Gangue foam concrete building block for realizing self heat insulation of walls

A technology of foam concrete and coal gangue, applied in the field of building materials, to achieve the effects of low cost, saving limestone mineral resources, and environmental protection of limestone mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

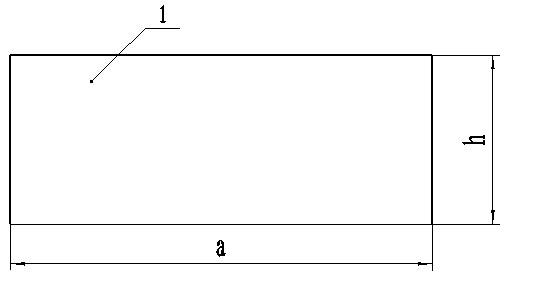

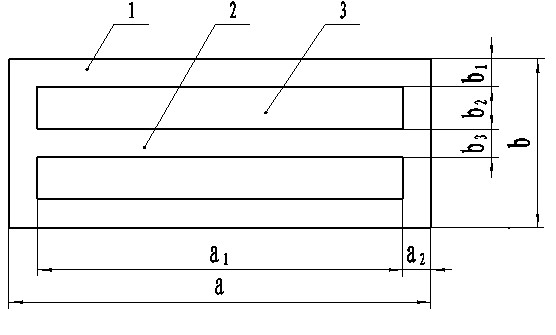

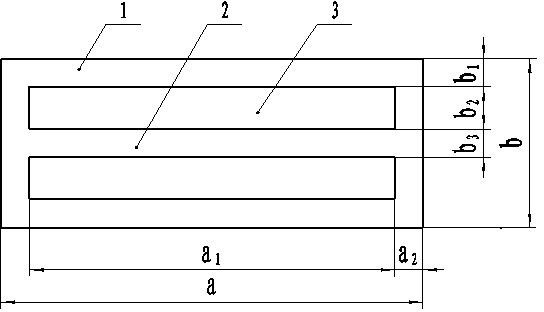

[0022] A coal gangue foam concrete block for wall self-insulation, consisting of a high-strength shell and a core material, is characterized by:

[0023] The high-strength casing is a high-strength gangue foam concrete casing 1 . The material of the high-strength gangue foam concrete shell 1 has a density of 1350 kg / m 3 The high-strength coal gangue foam concrete, the shape of the high-strength coal gangue foam concrete shell 1 is a cuboid with ribs 2 in the middle without closed upper and lower ends, the length a of the cuboid is 600mm, the width b is 200mm, and the height h is 200mm, the wall thickness b1 in the long direction, the wall thickness a2 in the width direction and the thickness b3 of the middle rib 2 are both 20mm.

[0024] The material of the core material is a density of 80kg / m 3 The core material is two cuboids of the same size, the length a1 of each cuboid is 560 mm, the width b2 is 70 mm, and the height h is 200 mm. The two core materials are respective...

Embodiment 2

[0027] A coal gangue foam concrete block for wall self-insulation, consisting of a high-strength shell and a core material, is characterized by:

[0028] The high-strength casing is a high-strength gangue foam concrete casing 1 . The material of the high-strength gangue foam concrete shell 1 has a density of 1100 kg / m 3 The high-strength coal gangue foam concrete, the shape of the high-strength coal gangue foam concrete shell 1 is a cuboid with ribs 2 in the middle without closed upper and lower ends, the length a of the cuboid is 600mm, the width b is 180mm, and the height h is 250mm, the wall thickness b1 in the long direction and the wall thickness a2 in the width direction and the thickness b3 of the middle rib 2 are both 25mm.

[0029] The material of the core material is a density of 150kg / m 3 The ultra-low density foam concrete, the core material is two cuboids of the same size, the length a1 of each cuboid is 550mm, the width b2 is 52.5mm, and the height h is 250mm...

Embodiment 3

[0032] A coal gangue foam concrete block for wall self-insulation, consisting of a high-strength shell and a core material, is characterized by:

[0033] The high-strength casing is a high-strength gangue foam concrete casing 1 . The material of the high-strength coal gangue foam concrete shell 1 has a density of 900 kg / m 3 The high-strength coal gangue foam concrete, the shape of the high-strength coal gangue foam concrete shell 1 is a cuboid with ribs 2 in the middle without closed upper and lower ends, the length a of the cuboid is 600mm, the width b is 200mm, and the height h is 200mm, the wall thickness b1 in the long direction, the wall thickness a2 in the width direction, and the thickness b3 of the middle rib 2 are all 30mm.

[0034] The material of the core material is a density of 230kg / m 3 The ultra-low density foam concrete, the core material is two cuboids of the same size, the length a1 of each cuboid is 540mm, the width b2 is 55mm, and the height h is 200mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com