Anticorrosion expansion compacting agent composition and preparation method thereof

A technology of composition and compacting agent, which is applied in the field of anti-corrosion expansion compacting agent composition and its preparation, to achieve the effects of osmotic crystallization, adsorption of potassium and sodium ions, and improvement of self-protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

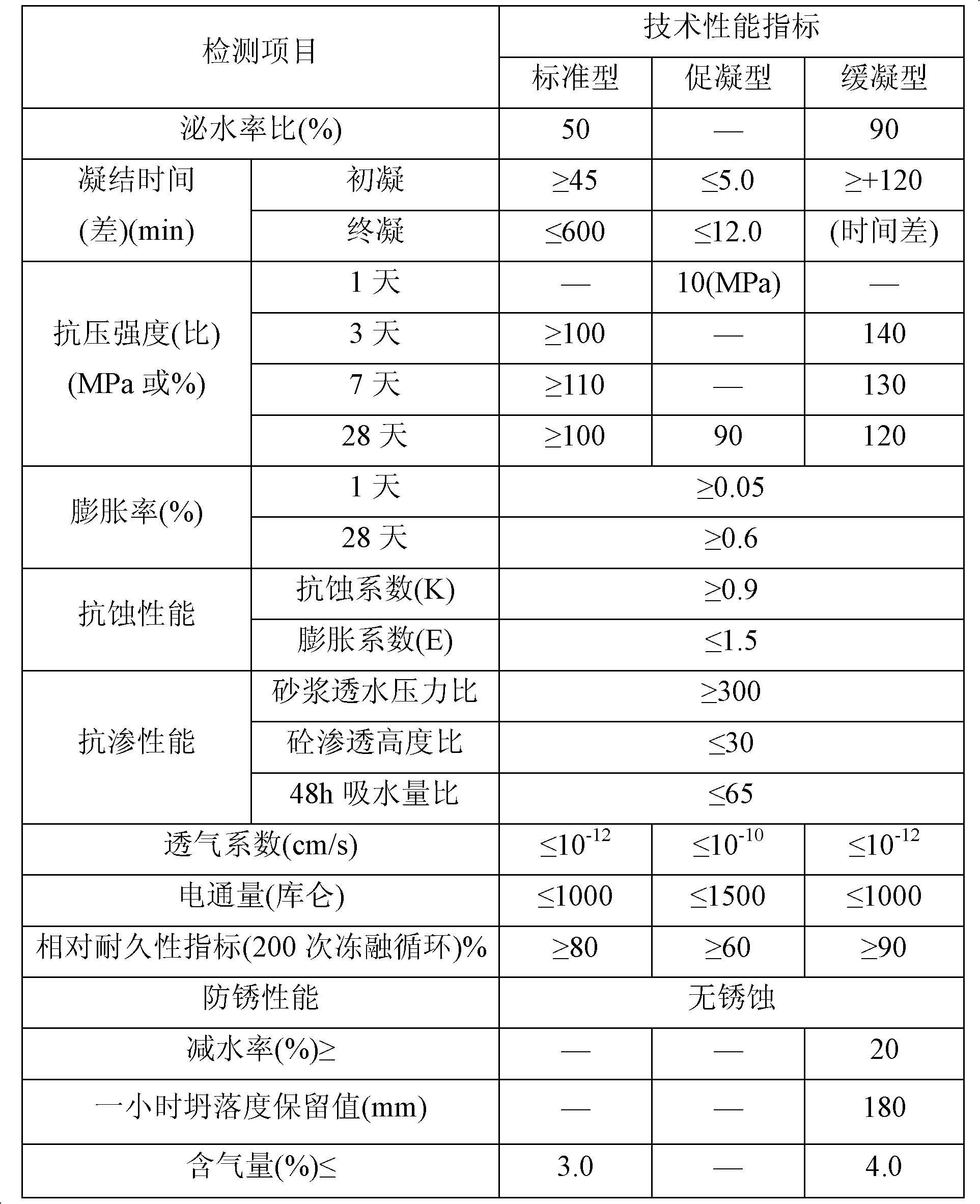

Image

Examples

Embodiment 1

[0045] Production of standard anti-corrosion expansion and compacting agent:

[0046] Calculated by weight percent of the anti-corrosion expansion compacting agent composition, the proportioning is:

[0047] 42.0% aluminum sulfate mixture, 10.0% aluminum hydroxide, 5.0% zirconium sulfate mixture, 5.0% zirconium dioxide, 10.0% magnesium sulfate mixture, 5.0% titanium sulfate mixture, 5.0% lithium bromide, 3.0% triethanolamine oleate , 10.0% polycarboxylate superplasticizer, 5.0% zinc sulfate, wherein the carrier of each mixed solution is water, and the concentration of salt or additive contained therein is 40±5%.

[0048] Preparation:

[0049] a. Preparation of aluminum sulfate mixed solution: use 800kg of fly ash containing 17% aluminum oxide, add 200kg of lye with 30% NaOH content, carry out alkali dissolution in a furnace at 650°C ± 30°C for two hours, and discharge After cooling to 60°C, pulverize and ball mill, rinse to remove silicon, and suction filter to obtain alumin...

Embodiment 2

[0055] Preparation of anti-corrosion expansion and compacting agent coagulation-accelerating products:

[0056] Add 6600kg of aluminum sulfate mixed solution into the reaction kettle, raise the temperature to 80℃±2℃, turn on the mixer, add 1000kg of zirconium sulfate mixed solution, 500kg of magnesium fluorosilicate, 400kg of triisopropanolamine, and aminoiodate superplasticizer 500kg, sodium fluoride 1000kg, react for three hours after adding, cool down to 45°C±3°C, keep warm for one hour to get anti-corrosion expansion compacting agent coagulation-accelerating product.

Embodiment 3

[0058] Preparation of anti-corrosion swelling and compacting agent retarded products:

[0059] Add 5000kg of aluminum sulfate mixed solution into the reaction kettle, raise the temperature to 80℃±2℃, turn on the mixer, add 1000kg of zirconium oxychloride mixed solution, 500kg of magnesium fluoride mixed solution, 500kg of lithium carbonate mixed solution, 500kg of diethanolamine, 1000kg of Polycarboxylate superplasticizer mixed solution, 500kg titanium dioxide mixed solution, react for 3 hours ± 10 minutes after adding, cool down to 45℃±3℃, then add 500kg sodium gluconate, 200kg sucrose and 300kg citric acid, keep warm after completely dissolving After 1 hour, the anti-corrosion expansion compacting agent retarding pumping type product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com