High-strength plastic wood dalle and preparation method thereof

A decorative board and high-strength technology, applied in the field of high-strength plastic wood decorative board and its preparation, can solve the problems of long-term use, such as bending, shortening the service life, and limiting the scope of use, achieving low production costs, reducing product raw material costs, The effect of less decrease in mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

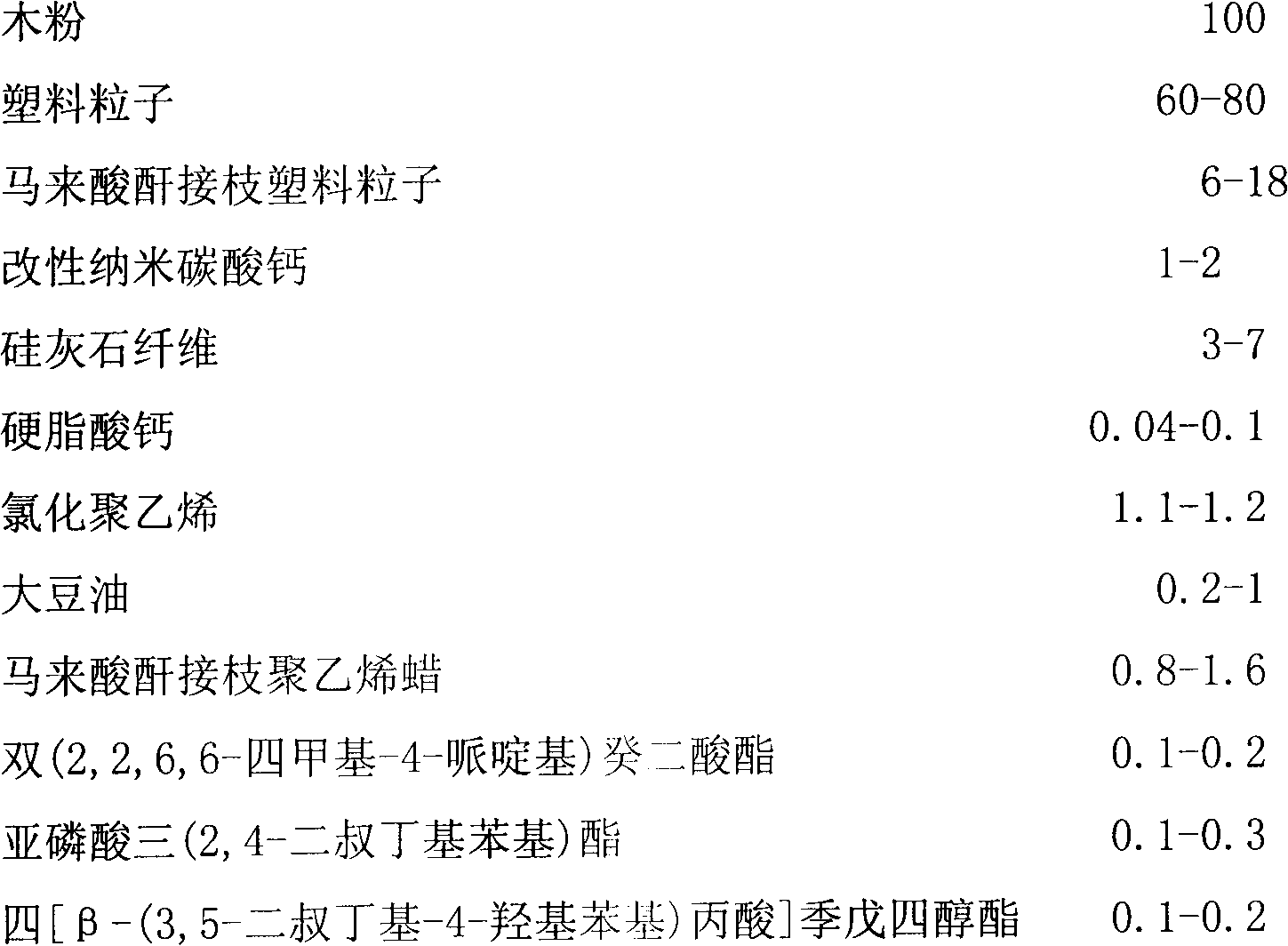

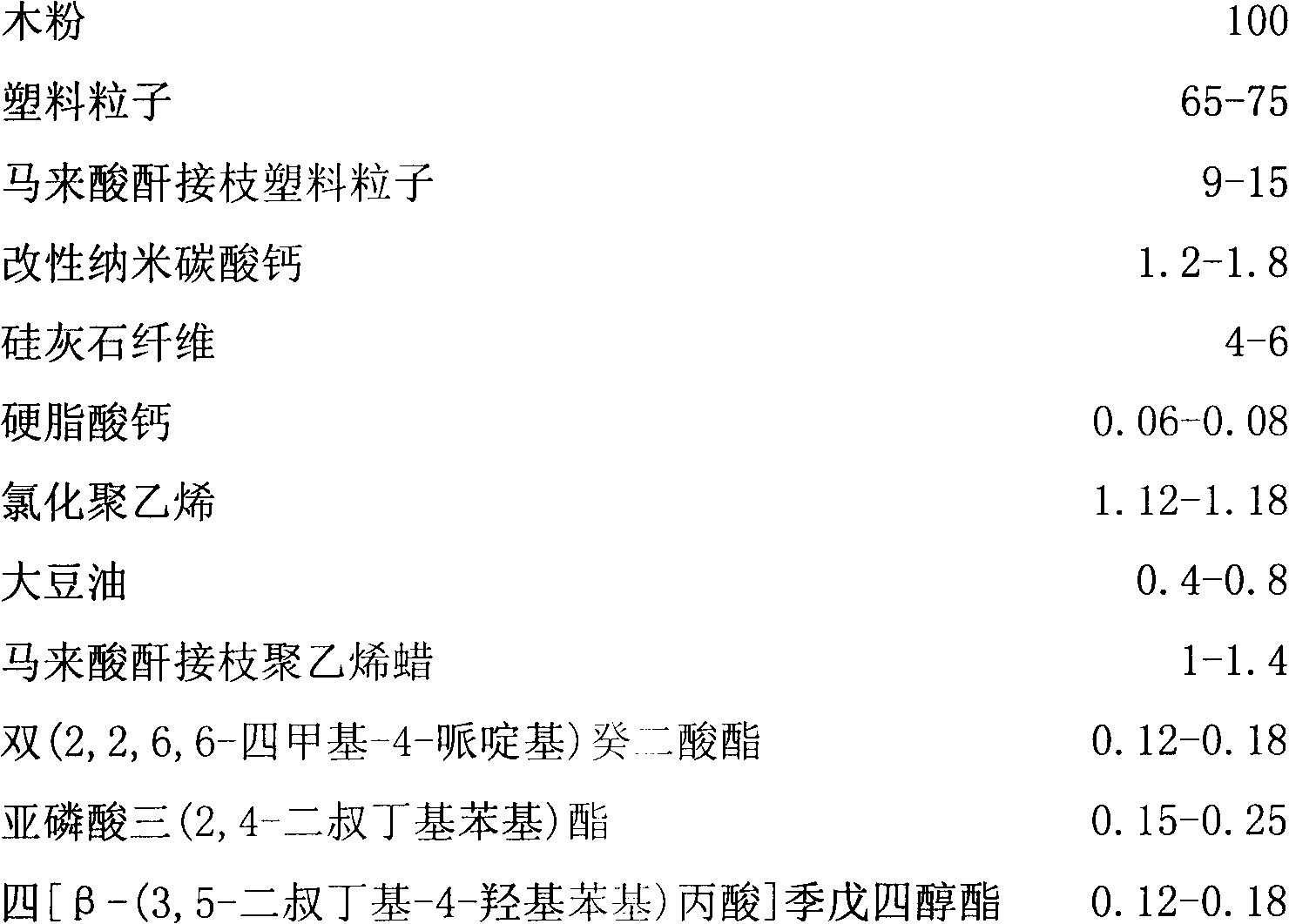

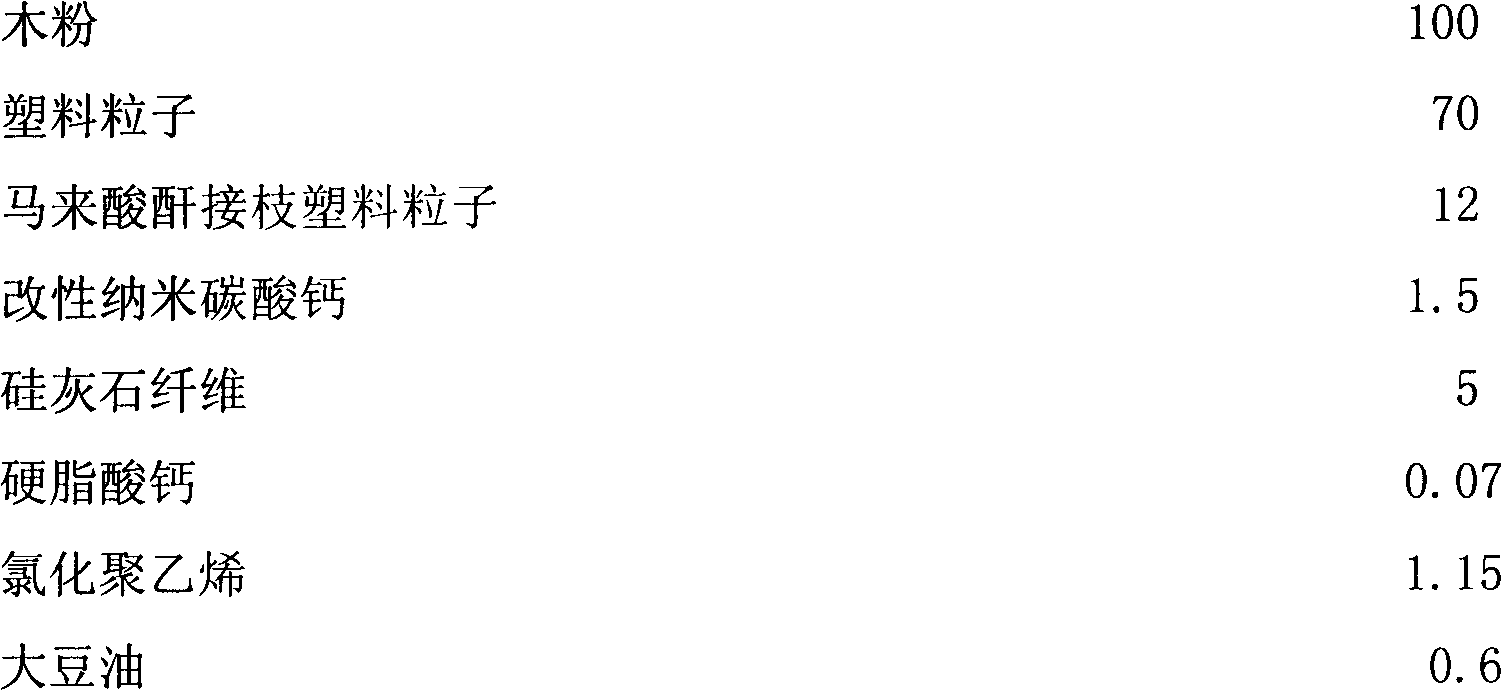

[0030]

[0031] (1) Mix the silane coupling agent and water uniformly in a weight ratio of 1:3, wherein water is the solvent.

[0032] (2), the nano-calcium carbonate and the diluted silane coupling agent are mixed uniformly by weight ratio of 100:4, and at 60° C., vacuum-dried for 4.5 hours to make modified nano-calcium carbonate;

[0033] (3), take each raw material by formula quantity;

[0034] (4) Put a sufficient amount of water in the ultrasonic container, immerse the wood powder and modified nano-calcium carbonate in it, stir evenly by hand, turn on the ultrasonic device with a frequency of 30kHz, process for 12.5 minutes, turn off the ultrasonic generator, and cool For 45 minutes, turn on the ultrasonic device again, and treat for 12.5 minutes, use ultrasonic waves to make the modified nano-calcium carbonate enter the cell cavity of the wood powder, stop the ultrasonic treatment, take out the wood powder, dry, and sieve to obtain the nano-modified wood powder;

[0...

Embodiment 2

[0040]

[0041]

[0042] (1) Mix the silane coupling agent and water uniformly in a weight ratio of 1:1, wherein water is the solvent.

[0043] (2), the nano-calcium carbonate and the diluted silane coupling agent are mixed evenly by weight ratio 100:2, and at 40 DEG C, vacuum-dried for 3 hours to make modified nano-calcium carbonate;

[0044] (3), take each raw material by formula quantity;

[0045] (4) Put a sufficient amount of water in the ultrasonic container, immerse the wood powder and modified nano-calcium carbonate in it, stir evenly by hand, turn on the ultrasonic device with a frequency of 20kHz, process for 10 minutes, turn off the ultrasonic generator, and cool After 30 minutes, turn on the ultrasonic device again, and process for 10 minutes, and use ultrasonic waves to make the modified nano-calcium carbonate enter the cell cavity of the wood powder. After stopping the ultrasonic treatment, take out the wood powder, dry, and sieve to obtain nano-modified wo...

Embodiment 3

[0051]

[0052] (1) Mix the silane coupling agent and water uniformly at a weight ratio of 1:5, wherein water is the solvent.

[0053] (2), the nano-calcium carbonate and the diluted silane coupling agent are mixed evenly in a weight ratio of 100:6, and vacuum-dried for 6 hours at 80° C. to make modified nano-calcium carbonate;

[0054] (3), take each raw material by formula quantity;

[0055] (4) Put a sufficient amount of water in the ultrasonic container, immerse the wood powder and modified nano-calcium carbonate in it, stir it manually, turn on the ultrasonic device with a frequency of 40kHz, process for 15 minutes, turn off the ultrasonic generator, and cool After 60 minutes, turn on the ultrasonic device again, and process for 15 minutes, and use ultrasonic waves to make the modified nano-calcium carbonate enter the cell cavity of the wood powder. After stopping the ultrasonic treatment, take out the wood powder, dry, and sieve to obtain the nano-modified wood powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com