Precision casting waste sand reusing method

A technology of precision casting and waste sand, which is applied in the direction of casting molding equipment, manufacturing tools, solid waste management, etc., can solve the problems of precision casting waste sand polluting the environment, so as to promote circular low-carbon economy, save mineral resources, and promote health The effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1

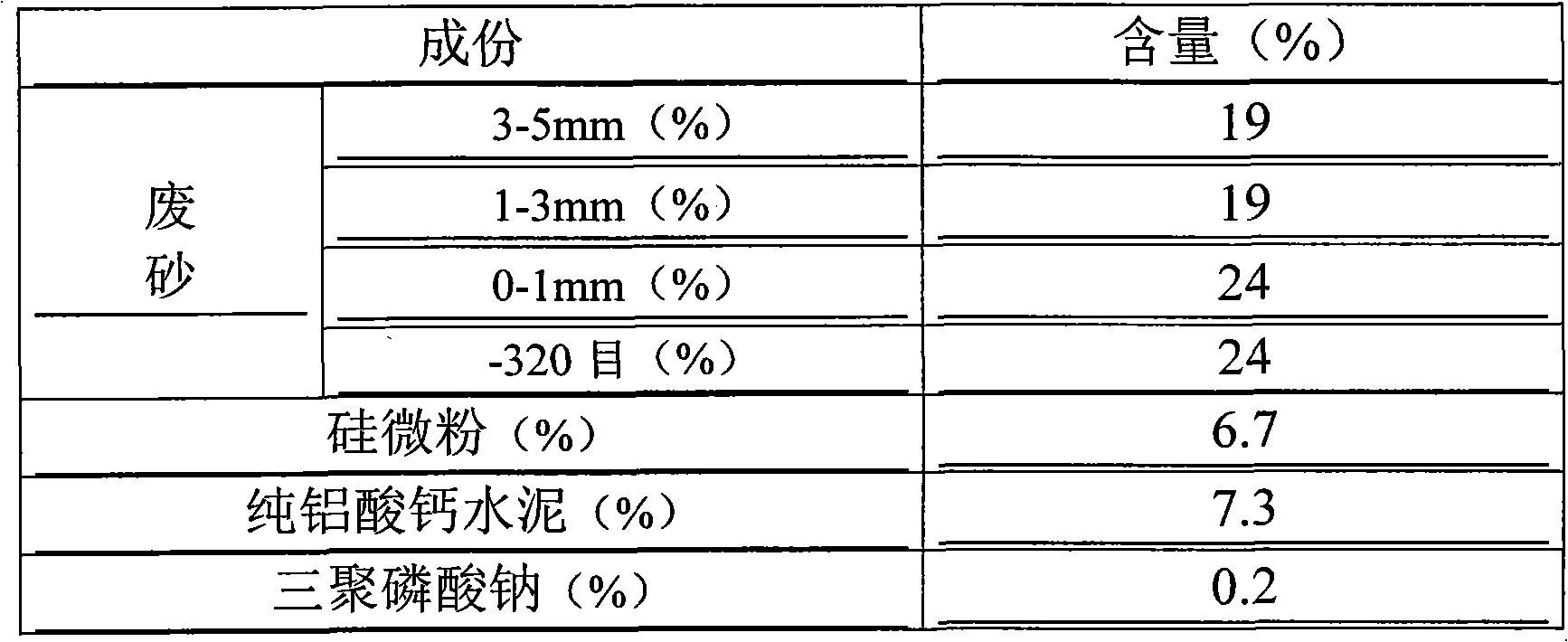

[0018] After washing and drying the waste sand of precision casting, it is crushed by a jaw crusher, and screened for later use after iron removal. Then carry out batching according to the particle gradation shown in Table 1, and add silica micropowder, pure calcium aluminate cement and sodium tripolyphosphate. Finally, mix and homogenize to obtain qualified refractory castables.

[0019] Table 1

[0020]

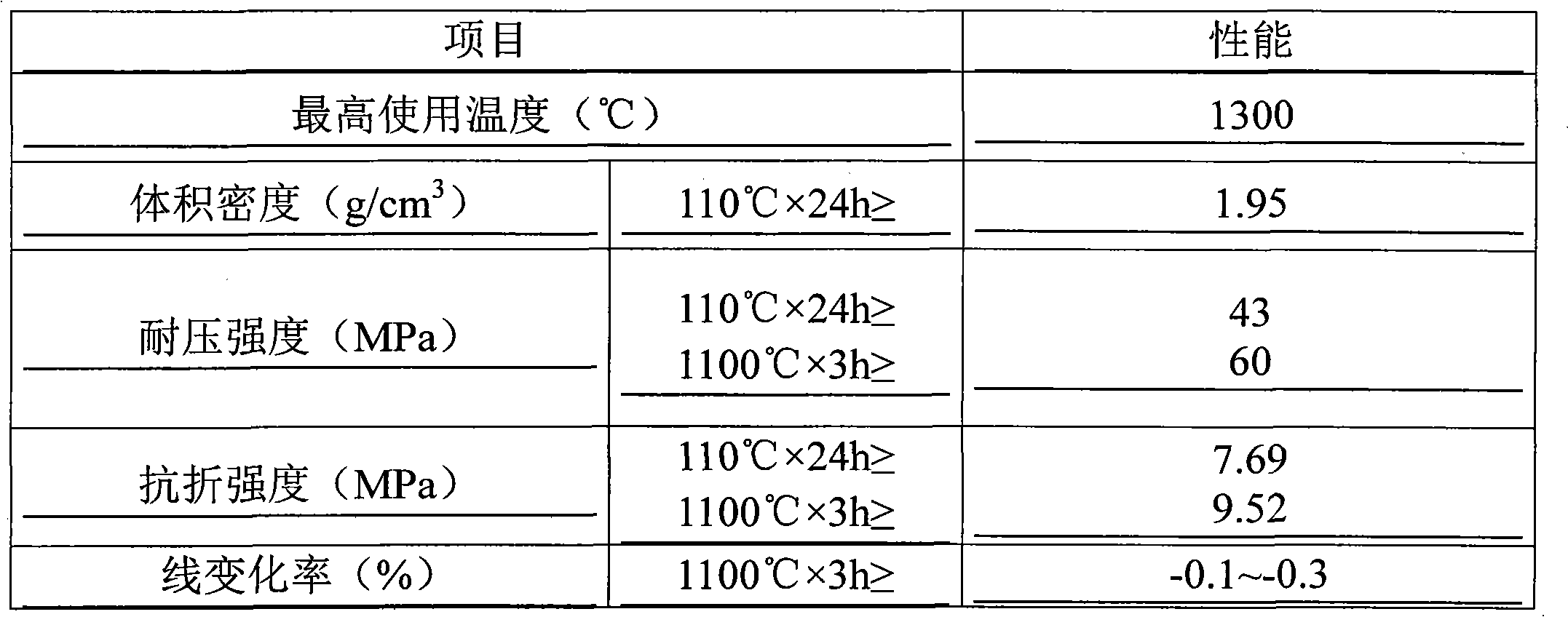

[0021] Take the refractory castable of this example, add 6% tap water and mix evenly, make a refractory castable test block through a vibrating table, and naturally cure it at room temperature, and then test its related properties. The results are shown in Table 2.

[0022] Table 2

[0023]

Embodiment 2

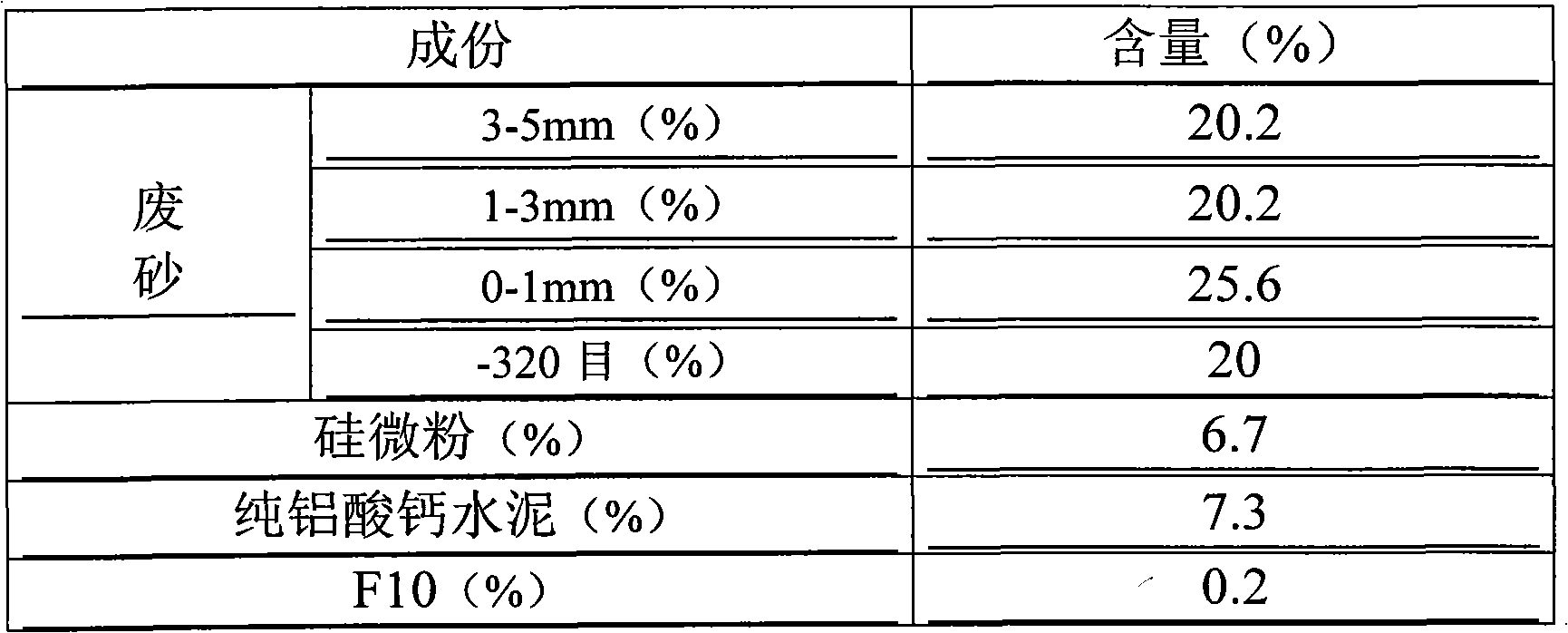

[0025] After washing and drying the waste sand of precision casting, it is crushed by a jaw crusher, and screened for later use after iron removal. Then carry out batching according to the particle gradation shown in Table 3, and add silicon micropowder, pure calcium aluminate cement and sodium lignosulfonate (F10). Finally, mix and homogenize to obtain qualified refractory castables.

[0026] table 3

[0027]

[0028] Take the refractory castable of this example and add 7% tap water to mix evenly, make a refractory castable test block through a vibrating table, and naturally cure it at room temperature, and then test its related properties. The results are shown in Table 4.

[0029] Table 4

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com