Micro-foaming wood plastic composite sheet and preparation method thereof

A wood-plastic composite material and micro-foaming technology, applied in the field of wood-plastic composite materials, can solve the problems of high price and high density, and achieve the effect of low cost, low density and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

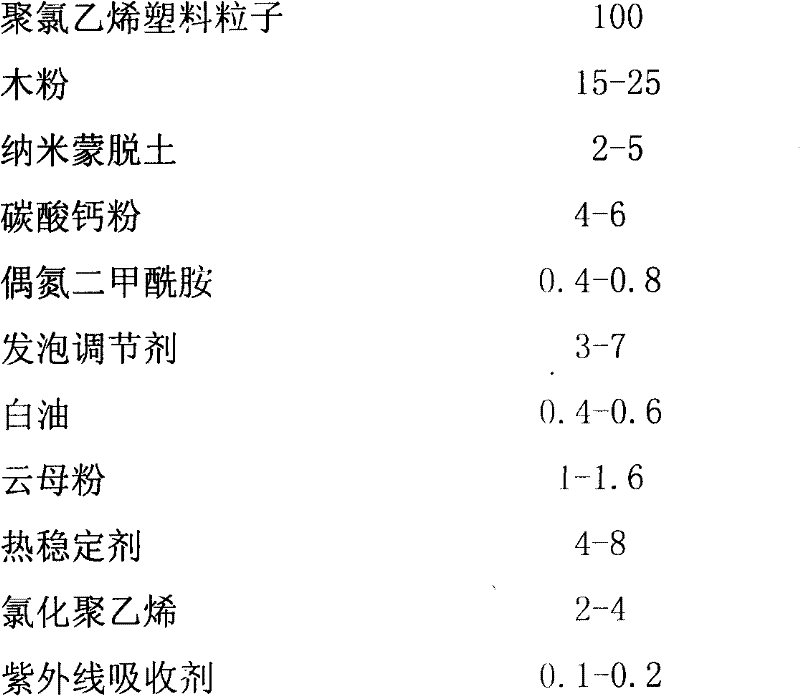

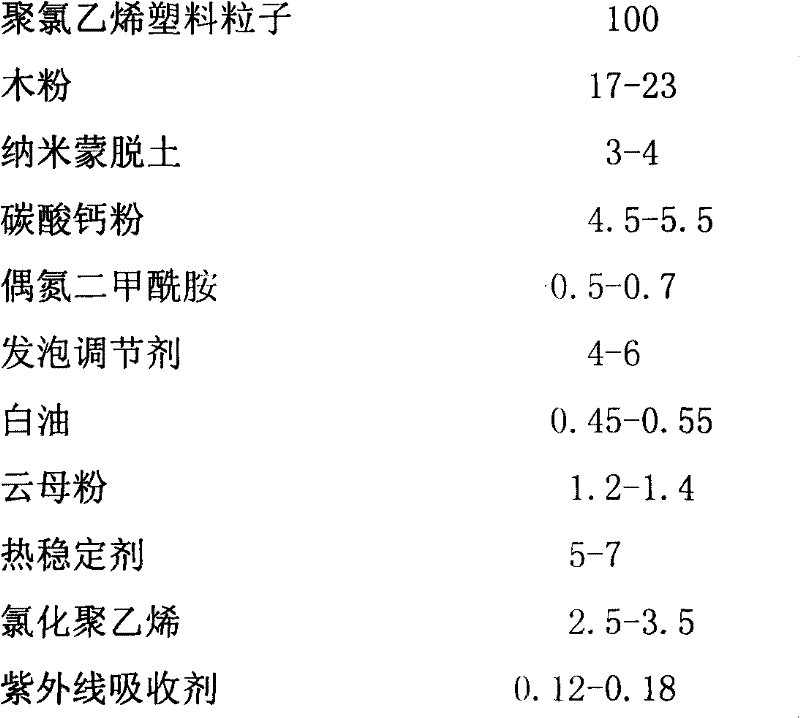

Method used

Image

Examples

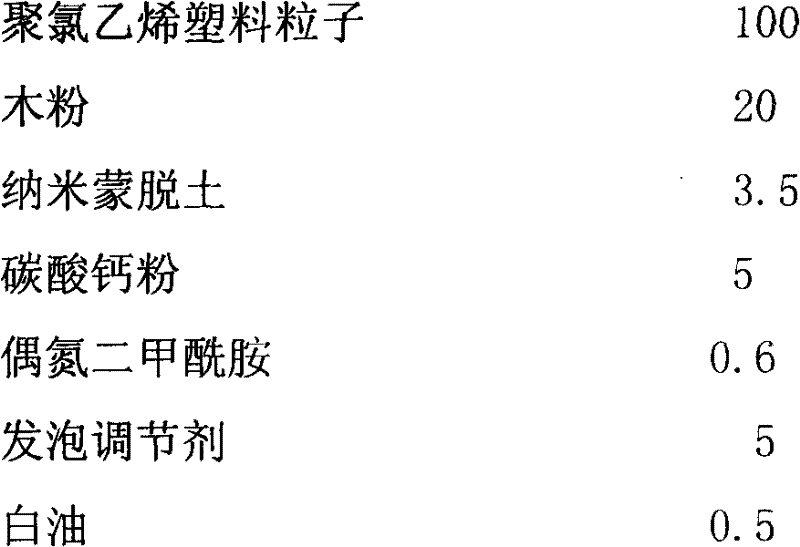

Embodiment 1

[0028] PVC plastic particles 100, wood flour (100 mesh) 20, nano-montmorillonite (35nm) 3.5,

[0029] Calcium carbonate powder (1200 mesh) 5, azodicarbonamide 0.6, foam regulator 5,

[0030] White oil 0.5, mica powder (1250 mesh) 1.3, heat stabilizer 6,

[0031] Chlorinated polyethylene 3, UV absorber (UV531) 0.15.

[0032] (1) take each raw material by formula quantity;

[0033] (2) Polyvinyl chloride plastic particles, nano-montmorillonite, calcium carbonate powder, white oil, heat stabilizer, and mica powder were placed in a mechanical stirring tank and stirred for 8 minutes, then extruded and granulated, and the granulated extrusion temperature was 170°C to obtain modified plastic particles;

[0034] (3) Place the above-mentioned modified plastic particles, wood powder, azodicarbonamide, foam regulator, chlorinated polyethylene, and ultraviolet absorber in a mechanically stirred tank and mechanically stir again for 4 minutes;

[0035] (4) After mixing, use an extruder ...

Embodiment 2

[0037] Polyvinyl chloride plastic particles 100, wood powder (80 mesh) 15, nanometer montmorillonite (20nm) 2,

[0038] Calcium carbonate powder (800 mesh) 4, azodicarbonamide 0.4, foam regulator 3,

[0039] White oil 0.4, mica powder (1250 mesh) 1, heat stabilizer 4,

[0040] Chlorinated polyethylene 2, UV absorber (L770) 0.1.

[0041] (1) take each raw material by formula quantity;

[0042] (2) Polyvinyl chloride plastic particles, nano-montmorillonite, calcium carbonate powder, white oil, heat stabilizer, and mica powder were placed in a mechanical stirring tank and stirred for 6 minutes, then extruded and granulated, and the granulated extrusion temperature was 160°C to obtain modified plastic particles;

[0043] (3) The above-mentioned modified plastic particles, wood flour, azodicarbonamide, foam regulator, chlorinated polyethylene, and ultraviolet absorber are placed in a mechanically stirred tank and mechanically stirred again for 3 minutes;

[0044] (4) After mixi...

Embodiment 3

[0046] PVC plastic particles 100, wood powder (120 mesh) 25, nanometer montmorillonite (50nm) 5,

[0047] Calcium carbonate powder (1500 mesh) 6, azodicarbonamide 0.8, foam regulator 7,

[0048] White oil 0.6, mica powder (2500 mesh) 1.6, heat stabilizer 8,

[0049] Chlorinated polyethylene 4, ultraviolet absorber (UV531) 0.2.

[0050] (1) take each raw material by formula quantity;

[0051] (2) Polyvinyl chloride plastic particles, nano-montmorillonite, calcium carbonate powder, white oil, heat stabilizer, and mica powder were placed in a mechanical stirring tank and stirred for 10 minutes, then extruded and granulated, and the granulated extrusion temperature was 180°C to obtain modified plastic particles;

[0052] (3) Place the above-mentioned modified plastic particles, wood flour, azodicarbonamide, foam regulator, chlorinated polyethylene, and ultraviolet absorber in a mechanically stirred tank and mechanically stir again for 5 minutes;

[0053] (4) After mixing, use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com