Compound film for decoration with tridimensional multicolor pattern

A color pattern and composite film technology, applied in the direction of special decorative structures, decorative arts, embossed ornaments, etc., can solve the problems of complicated process, difficult quality assurance, increased production cost, etc., and achieve simple production process, rich color changes, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

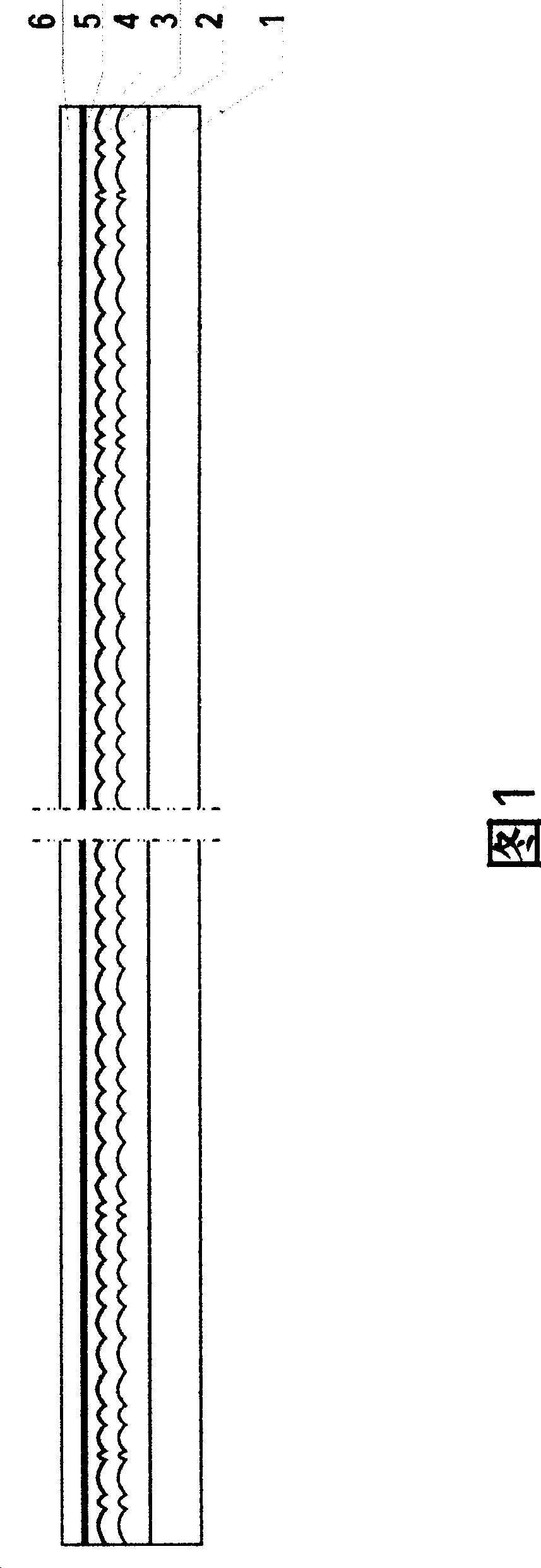

[0020] As shown in Figures 1 to 2, 1 in the figure is a flat plastic bottom film layer of PET material, and its thickness is between 0.1 and 0.3 mm. Between the plastic bottom film layers 1, a hot melt layer 2 is sequentially arranged. Concave-convex three-dimensional pattern metal coating layer 3, transparent double-sided adhesive layer 4 and fully transparent film layer 6 with characters and patterns 5.

[0021] The above-mentioned hot-sol layer 2 is a convex-concave hot-melt layer that is correspondingly bonded to the metal coating layer 3 with a concave-convex three-dimensional pattern. The thickness of the hot-melt glue is required to be between 0.05 and 0.3 mm, depending on different product requirements and three-dimensional convex requirements. The higher the three-dimensional protrusions, the thicker the adhesive layer is. Use the pre-prepared mold master plate, after high-temperature pressing, the hot melt melts at high temperature, and fills all the convex-concave th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com