Production method and use of camellia seed polysaccharide

A production method and technology for camellia seeds, which are applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of large-scale application, high price, low extraction yield, etc., and achieve significant social and economic benefits. The effect of high efficiency, high utilization rate of raw materials and high extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1000g defatted camellia oleifera cake, soaked in 6000ml 70% (v / v) ethanol solution three times at 30°C, each time for 30 minutes, combined soaking liquid, vacuum concentration, spray drying to obtain 78 grams of product with tea saponin as the main component; The residue after the soaking process was soaked three times at 40° C. with 6000 ml of 50% ethanol for 30 minutes each time. The soaking liquid was combined, concentrated in vacuum, and spray-dried to obtain 91 grams of the product of camellia oleifera polysaccharide as the main component.

Embodiment 2

[0028] 1000g defatted camellia oleifera cake, 4000ml 98% (v / v) methanol solution, soaked three times at 40°C, each time for 30 minutes, combined soaking liquid, concentrated in vacuo, spray-dried to obtain 85g of tea saponin with a content of 82%; The soaked residue was soaked three times at 40° C. with 4000 ml of 30% ethanol, each time for 30 minutes. The soaking liquids were combined, vacuum concentrated, and spray-dried to obtain 88 g of Camellia oleifera polysaccharides with a sugar content of 68%.

Embodiment 3

[0030] 1000g defatted camellia oleifera cake, 5000ml 80% (v / v) methanol solution, soaked three times at 35°C, each time for 30 minutes, combined the soaking liquid, vacuum concentrated, spray-dried to obtain 83g of tea saponin with a content of 73%; The residue after soaking was soaked three times at 40° C. with 5000 ml of 45% ethanol for 30 minutes each time. The soaking liquids were combined, vacuum concentrated, and spray-dried to obtain 95 g of Camellia oleifera polysaccharides with a sugar content of 71%.

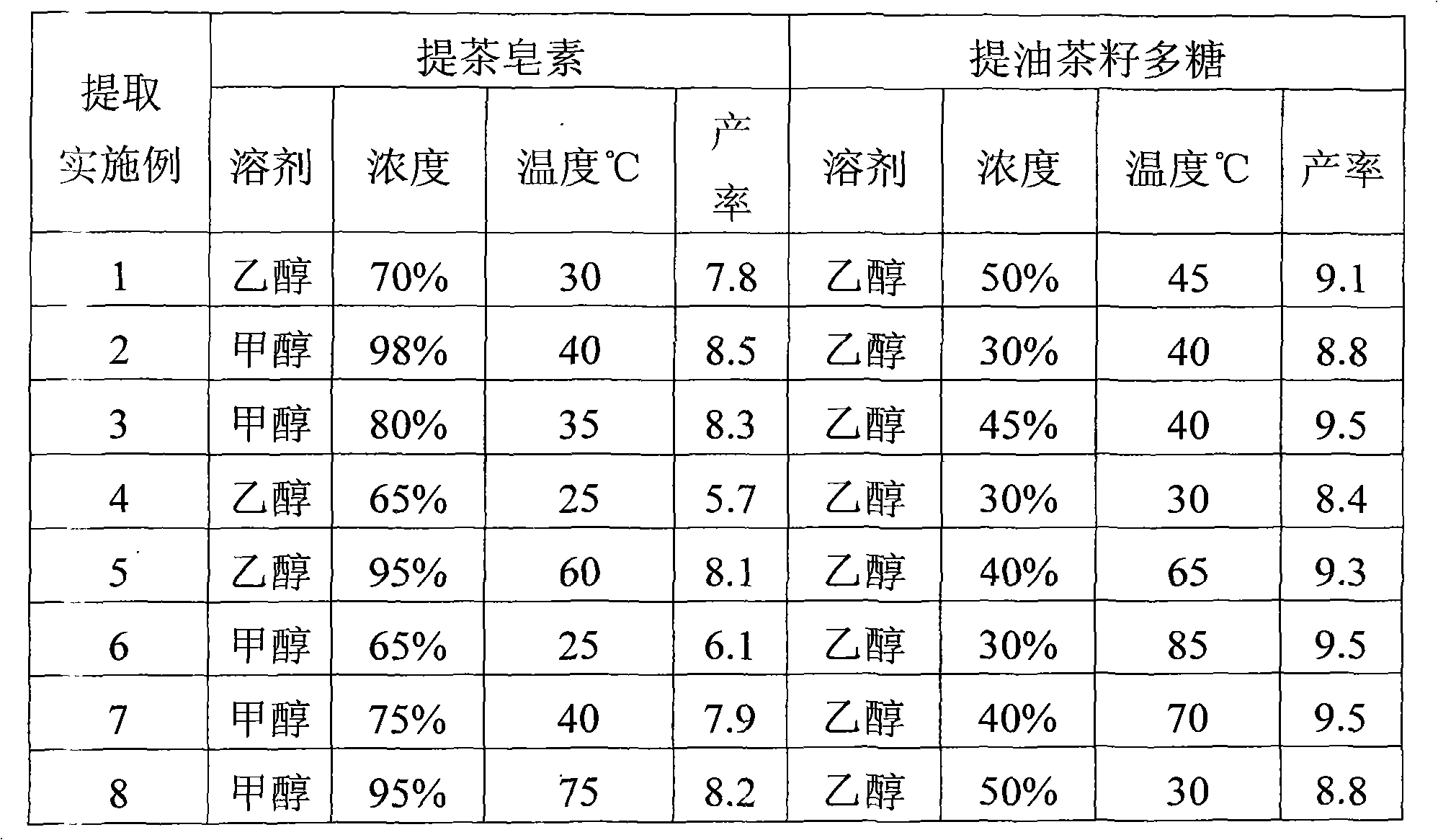

[0031] Extraction Example 4 to Extraction Example 8: see the following list of examples, and the rest of the methods are the same as above.

[0032] Extraction conditions and result list of Examples 1-8

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com