A kind of micro-nano reinforced plastic wood composite material board and preparation method thereof

A composite material, micro-nano technology, applied in the field of plastic-wood composite materials, can solve the problems of low natural fiber reinforcement effect, large polarity difference, poor interface compatibility, etc., to achieve convenient production and manufacturing, reduce the amount of plastic, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]

[0030] (1) Weigh 1 part of vinyltriethoxysilane, mix vinyltriethoxysilane and water uniformly at a weight ratio of 1:80, wherein water is the solvent, and adjust the pH value of the aqueous solution to 4.5.

[0031] (2) Weigh the wood flour according to the weight ratio of wood flour and vinyltriethoxysilane 100:2, add it to the aqueous solution of vinyltriethoxysilane, mix well, seal and pressurize, the pressure is 2MPa, and react After 4 hours, the pressure was released, the wood powder was taken out, and washed repeatedly with tap water until the wood powder was neutral and dried to obtain micro-nano modified wood powder;

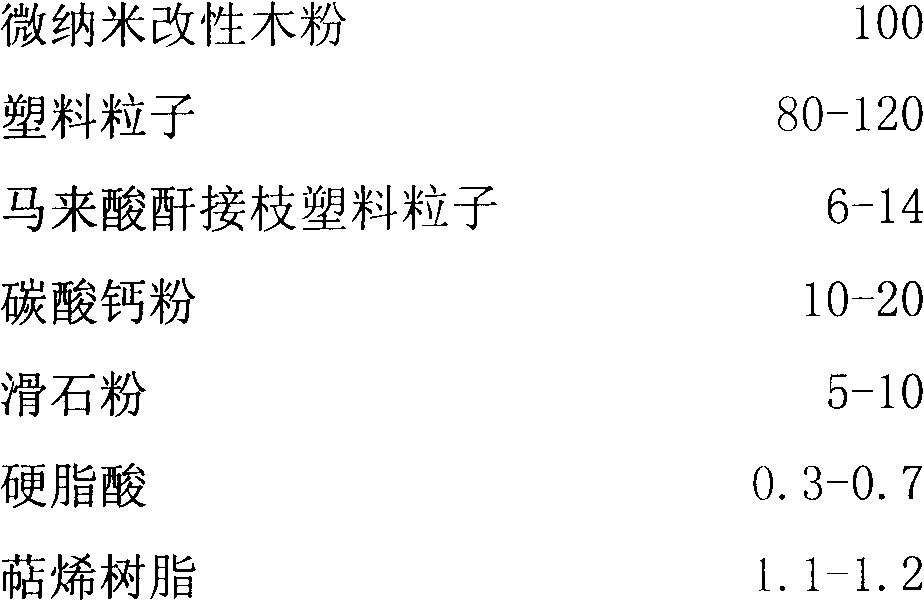

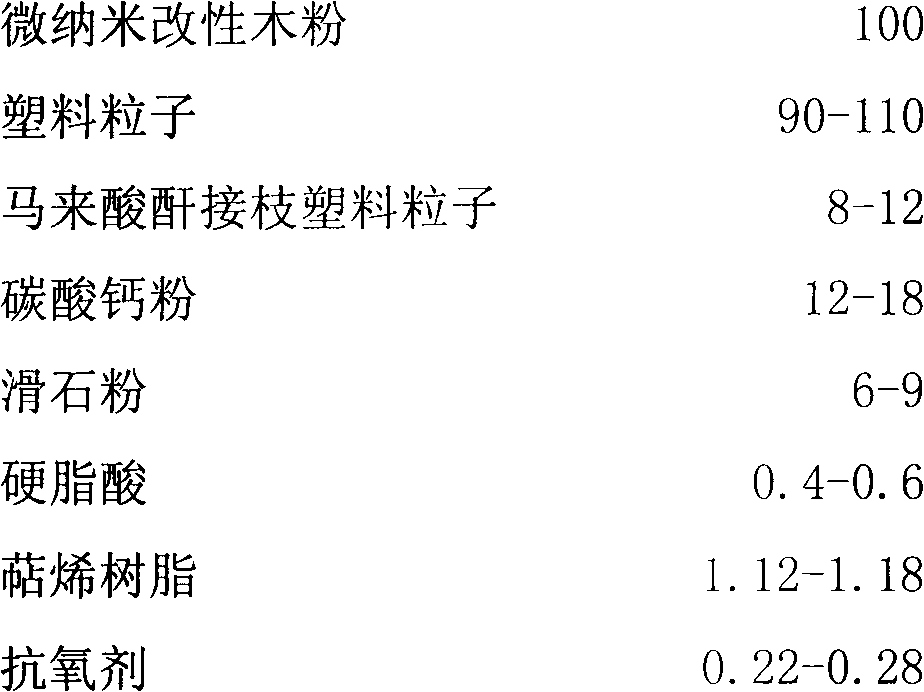

[0032] (3), take each raw material by the weight proportion amount of formula;

[0033] (4), plastic particles, maleic anhydride grafted plastic particles, calcium carbonate powder, and stearic acid were placed in a mechanical stirring tank and stirred for 2 minutes, extruded and granulated, the barrel temperature of the extruder was 180°C, a...

Embodiment 2

[0038]

[0039] (1) Weigh 1 part of vinyltriethoxysilane, mix vinyltriethoxysilane and water uniformly at a weight ratio of 1:60, wherein water is the solvent, and adjust the pH value of the aqueous solution to 4.

[0040] (2) Weigh the wood flour according to the weight ratio of wood flour and vinyltriethoxysilane 100:1, add it to the aqueous solution of vinyltriethoxysilane, mix well, seal and pressurize, the pressure is 1MPa, and react After 3 hours, the pressure was released, the wood powder was taken out, and washed repeatedly with tap water until the wood powder was neutral and dried to obtain micro-nano modified wood powder;

[0041] (3), take each raw material by the weight proportion amount of formula;

[0042] (4), plastic particles, maleic anhydride grafted plastic particles, calcium carbonate powder, and stearic acid are placed in a mechanical stirring tank and stirred for 1 minute, extruded and granulated, the barrel temperature of the extruder is 160 ° C, and ...

Embodiment 3

[0047]

[0048](1) Weigh 1 part of vinyltriethoxysilane, mix vinyltriethoxysilane and water uniformly at a weight ratio of 1:100, wherein water is the solvent, and adjust the pH value of the aqueous solution to 5.

[0049] (2) Weigh the wood flour according to the weight ratio of wood flour and vinyltriethoxysilane 100:3, add it to the aqueous solution of vinyltriethoxysilane, mix well, seal and pressurize, the pressure is 3MPa, and react After 5 hours, the pressure was released, the wood powder was taken out, and washed repeatedly with tap water until the wood powder was neutral and dried to obtain micro-nano modified wood powder;

[0050] (3), take each raw material by the weight proportion amount of formula;

[0051] (4), plastic particles, maleic anhydride grafted plastic particles, calcium carbonate powder, and stearic acid were placed in a mechanical stirring tank and stirred for 3 minutes, extruded and granulated, the barrel temperature of the extruder was 200°C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com