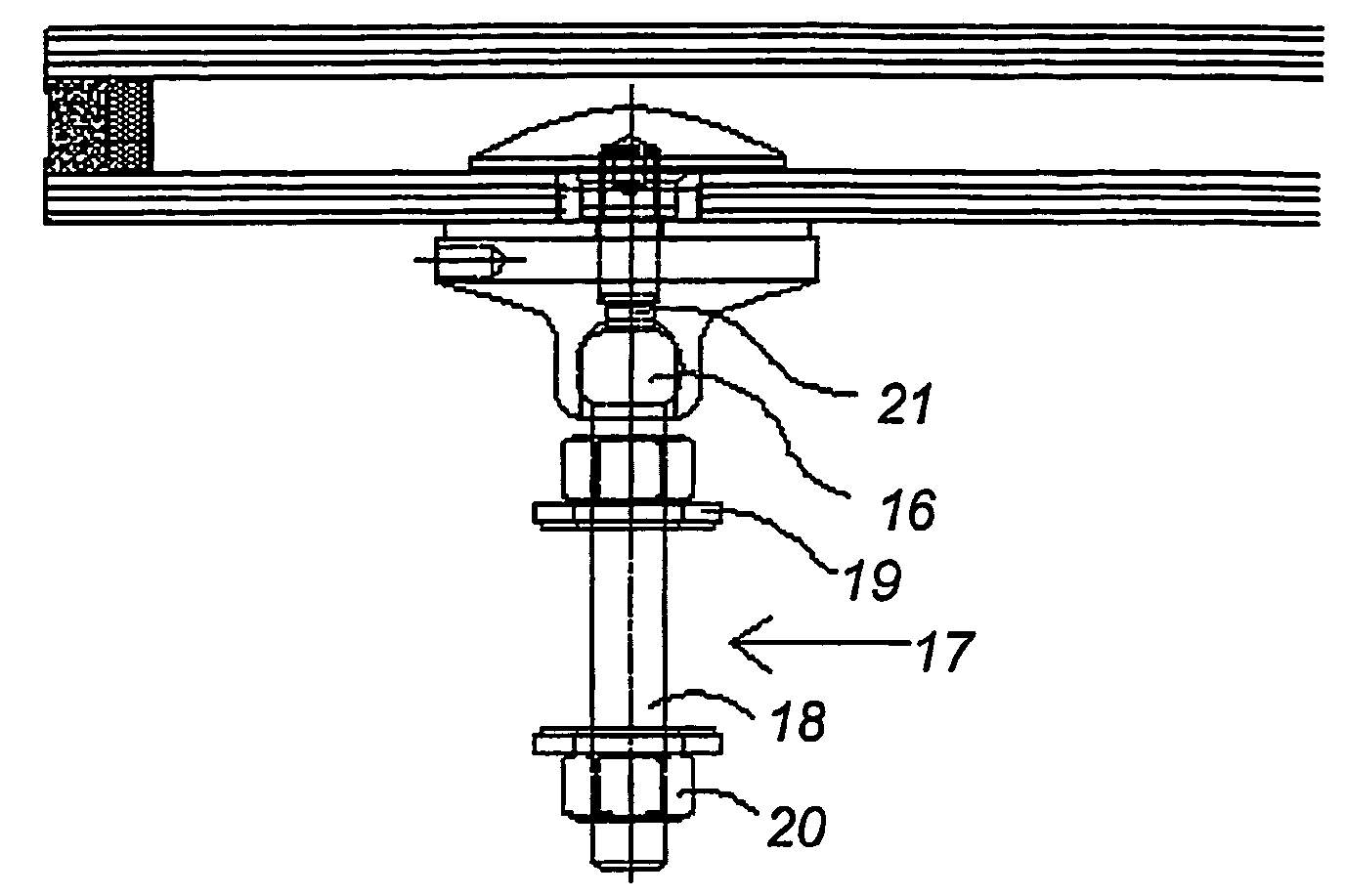

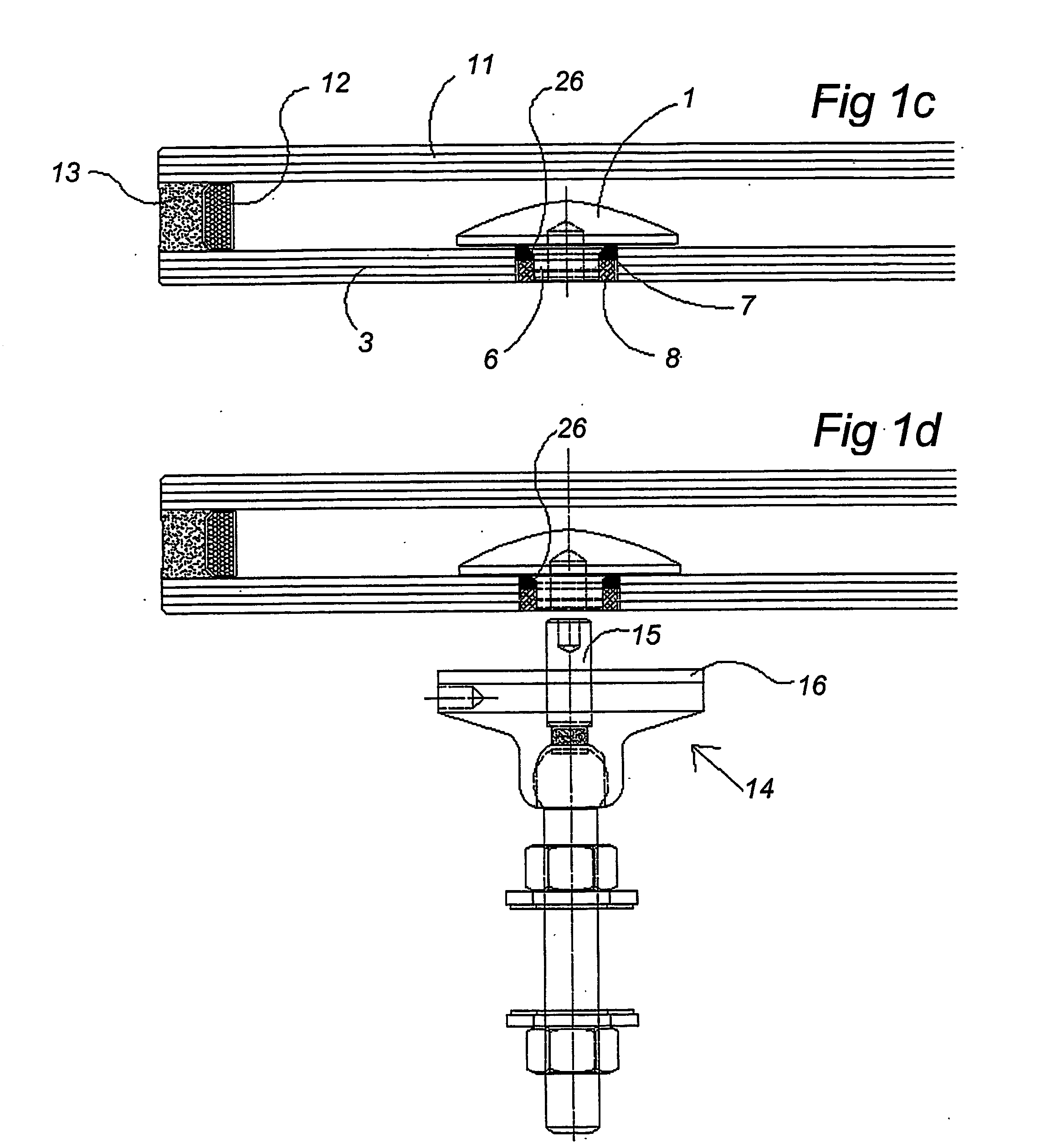

Internal Glass Holder

A glass element includes at least two glass slabs arranged in facing relationship with a peripheral spacer frame arranged between each pair of glass slabs, and holders for anchorage at selective points to a supporting structure. The holders, each one of which includes two clamping plates joined together via connectors, are mounted exclusively in apertures formed in the glass element slab that faces the supporting structure, i.e. the inner glass slab. One of the clamping plates of each holder fitting is formed with anchorage attachment points that are accessible from the outside, and the inner clamping plates are placed in abutment against the inner face of the inner glass slab prior to the assembly of the inner glass slab and the next glass slab, in such a manner that their connecting parts extend at most up to the outer mouth of the apertures. The connecting parts of the outer clamping plates, which outer clamping parts are applied to the external face of the inner glass slab in a later step, engage the connecting parts of the inner clamping plates and form the attachment points. Seals are arranged in said apertures in the inner glass slab and the inner clamping plates are attached to the inner face of the inner glass slab.

Owner:VIDA INT AB

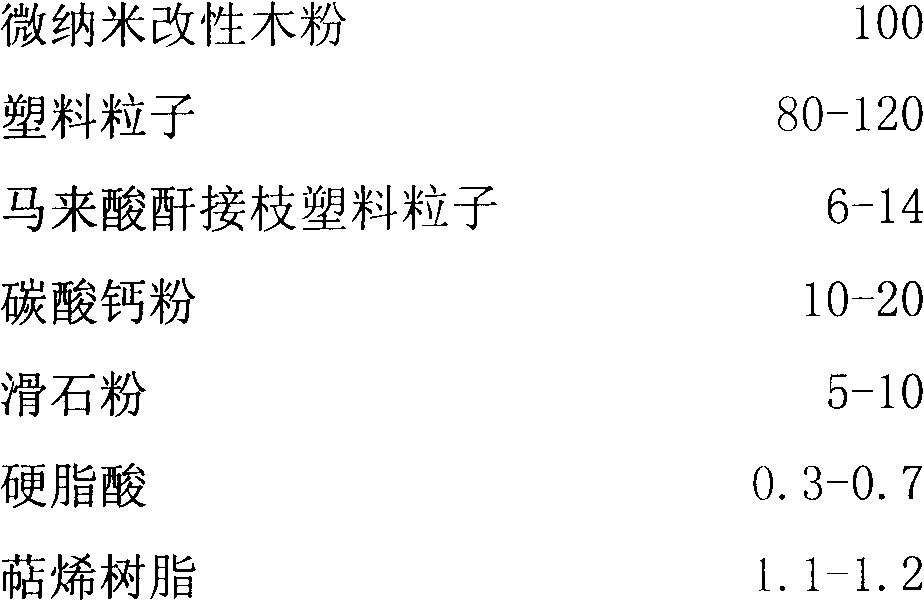

A kind of micro-nano reinforced plastic wood composite material board and preparation method thereof

The invention relates to a wood plastic material, in particular to a micro nanometer-enhanced wood plastic composite board and a preparation method thereof. The preparation method comprises the following steps of: hydrolyzing ethenyl triethoxy silane, and modifying wood powder by sealing pressurization reaction; mixing plastic granules, maleic anhydride grafting plastic granules, calcium carbonate powder and stearic acid, and extruding to obtain modified plastic granules; blending the modified plastic granules, the modifying wood powder, talcpowder, terpene resin and an antioxidant and granulating to obtain micro nanometer-enhanced wood plastic granules; and extruding the micro nanometer-enhanced wood plastic granules to form the micro nanometer-enhanced wood plastic board. The micro nanometer-enhanced wood plastic board can be recycled, is low in cost, has high mechanical properties and is an ideal material for replacing wood; and compared with the conventional wood material, the micro nanometer-enhanced wood plastic composite board has a longer service life, is a novel upgrading and updating product of the conventional wood plastic material, and can be widely applied in fields of traffic, buildings, decoration, municipal administration, gardens, packaging and the like.

Owner:江苏福瑞森塑木科技股份有限公司

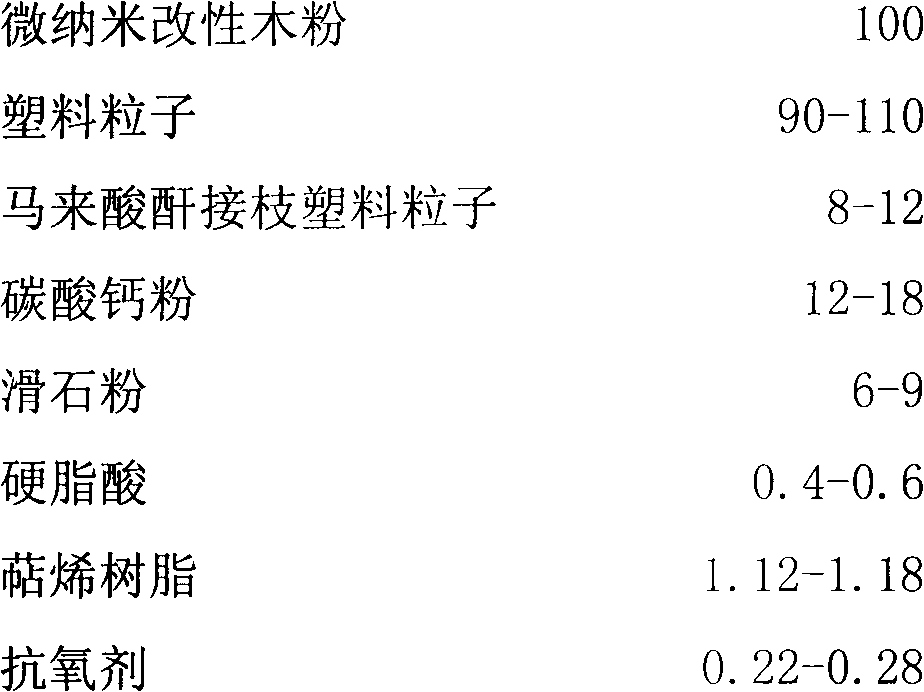

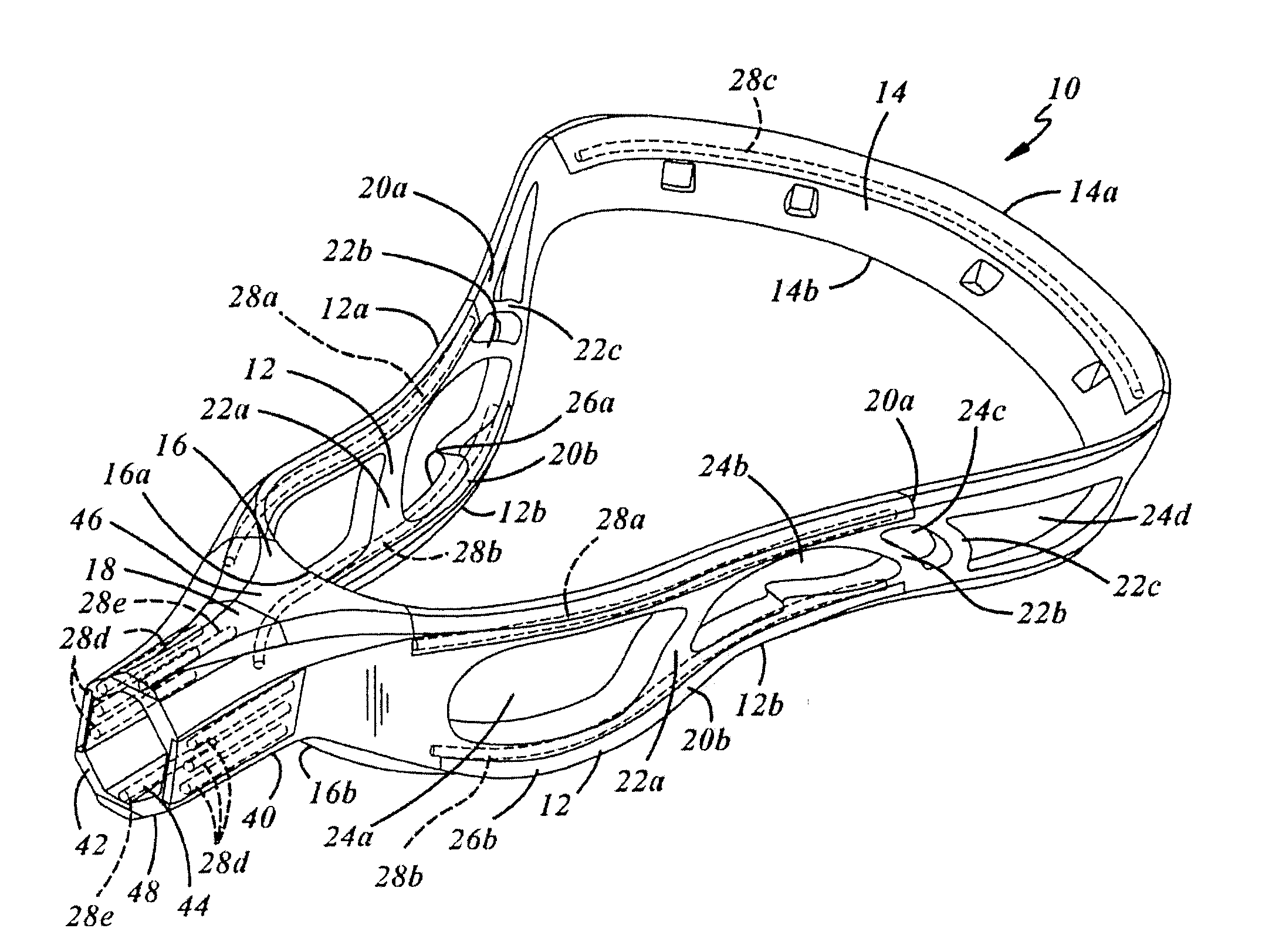

Reinforced lacrosse head

InactiveUS20070270255A1High strengthIncrease resistanceThrow gamesBall sportsEngineeringMechanical engineering

Owner:WARRIOR SPORTS INC

Lightweight plastic-wood composite sheet and preparation method thereof

The invention relates to a lightweight plastic-wood composite sheet and a preparation method thereof. The preparation method comprises the following steps of: firstly stirring PVC particles and tribasic lead sulfate evenly in a stirred tank, and then adding wood flour, LDPE-g-GMA, hollow glass beads, chlorinated polyethylene, ethylene bisstearamide and hard fatty acid butyl ester to the tank, heating up and stirring evenly, cooling and taking out the mixture, and then stirring the mixture evenly with baking soda and citric acid at room temperature, extruding out and molding. The lightweight plastic-wood sheet has the advantages of convenient production and manufacture, high degree of mechanization in the production process, low production cost, low density, light weight, easy installation and maintenance, less use of timber and plastic, turning waste into treasure, being recyclable and not destroyed by insects, no aging and discoloration as well as cracking, no buckling deformation and high impact strength, with the function of adsorbing gas. The lightweight plastic-wood sheet can be applied to a plurality of occasions such as office buildings, hotels and home offices, can be made into products such as photo frames, picture frames, foot lines, and hoisting and fastening boards, and can also be used as suspended beams, pergolas, and the like.

Owner:江苏森诺塑胶科技有限公司

High-strength micropore plastic-wood composite material panel and preparation method thereof

The invention discloses a high-strength micropore plastic-wood composite material panel and a preparation method thereof. The panel is prepared from benzylated fibrous wood powder, polyvinyl chloride plastic particles, p-toluenesulfonyl semicarbazide, N,N-dinitrosopentamethylene tetraamine, activated calcium carbonate powder, calcium stearate, lead sulfate tribasic, urea, salicylic acid, dibutyl phthalate and an antioxidant; the preparation method comprises the following steps: firstly preparing the fibrous wood powder from the wood powder by using a pulping method, preparing benzylated fibrous wood powder by modifying benzyl chloride, preparing the activated calcium carbonate by modifying calcium carbonate by using octadecanol polyoxyethylene ether sodium acetate, and then extruding a formed panel by using a step-by-step extrusion process. The panel disclosed by the invention is low in density, light in weight, large in rigidity, resistant in creep deformation, good in heat insulation and sound insulation, and convenient for transportation and mounting; the production manufacturing is convenient and environment-friendly, and the panel can be widely used for suspended ceilings, screens, wainscots, skirting lines, television background walls, door planks, racks and the like in the fields of building, traffic and decoration.

Owner:JIEYANG JIADA FOOTWEAR IND

Elastomer modified plastic-wood composite board and preparation method thereof

The invention relates to a plastic-wood material, particularly to an elastomer modified plastic-wood composite board and a preparation method thereof. Plastic particles, maleic anhydride grafted plastic particles, kaolin powder, hollow glass microspheres and stearic acid are placed in a mechanical stirring kettle to be stirred and then are extruded and granulated, so as to obtain modified plastic particles; and the modified plastic particles, wood powder, a polyolefin elastomer, a thermoplastic polyurethane elastomer and pigment are placed into the mechanical stirred kettle to be stirred and uniformly mixed, then are melted, blended and extrusion-molded and finally pass through a flat finish mold, so as to obtain the elastomer modified plastic-wood composite board. The elastomer modified plastic-wood composite board provided by the invention has the advantages as follows: the production-manufacturing is convenient, the degree of mechanization of the production process is higher, less labor is required, and the production cost is low; the consumption of plastics is low, environmental friendliness and creep deformation resistance are achieved, the strength and the rigidity are high, and the service life is longer; and the elastomer modified plastic-wood composite board can be widely applied to various fields such as transportation, decoration, municipal gardens and packaging.

Owner:G&S HUZHOU ENTERPRISES

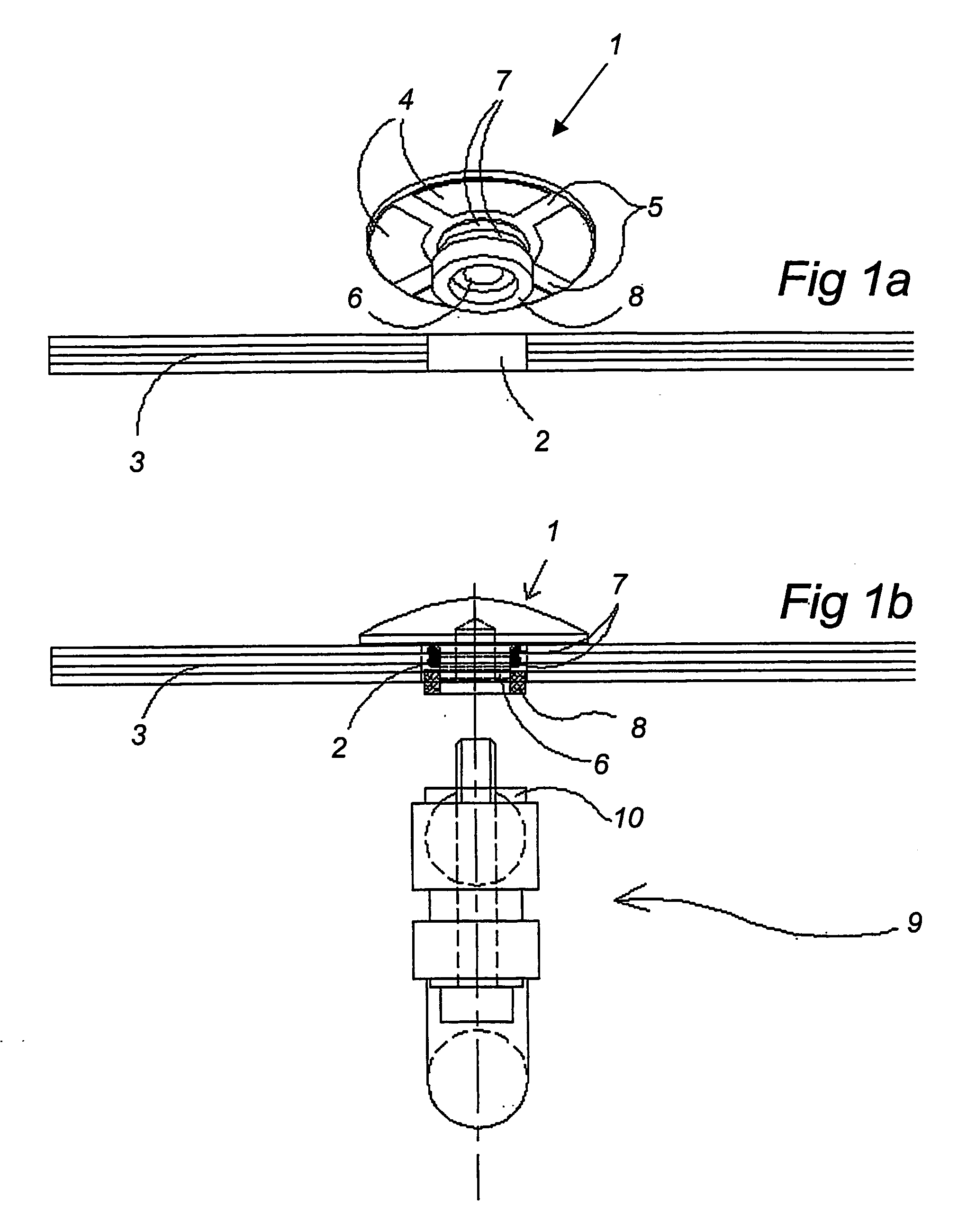

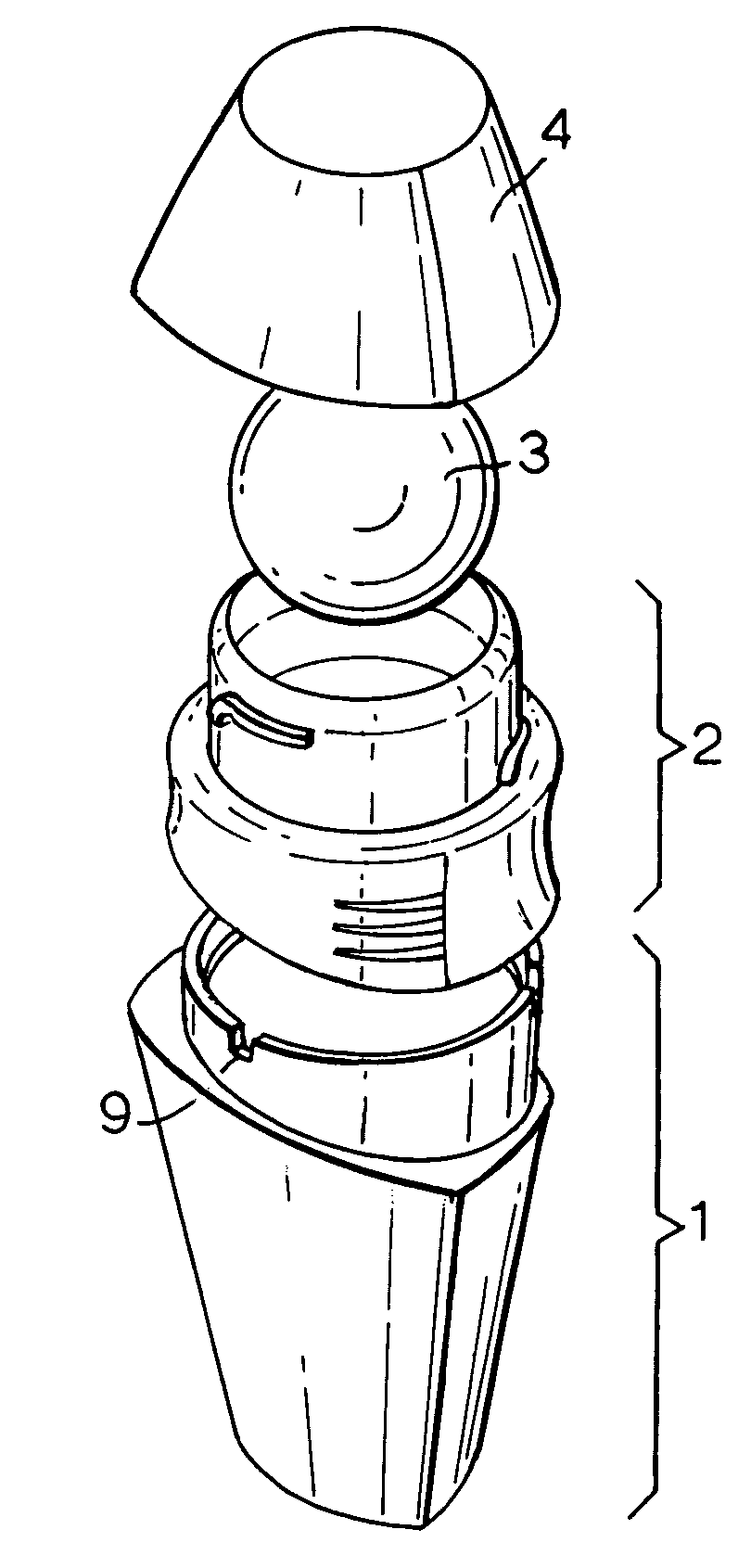

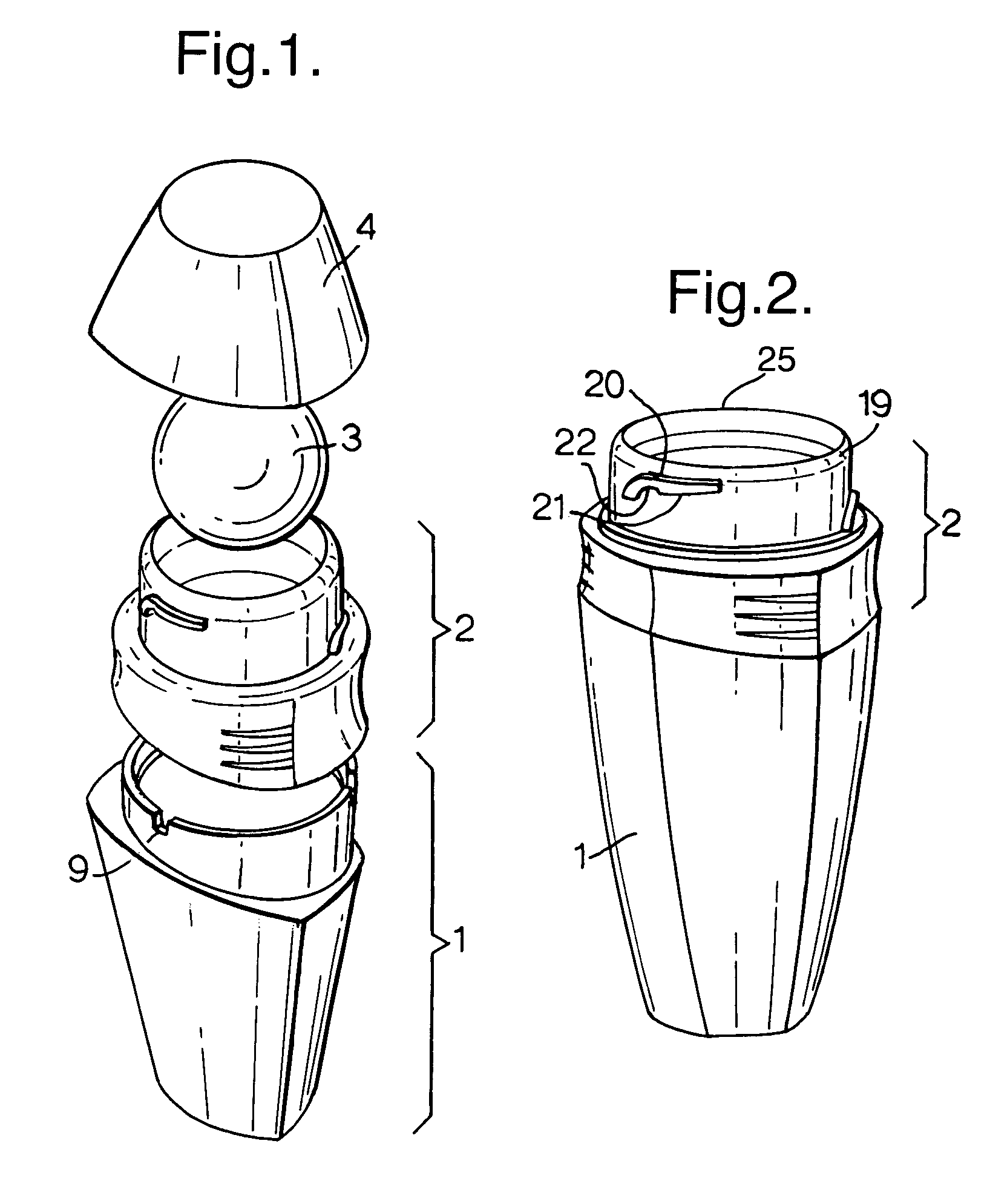

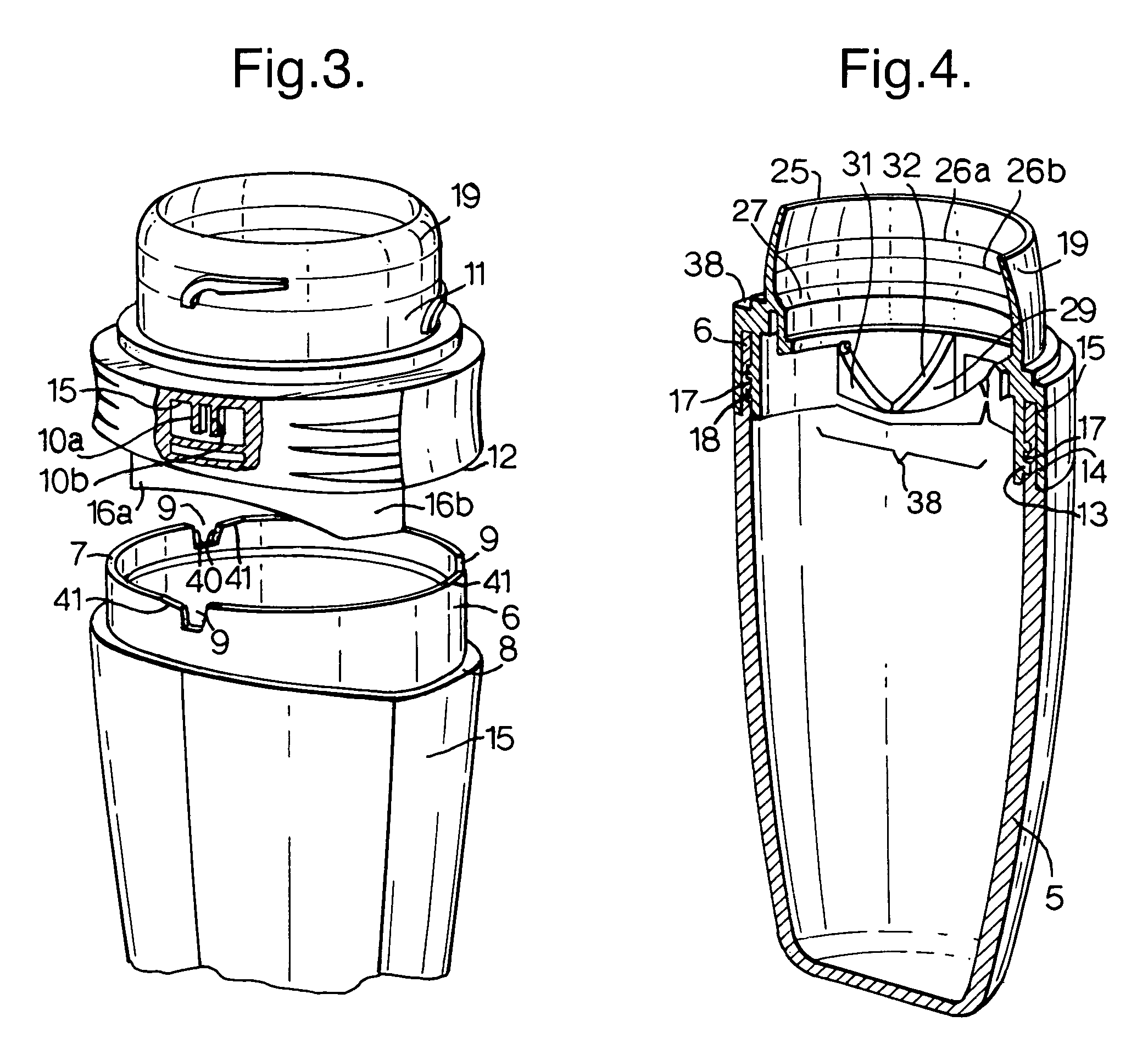

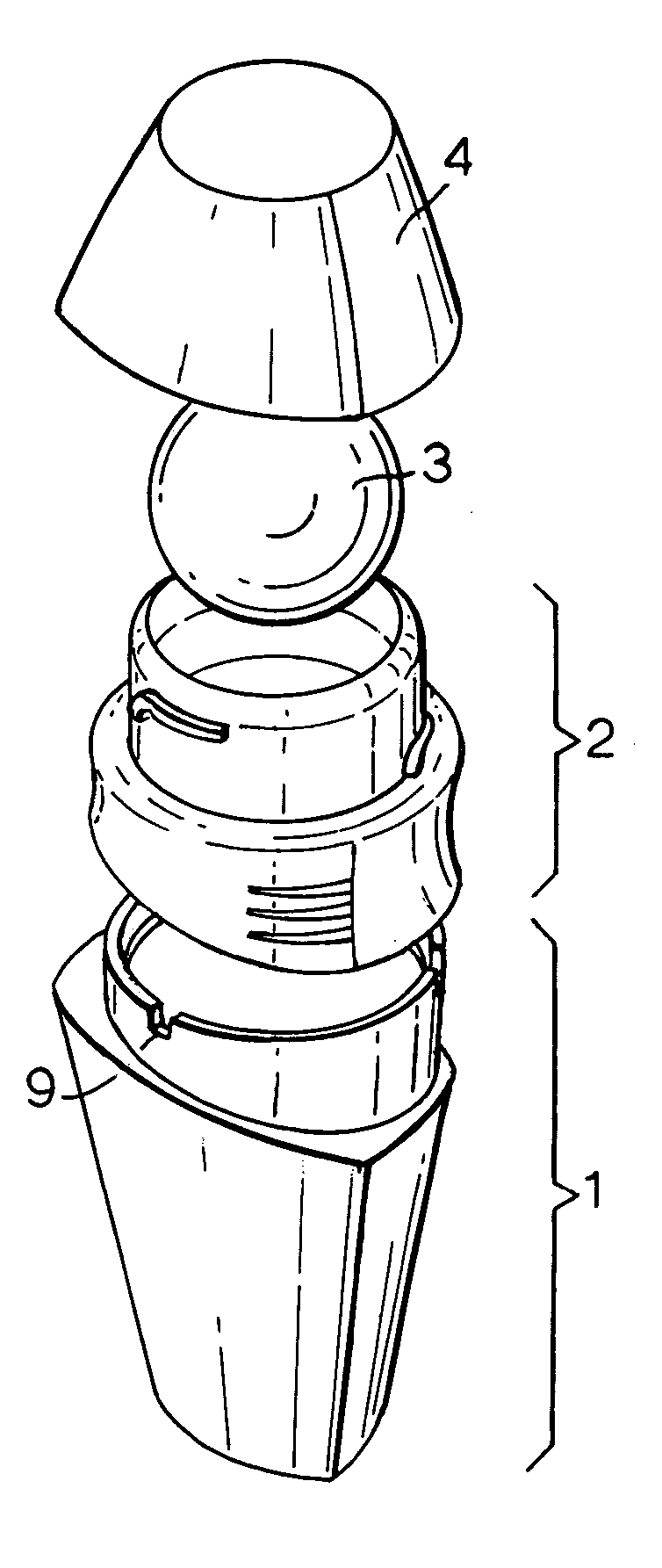

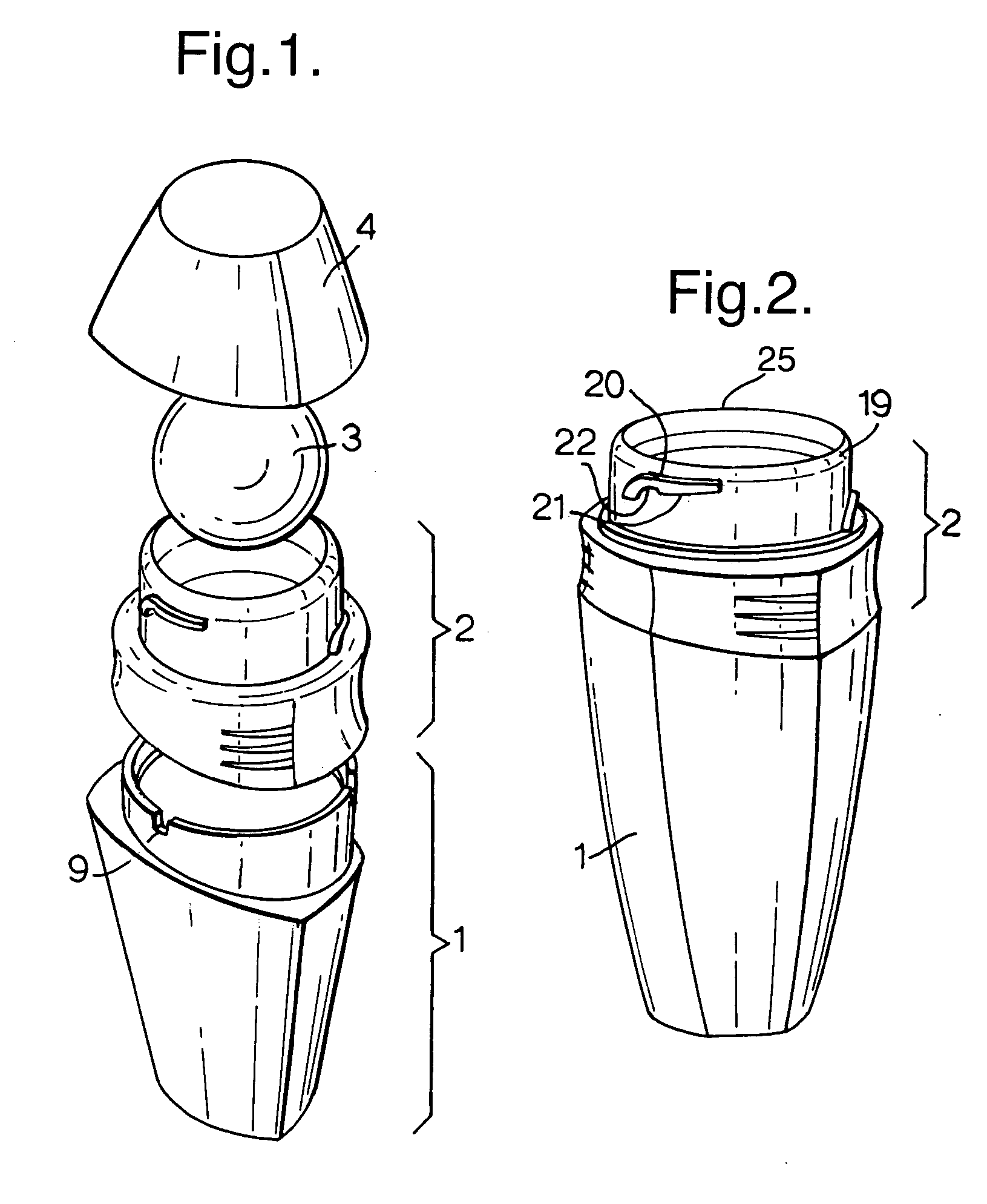

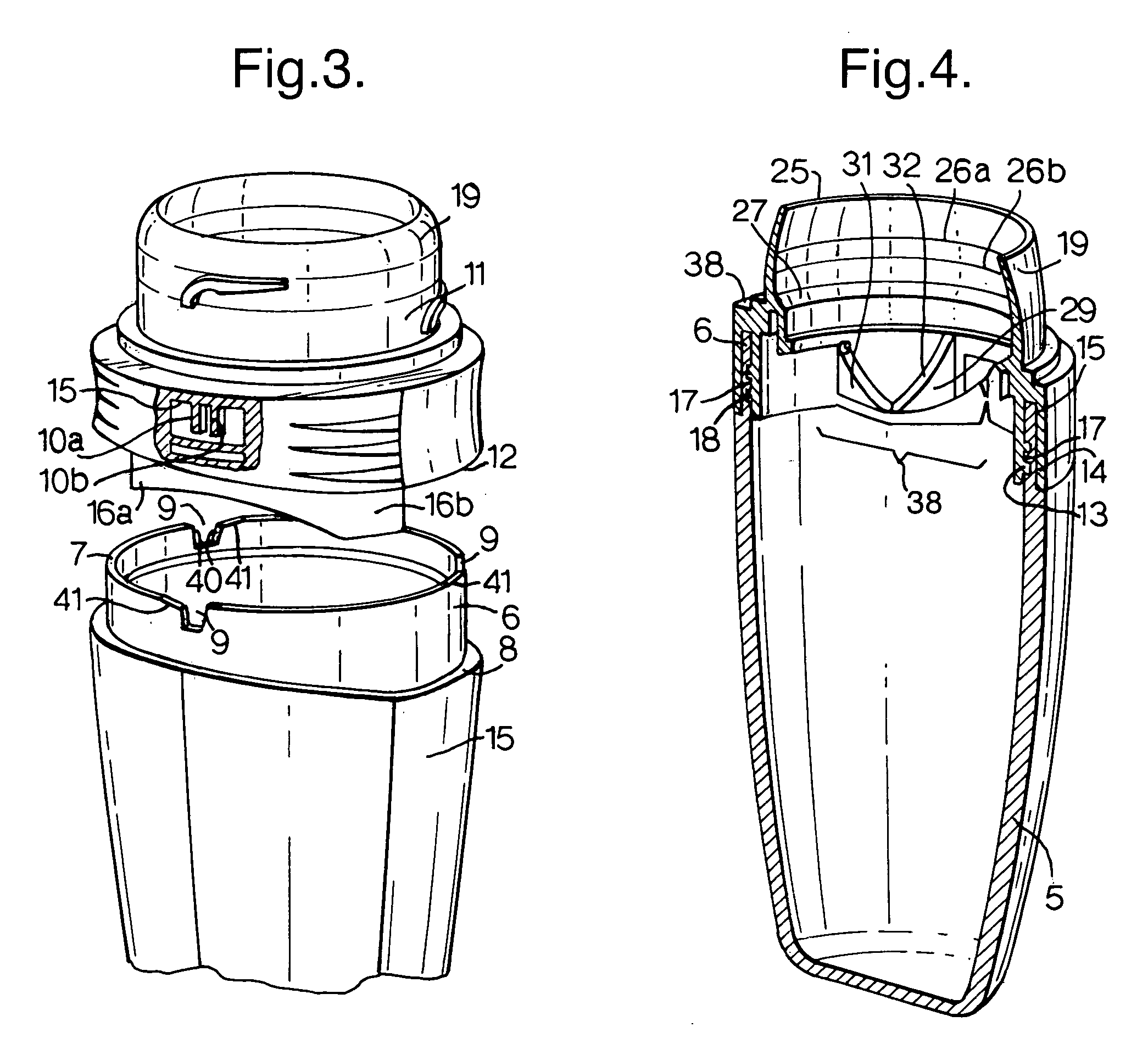

Fluid cosmetic dispenser

InactiveUS7674061B2Reduce riskLess plasticWriting connectorsLiquid transferring devicesAntiperspirantsEngineering

In cosmetic dispensers for fluids, such as for example deodorants or antiperspirants comprising a bottle, a flow regulator in a housing mounted on the bottle and a cap rotatably mounted on the bottle or particularly onto the flow regulator housing, there is a risk that the housing can part from the bottle or be moved out of alignment by fitting or removal of the cap. This problem can be ameliorated or eliminated by employing a plurality of sets of anti-rotation elements at or adjacent to the mouth of the bottle around its periphery, each set comprising a peg and a socket. Preferably, the housing is bifurcated inward of the flow regulator, one wall extending within the bottle and the other wall extending out side the wall, and desirably the bottle wall is of reduced wall thickness in the overlap so that the exterior of the bottle surface and housing surface can be flush at their line of contact.

Owner:CONOPCO INC D B A UNILEVER

Preparation method of base material for anion wall plates and floors capable of purifying indoor air

The invention discloses a preparation method of anion wall plates and floors capable of purifying indoor air. The preparation method comprises the steps of preparing materials, wherein polypropylene resin and a performance improving agent are weighed and put into a mixing machine; conducting heating and stirring, so that a material mixture is formed; raising the temperature of the material mixture, conducting stirring, and sending the material mixture into a cold mixing treatment machine for conducting slow stirring and temperature lowering; weighing other raw materials other than the polypropylene resin and the performance improving agent, and putting the materials into the mixing machine; conducting heating, raising the temperature, conducting stirring, and putting obtained materials into an extruder for pressure extrusion; and conducting cooling, traction and cutting on extruded sheets, so that finished products are obtained. The products manufactured through the method are high in surface brightness, free of clamminess, attractive in appearance, firm, durable, free of deformation, good in quality and wide in application scope and has good development prospect.

Owner:SHANDONG XINHAI NEW MATERIAL

Package assembly for wiper blade

ActiveUS20130105343A1Reduce widthLess plasticOther accessoriesRigid containersMechanical engineeringAutomotive engineering

A wiper package assembly for use in packaging a pre-curved wiper blade. The wiper package assembly generally includes a package and a pair of end caps fittable onto the wiper blade and into the package. The package and end caps may be configured to cooperatively hold the pre-curved wiper blade in an at least partially straightened condition. The end caps may be configured to engage the wiper blade without altering the shape of the wiper blade tip, thereby reducing the risk of the wiper tip becoming deformed during by the package. In one embodiment, the end caps are ambidextrous in the sense that identical end caps can be used on opposite ends of the wiper blade. The end cap may include two support slots configured to correspond with the shape of the opposite ends of an asymmetrical wiper blade.

Owner:DISPLAY PACK

Fluid cosmetic dispenser

InactiveUS20060018704A1Reduce riskLess plasticWriting connectorsLiquid transferring devicesAntiperspirantsBottle cap

In cosmetic dispensers for fluids, such as for example deodorants or antiperspirants comprising a bottle, a flow regulator in a housing mounted on the bottle and a cap rotatably mounted on the bottle or particularly onto the flow regulator housing, there is a risk that the housing can part from the bottle or be moved out of alignment by fitting or removal of the cap. This problem can be ameliorated or eliminated by employing a plurality of sets of anti-rotation elements at or adjacent to the mouth of the bottle around its periphery, each set comprising a peg and a socket. Preferably, the housing is bifurcated inward of the flow regulator, one wall extending within the bottle and the other wall extending out side the wall, and desirably the bottle wall is of reduced wall thickness in the overlap so that the exterior of the bottle surface and housing surface can be flush at their line of contact.

Owner:CONOPCO INC D B A UNILEVER

Anti-aging wood-plastic composite material board and preparation method thereof

The invention relates to an anti-aging wood-plastic composite material board and a preparation method of the board. The preparation method comprises the steps of: firstly, evenly stirring plastic particles, diisopropylbenzene peroxide, nano-titanium dioxide, antioxidant, antioxidant synergist, light stabilizer, basic magnesium sulfate whisker, stearic acid and oxidized polyethylene; carrying out melt blending and pelleting by adopting an extruder to obtain modified plastic particles; and then stirring the modified plastic particles, wood powder and pigment, and carrying out melt blending and extruding forming by adopting the extruder to obtain the anti-aging wood-plastic composite material board. The anti-aging wood-plastic composite material board is convenient to produce and manufacture, low in cost, less in plastic consumption and wood consumption, environment-friendly and high in modulus and rigidity, does not easily cause buckling deformation, and is free from cracking and damage by worms, resistant in ultraviolet light and thermal oxidizing aging, free from color fading and decomposition and long in service life. The anti-aging wood-plastic composite material board can be used as an open-air table and chair, a stool, a picnic table, a flower box, a guardrail, a sign and the like to be widely applied to occasions such as a park, a court, municipal administration, a dock and the like.

Owner:G&S HUZHOU ENTERPRISES

Reinforced lacrosse head and related method of manufacture

InactiveUS20100000656A1LessShorten the timeSynthetic resin layered productsLaminationEngineeringAcoustic wave

A reinforced lacrosse head having improved strength can include the following frame elements: a pair of opposing sidewalls each having a top end and a bottom end, a scoop extending between the sidewalls, a base extending between the bottom ends of the sidewalls, and a throat extending from the base for attachment to a lacrosse handle. The head can include at least one reinforcement member that is located at least partially in a frame element. The frame element can be constructed from two or more parts that are sonic welded or hot plate welded together around at least a portion of the reinforcement member. Methods of sonic welding or hot plate welding components of a reinforced frame element also are provided.

Owner:WARRIOR SPORTS INC

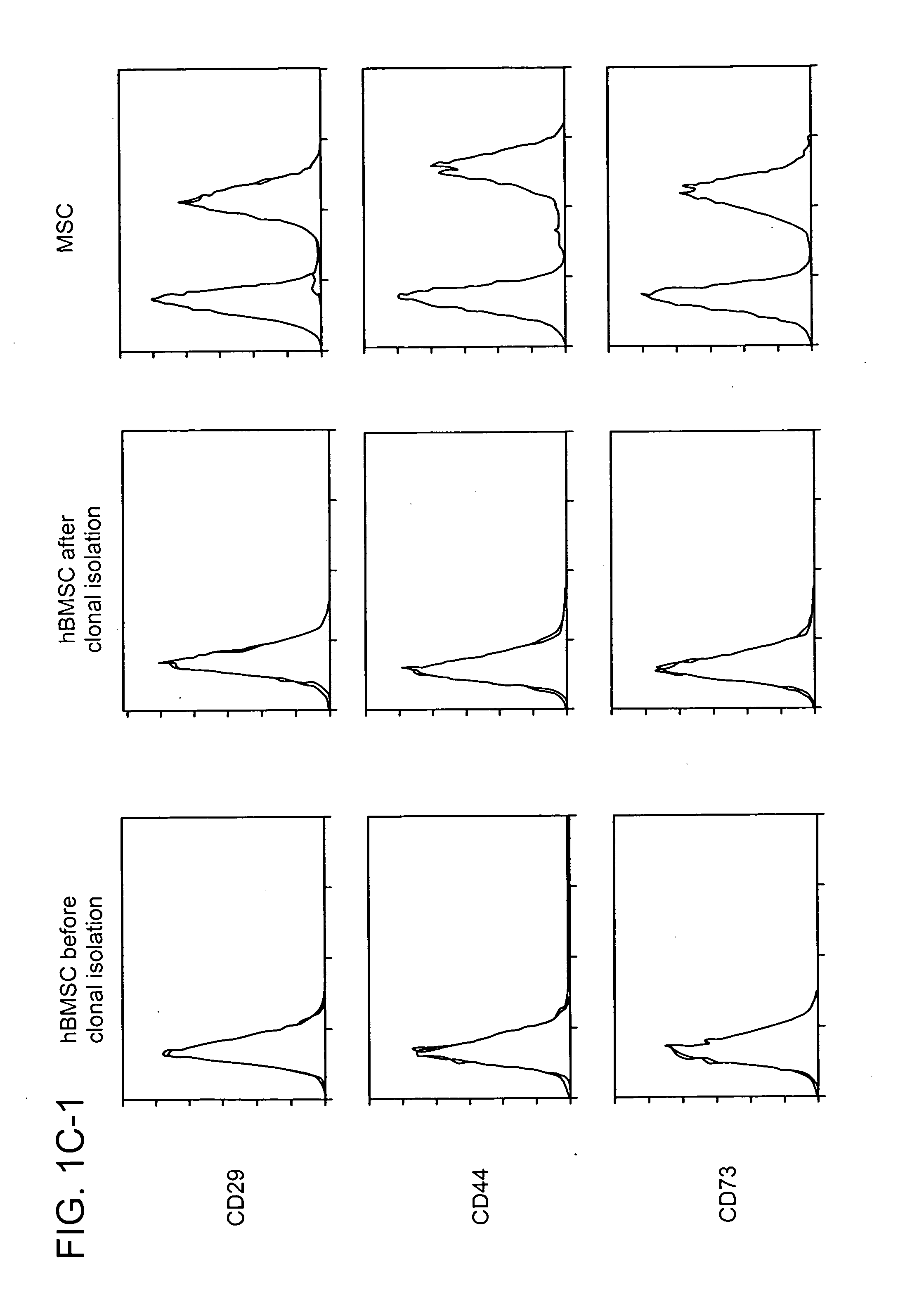

Novel multipotent stem cells and use thereof

InactiveUS20070253937A1Reduce severityPrevent and treat and reduce severityBiocideArtificial cell constructsSmooth muscleCell marker

Disclosed is an isolated bone marrow stem cell (BMSC) having undetectable or low levels of selected cell markers including those typical of endothelial, neuronal and smooth muscle cells. Also disclosed are grafts and pharmaceutical products that include such cells. Methods of making the BMSCs are also provided. The invention has a wide spectrum of useful applications including use in the prevention and treatment of cardiovascular disease.

Owner:STEWARD RES & SPECIALTY PROJECTS

Preparation method of negative ion plastic interior decorative part with in-car air purification function

The invention discloses a preparation method of a negative ion plastic interior decorative part with in-car air purification function. The preparation method comprises the following steps: preparing materials, weighing polypropylene resin and a performance improver and pouring the materials into a mixer, heating and stirring to form a mixed material, heating and stirring the mixed material, sending the mixed material into a cold-mixing processor and slowly stirring and cooling, weighing other raw materials except the polypropylene resin and the performance improver and pouring the materials into a high temperature mixer, heating and stirring, putting the material obtained into an injection molding machine and a mould and carrying out injection moulding to prepare a finished product. The prepared automobile interior decorative product has high surface brightness, is not sticky, has beautiful appearance, is solid and durable and will not deform, has good quality, has a wide range of application, and has a good development prospect.

Owner:SHANDONG XINHAI NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com